How to Improve Grinding Efficiency: 5 Key Factors Analyzed

3644Unlock peak grinding performance. This guide explores the main factors y can control, from material properties to operational parameters, to improve efficiency.

View detailsSearch the whole station Crushing Equipment

In the gold mining industry, carbonaceous gold ore is known as the “Silent Thief.” High gold grades may appear in geological reports, yet recovery rates can plummet below 30% due to the dreaded preg-robbing effect. The natural organic carbon in the ore acts like a sponge, stealing dissolved gold before it can be recovered. Based on decades of experience addressing this issue, the following overview outlines carbonaceous gold ore treatment strategies—ranging from simple chemical blinding to advanced roasting—designed to transform a loss-making mine into a profitable operation.

Carbonaceous gold ore is a complex type of refractory ore containing naturally occurring organic carbon. This carbon acts identically to the activated carbon we intentionally add in processing plants. It absorbs the gold-cyanide complex during leaching, a phenomenon we call the preg-robbing effect. If you do not neutralize this natural carbon, it will rob the gold from the solution and carry it out to the tailings dam.

The core problem here is competition. In a standard cyanidation process, you dissolve gold into a liquid state and add activated carbon to absorb it. However, in carbonaceous ores, the “bad carbon” (organic matter) is already present. It is often faster and more aggressive than your added carbon. The gold dissolves perfectly fine, but you never see it because it gets “robbed” immediately. The severity of this issue is measured by the Preg-Robbing Index (PRI). Understanding your ore’s PRI is the first step to stopping the theft.

Understanding the enemy is half the battle.

| Carbon Type | Characteristics | Impact on Recovery | Treatment Difficulty |

|---|---|---|---|

| Elemental Carbon | Graphite, resemble activated carbon | High Preg-robbing | High |

| Organic Acids | Humic acids | Consumes reagents | Medium |

| Hydrocarbons | Oil-like substances | Coats gold particles | Low to Medium |

There is no “magic pill” for carbonaceous gold ore treatment; you must match the method to the carbon’s activity level. Based on 50 years of industry evolution, we don’t just try one method; we often combine them. Effective removal or suppression involves a spectrum of strategies, ranging from “snatch games” using stronger carbon to physical separation via flotation, or total destruction via roasting.

For example, we might blend the ore to lower the carbon grade and then use chemical agents. For extremely difficult ores, we might float a concentrate and roast only that small portion. Here are the core strategies we will explore in depth:

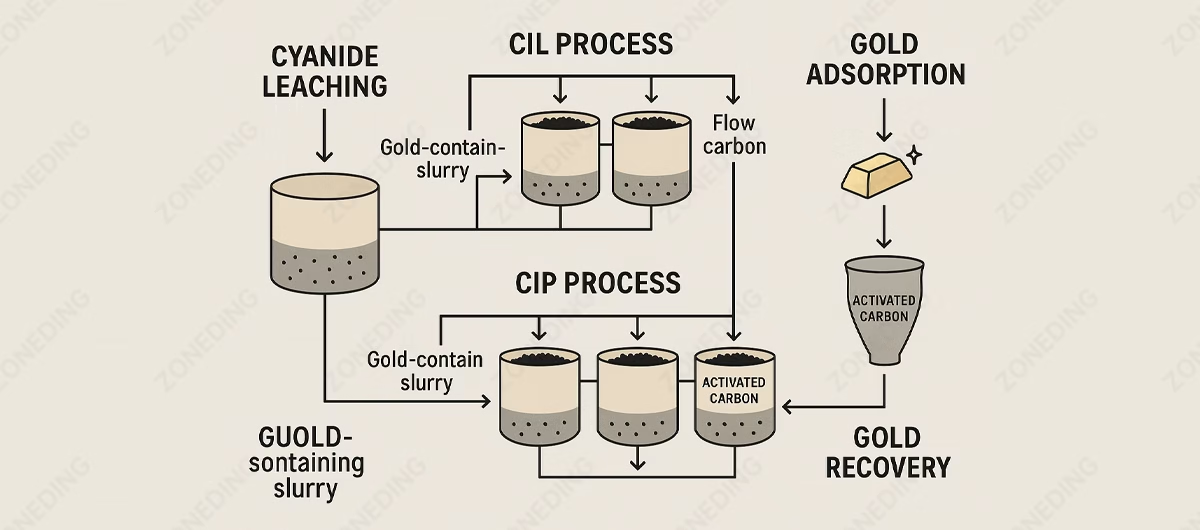

For mild to moderate carbonaceous ores, you must use Carbon-in-Leach (CIL), never Carbon-in-Pulp (CIP). Many inexperienced design institutes make the mistake of recommending CIP, but this is suicide for carbonaceous ore. In CIP, leaching happens before adsorption. The natural carbon steals the gold in the first tank before it ever reaches your adsorption circuit.

Gold CIL Plant technology solves this by allowing simultaneous leaching and adsorption. This enables you to play a “snatch game” against the natural carbon. As soon as the gold atom dissolves, it has two choices: stick to the natural “bad” carbon or stick to your added “good” carbon. You must rig the game so your carbon wins. This is the most fundamental defense against preg-robbing.

To make CIL work, you need to be aggressive with your parameters. Standard settings will fail.

Yes, adding kerosene or diesel acts as a “blinding agent” that passivates the natural carbon. We often call this the “poor man’s lifesaver.” The hydrocarbons in the kerosene selectively adsorb onto the surface of the organic carbon in the ore. This forms an oily film that blocks the active sites, preventing them from absorbing the gold-cyanide complex.

This is the most cost-effective solution for mines that cannot afford a roasting plant. It works best on ores with low to moderate preg-robbing indices. However, the application technique is critical. You cannot just dump diesel into the tank and hope for the best. You need precise conditioning in Mixer tanks.

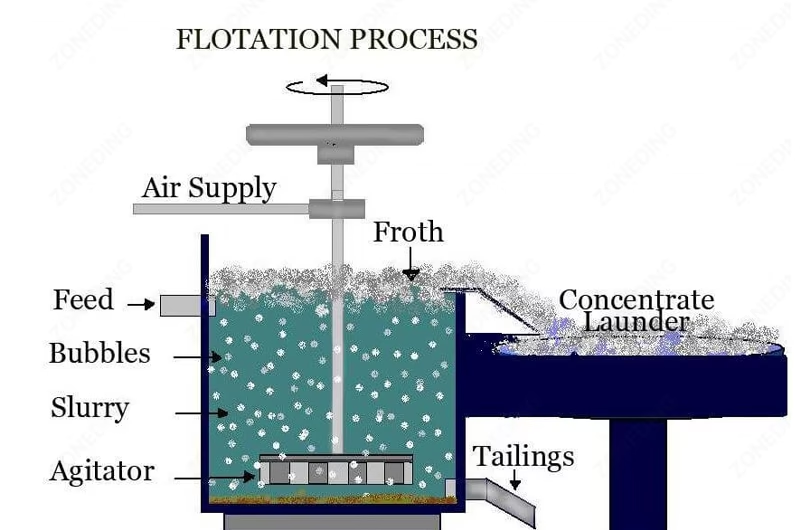

Flotation decarbonization uses “reverse thinking” to physically remove the problem. Instead of fighting the carbon chemically, we use Flotation Machines to float the carbonaceous matter out of the slurry. This prevents the carbon from ever entering the leaching tanks. This method is highly effective when the carbon can be easily separated from the gold-bearing minerals.

This strategy requires a clear understanding of where your gold is hiding. Is it in the carbon? Or is it in the sulfides? Depending on the mineralogy, we choose one of two paths.

If your mineralogy shows that the organic carbon is barren (contains no gold), you are in luck.

Often, gold is locked inside sulfides that are associated with carbon.

Oxidative roasting is the only solution for high-grade ores with extreme preg-robbing indices. This process involves heating the ore to 650°C – 700°C in a Rotary Klin. The intense heat burns the organic carbon into carbon dioxide (CO2), permanently destroying its ability to steal gold. It also oxidizes sulfides, liberating refractory gold.

Roasting is expensive and technically demanding. It is a “nuclear option” because it destroys the problem completely. However, it comes with high energy costs and environmental permitting challenges. It is usually reserved for large-scale mines with high gold grades that can justify the investment.

Operating a roaster is a delicate balancing act.

High recovery does not always mean high profit. You must balance the cost of treatment against the value of the recovered gold. Sometimes, a simple Ball Mill grinding circuit combined with blending is more profitable than a complex roasting plant. The decision hinges on your Preg-Robbing Index (PRI) and ore grade.

Do not blindly chase 95% recovery if it costs you more than the gold is worth. For many miners, the “Blending Strategy” is the smartest economic move. This involves establishing a strict geological model and mixing carbonaceous ore with oxide ore (e.g., 1:4 ratio). This dilutes the concentration of “bad carbon” to a level where a standard CIL circuit can handle it.

| Scenario | Ore Characteristics | Recommended Process | Cost Level |

|---|---|---|---|

| Scenario 1 | Low PRI | CIL + Kerosene Blinding | Low |

| Scenario 2 | Medium PRI | CIL + Kerosene + Blending | Medium |

| Scenario 3 | High PRI + High Grade | Flotation + Roasting | High |

| Scenario 4 | High PRI + Low Grade | Abandon / Heap Leach (if feasible) | Risk of Loss |

Q1: What is the Preg-Robbing Index (PRI)?

The PRI is a laboratory measurement that determines how active the natural carbon in your ore is. It involves spiking a sample with a known amount of gold and measuring how much is “stolen” by the ore. A high PRI indicates severe recovery issues.

Q2: Can I use diesel instead of kerosene?

Yes, diesel works similarly to kerosene as a blinding agent. However, kerosene generally disperses better in the slurry. You must use a surfactant with either option to ensure the oil coats the carbon effectively.

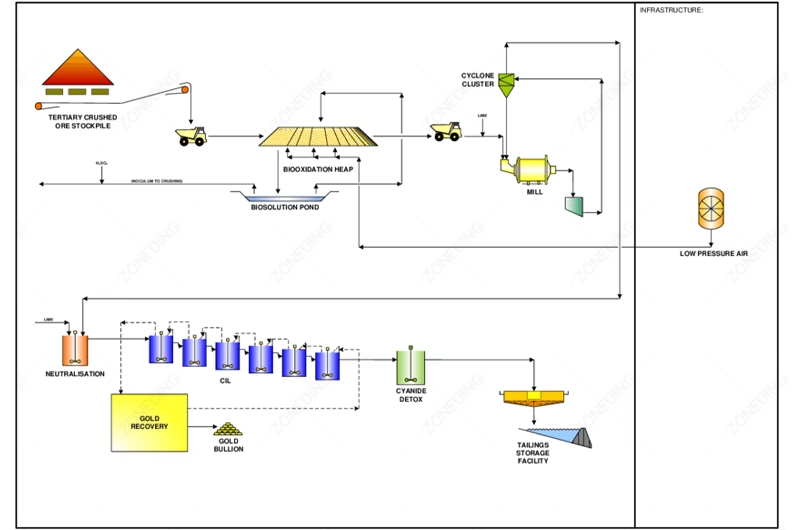

Q3: Does bio-oxidation remove carbon?

Bio-oxidation primarily targets sulfide minerals (eating the sulfur). However, the bacterial activity and the environment created can partially passivate organic carbon surfaces. It is a good middle-ground option for double refractory ores (sulfide + carbon).

Q4: Why not just use chlorine to destroy the carbon?

Chlorination was used in the past, but it is extremely corrosive, toxic, and expensive. Modern environmental regulations and the high cost of chlorine gas have made this method largely obsolete in favor of roasting or CIL.

ZONEDING Machine is a leading manufacturer of mineral processing equipment in China. We specialize in solving complex metallurgical challenges, including carbonaceous gold ore treatment. With over 20 years of experience, we provide complete solutions ranging from crushing and grinding to CIL plants and roasting kilns. Our goal is to help you maximize recovery and profitability.

Contact ZONEDING today to optimize your gold recovery process.

Unlock peak grinding performance. This guide explores the main factors y can control, from material properties to operational parameters, to improve efficiency.

View detailsThis article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsLearn the full dolomite processing line, from primary crushing with a jaw crusher to fine grinding with a Raymond mill. Select the right equipment for your plant.

View detailsWant to maximize gold recovery? These 3 machines are essential. Learn about the shaking table, spiral concentrator, and jig for efficient gravity separation.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy