How Iron Ore Powers the Global Economy and Industry

3567Discover what iron ore is, how it's mined, and why it's the critical backbone of the global economy. Learn how it's transformed into steel for everything.

View detailsSearch the whole station Crushing Equipment

Designing a Copper Ore Beneficiation Process Design requires a rigorous analysis of micro-mineralogical characteristics rather than relying on generalized rules. The traditional approach of simply floating sulfides and leaching oxides often fails to address the complexities of modern ore bodies, such as high-carbonate oxides or refractory mixed ores. Successful mineral processing depends on differentiating between minerals like chalcopyrite, chalcocite, and malachite, and understanding their specific association with gangue materials. This guide explores the engineering logic required to customize beneficiation circuits for maximum recovery rates in the changing landscape of 2026.

The foundation of any effective beneficiation process lies in distinguishing the oxidation ratio of the ore. Treating “Mixed Ore” as a single category often leads to significant metal loss. A mixed ore containing 15% oxide behaves fundamentally differently from one with 45% oxide content. Phase analysis reveals whether copper exists in a “free” state, such as malachite which is easily leached, or in a “combined” state, locked within silicates and resistant to standard processing methods.

Ignoring these distinctions can result in sulfide processing lines losing oxidized metal to tailings, or heap leach pads failing due to the slow dissolution of secondary sulfides. Phase analysis serves as the critical roadmap for process design.

| Copper Phase | Mineral Examples | Recommended Process | Key Equipment |

|---|---|---|---|

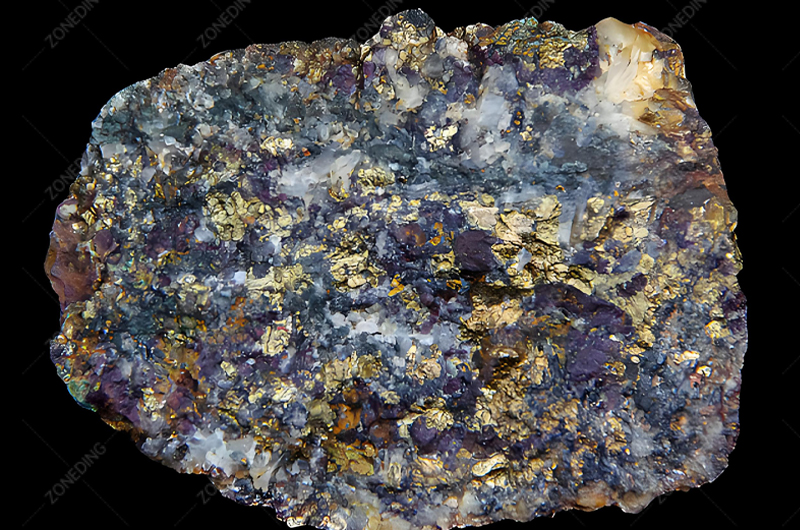

| Primary Sulfide | Chalcopyrite, Bornite | Standard Flotation | Flotation Machine |

| Secondary Sulfide | Chalcocite, Covellite | Flash Flotation + Regrind | Hydrocyclone |

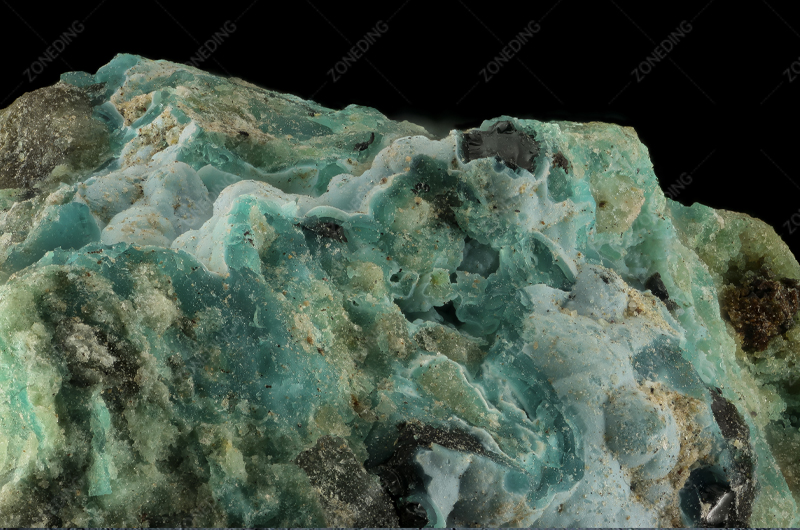

| Free Oxide | Malachite, Azurite | Acid Leaching (SX-EW) | Agitation Tank |

| Refractory Oxide | Chrysocolla | LPF or Roasting | Rotary Kiln |

Sulfide Copper Flotation requires more than a standard “Crush-Grind-Float” approach; preventing the over-grinding of soft minerals is paramount. While Chalcopyrite floats relatively slowly, minerals like Chalcocite and Bornite float rapidly and are physically softer. Processing these diverse minerals in a Ball Mill for the same duration often causes the softer Chalcocite to slime. Once slimed, these fine particles fail to attach to air bubbles, leading to metal loss.

Flash Flotation offers a solution to this issue. Installing a Flash Flotation cell directly between the ball mill discharge and the Hydrocyclone allows for the immediate recovery of coarse, liberated high-grade copper minerals. These minerals are turned into concentrate instantly and never re-enter the grinding circuit. This process reduces the load on the downstream flotation circuit and lowers filtration costs, as coarse concentrate dewaters more efficiently than fine slime.

The Arsenic Challenge:

Many deposits, particularly in South America and Southeast Asia, contain Enargite (Sulfide Arsenic Copper). Smelters often reject concentrate with high arsenic levels. Solutions include Oxidation Separation, using specific oxidants to create a potential difference that floats Chalcopyrite while depressing Enargite. Alternatively, Bio-Leaching utilizes high-temperature bacteria to treat the sulfide, bypassing the smelter to produce cathode copper directly.

Molybdenum Recovery:

In Porphyry Copper deposits, Molybdenite is a valuable by-product often overlooked. Molybdenite naturally floats well and follows copper into the bulk concentrate. A dedicated Molybdenum Flotation Plant separates the two by using Sodium Hydrosulfide to depress copper while floating molybdenum. It is crucial to avoid using lime in the bulk circuit if molybdenum recovery is planned, as lime depresses molybdenum.

Acid Consumption determines the viability of Copper Oxide Leaching SX-EW. While Heap Leaching is favored for its low operational costs, the presence of carbonates such as Calcite or Dolomite can render the project uneconomical. These minerals consume sulfuric acid rapidly. If acid consumption exceeds 30-40kg per ton of ore, alternative methods such as agitation leaching or sulfidization flotation become necessary.

Agitation Leaching:

For high-grade, high-carbonate ores, Agitation Leaching in high-intensity Mixer tanks allows for precise control over reaction time. This minimizes the contact time between acid and gangue minerals, optimizing acid usage compared to the month-long cycles of heap leaching.

Sulfidization Flotation:

This method involves adding Sodium Sulfide to coat oxide minerals like Malachite with a thin sulfide film, altering their surface properties to mimic sulfides. This allows the oxides to be floated using standard xanthate collectors.

Oxide deposits in certain regions often contain high levels of sticky clay or “slimes.” Sending this material directly to a crusher can cause blockages, while sending it to a heap leach pad destroys permeability, creating a “dead heap.” The effective solution involves using a Sand Washing Machine or Drum Scrubber immediately after coarse crushing. This equipment scrubs the clay from the rock. Low-grade clay is discarded, while high-grade clay is directed to a separate agitation leach circuit, ensuring the main heap remains permeable.

Mixed ores, containing both sulfides and oxides, present significant processing challenges. The standard “Sulfide First, Oxide Second” approach often fails due to the difficulty in controlling the sulfidizing agent. Sodium Sulfide (Na2S) is necessary to float oxides, but an overdose will depress sulfide minerals, reducing overall recovery.

The solution lies in the Stepwise Addition system using Electrochemical Potential (Eh) control, often referred to as the LPF (Leach-Precipitation-Flotation) logic applied to reagents. Rather than adding all chemicals at once, sulfidizers are introduced at multiple points—the head of the rougher bank, the third cell, and the scavenger. Eh sensors monitor the pulp potential to ensure the sulfide film on oxide minerals is maintained without overdosing the system. This precise control is essential for high recovery rates in mixed ore circuits.

The selection of grinding equipment is dictated by ore hardness and dissemination size. For hard, massive ores, a conventional circuit utilizing a Jaw Crusher followed by a Cone Crusher and Ball Mill provides reliability. However, for large-tonnage, lower-grade porphyry ores, a Semi-Autogenous Grinding (SAG) mill is often superior as it eliminates the need for secondary and tertiary crushing stages.

The Shift to Vertical Mills for Regrinding:

Innovation in 2026 focuses heavily on the regrinding stage. Separating copper minerals from pyrite or molybdenum often requires regrinding the rougher concentrate to 30-40 microns. Traditional ball mills are inefficient at these fine sizes. Vertical Stirred Mills (Tower Mills) are recommended for this application. They utilize media attrition rather than impact, resulting in 30-50% energy savings compared to ball mills for fine grinding, while also occupying less floor space.

Reagent selection must align with the surface physics of specific copper minerals. There is no universal collector suitable for all ore types. For clean Chalcopyrite, simple Xanthates (PAX/SIPX) are effective. However, for oxidized surfaces or mixed ores, more powerful and selective collectors such as Dithiophosphates or Thionocarbamates are required.

Frother selection is equally critical. In a flotation cell, bubble size determines carrying capacity. Coarse particles require strong frothers (like Pine Oil or MIBC) to create stable bubbles capable of supporting heavy loads. Conversely, fine particles require weaker, more brittle froths to prevent the entrainment of gangue minerals. Laboratory “locked cycle tests” are essential to verify reagent regimes, as open-circuit tests fail to account for the buildup of reagents in recycled process water.

The industry in 2026 is moving decisively towards Pre-Concentration. Bulk sorting sensors installed on conveyor belts after primary crushing are now standard in advanced plants. These sensors detect waste rock (gangue) and utilize air jets to eject it before it enters the energy-intensive grinding circuit. This technology reduces energy costs and water usage by approximately 20-30%.

Q1: How should high clay content in copper oxide ore be handled?

Fine crushing should be avoided. A washing machine or Drum Scrubber effectively removes clay from the rock. The clay and rock are then treated separately; clay typically proceeds to agitation leaching, while the clean rock is suitable for heap leaching.

Q2: Is Heap Leaching viable with acid consumption at 50kg/ton?

Generally, no. Operational costs at this level usually destroy profit margins. Sulfidization Flotation or Agitation Leaching with acid recovery systems should be investigated as alternatives if the ore grade permits.

Q3: What causes low recovery in mixed ore circuits?

Overdosing of Sodium Sulfide is a common cause. Excess sulfidizer depresses sulfide minerals. Installing Eh sensors and implementing multi-stage addition of sulfidizers ensures optimal potential without suppression.

Q4: Can Copper and Gold be processed together?

Yes. Gold associated with copper sulfides will float into the concentrate. Free gold requires a Centrifugal Concentrator in the grinding circuit to recover gravity gold before the flotation stage.

ZONEDING Machine stands as a global provider of mineral processing solutions, focusing on maximizing recovery rates through engineered precision. From high-efficiency Flotation Machines to rugged Crushing Equipment, the company equips mines to handle complex variations in copper ore. With over two decades of manufacturing experience, ZONEDING assists operations in transforming complex geology into profitable production.

Contact ZONEDING for customized copper ore testing and process design solutions.

Discover what iron ore is, how it's mined, and why it's the critical backbone of the global economy. Learn how it's transformed into steel for everything.

View detailsSelecting the correct manganese beneficiation method is the most critical decision in plant design. The choice between Gravity Separation and Magnetic Separation is determined strictly by the ore's mineralogy, specifically density and magnetic pr...

View detailsThis article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsMaking the right choice is critical. We break down the 4 main cone crusher types and guide you through key selection factors like feed size and capacity.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy