Search the whole station Crushing Equipment

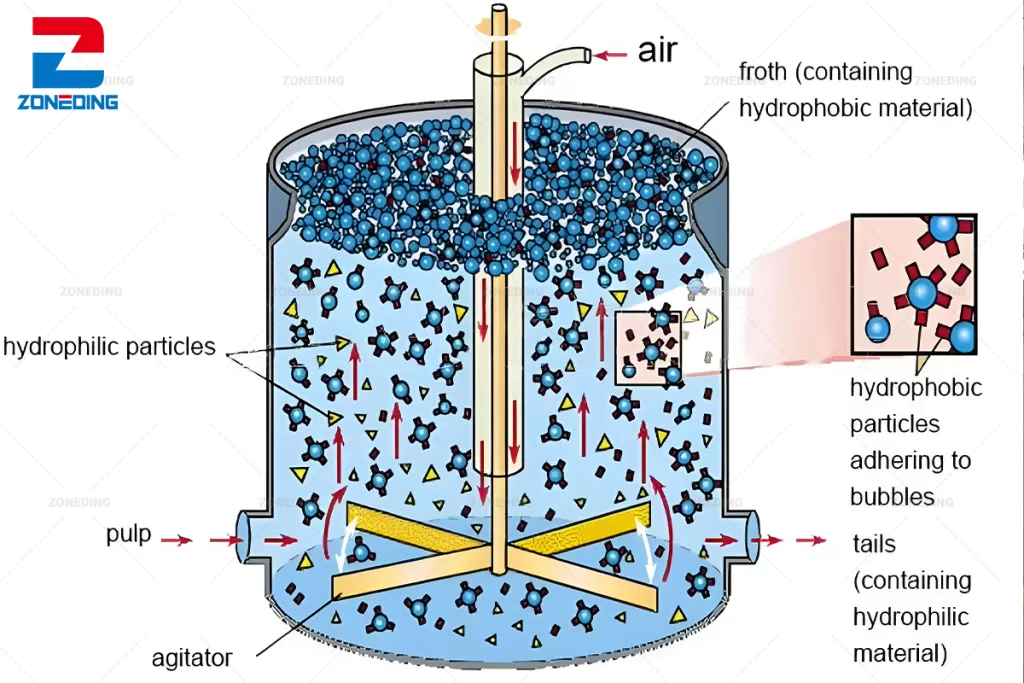

The mining agitator, also called mixer, is a kind of agitating equipment used for ore pulp agitation before flotation operation, so that ore pulp and reagent are fully mixed.

It can also be used for stirring other non-metallic minerals.

Mixing barrels are very common in metal and non-metal beneficiation, such as flotation beneficiation, hydrometallurgy, rare and precious metal leaching and extraction, and are also used in many sewage treatment and production of some chemical raw materials.

A tank mixers agitators system is a piece of industrial equipment designed to stir or blend fluids, solids, or both inside a large vessel or tank.

In the mining world, its primary purpose is to agitate slurry. This means it creates motion to achieve a specific process goal. This goal could be simple, like preventing heavy mineral particles from settling at the bottom of a storage tank.

Or it could be more complex, like ensuring every particle of gold ore comes into contact with a chemical leaching solution.

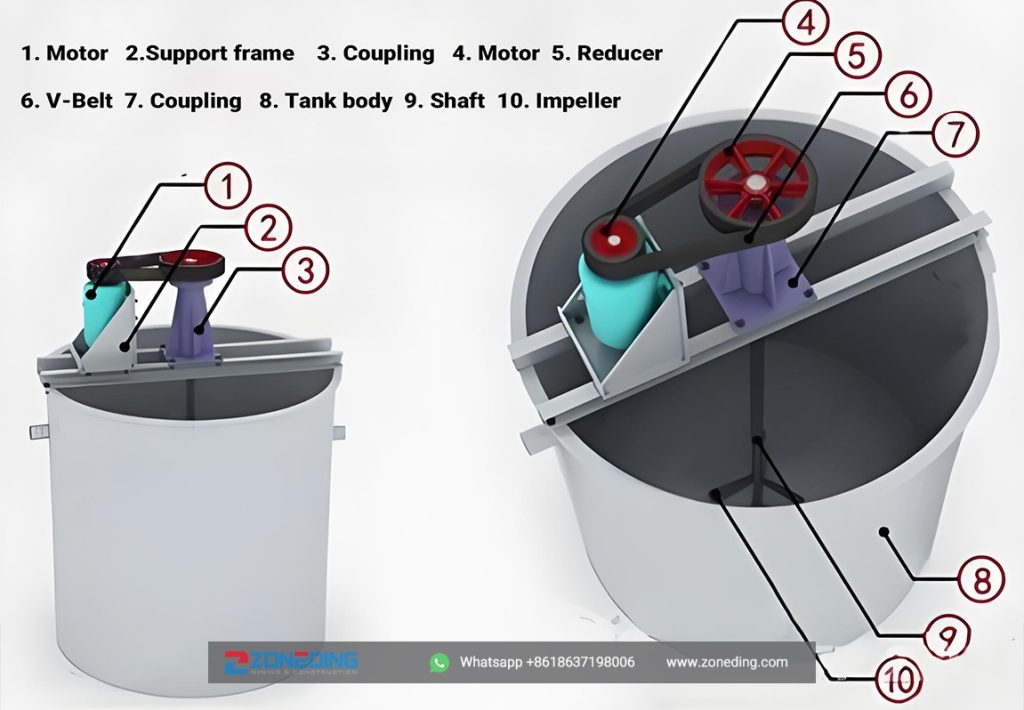

It is a system composed of a motor, a gearbox, a long shaft, and an impeller (the propeller-like part) that does the actual work inside the mixing tank with agitator.

Without it, many mineral processing circuits would simply not work.

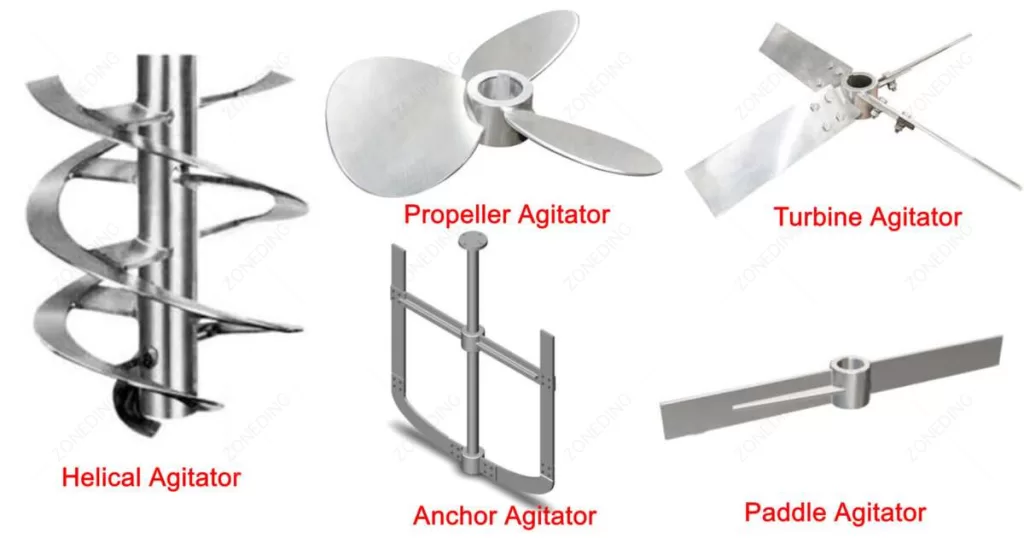

Not all agitators and mixers are created equal. The most significant difference lies in the design of the impeller, which creates the flow inside the tank. Choosing the right impeller type is essential for efficiency. A poor choice can lead to high energy costs, incomplete mixing, and lower mineral recovery.

| Impeller Type | Flow Pattern | Best For… | Why it matters for you |

|---|---|---|---|

| Hydrofoil | Axial (High Efficiency) | Solids suspension, blending | Uses the least power to keep your valuable minerals from settling. |

| Pitched Blade Turbine | Axial (High Pumping) | General purpose mixing, heat transfer | A versatile, all-around choice for many slurry applications. |

| Rushton Turbine | Radial (High Shear) | Gas dispersion (flotation), emulsification | Perfect for when you need to mix air or chemicals aggressively into the slurry. |

| Anchor/Helical | Close Clearance | High viscosity slurries | Necessary for thick, paste-like materials that won’t flow easily. |

Axial flow impellers push the slurry straight down the middle of the tank, which then flows up the sides. This is excellent for keeping solids suspended with the least amount of power. It creates a full top-to-bottom turnover. Radial flow impellers push the slurry outwards toward the tank walls. This creates high shear, which is great for breaking up clumps or dispersing gas bubbles, a vital process for flotation.

At ZONEDING, our engineers analyze your specific slurry and process goals to select the perfect impeller design.

Industrial agitators are used everywhere in a modern mining plant where you have a liquid and a solid that need to be mixed. Their role is central to the success of many processes.

Here are some of the most common applications you will find:

Mining mixer is used for mixing pulp before flotating separation work, which mixes the pulp with medicament sufficiently for mineral selection. The mixing tank can also used for mixing other non-metallic minerals. It is applied in the material with density not higher than 30% (calculated by weight) and fixed material size less than 1 mm. It is flat-bottomed barrel with mechanical mixing method by radiant circular spiral impeller.

Compact structure and reliably sealing. Besides, there is an ash damper installed at the mouth of the discharging gate, which can prevent water and flog to enter in.

It has advantages of evenly mixing, sector shape of propeller and large contacting proportion.

There are many rows of nozzles, which can guarantee water to flow evenly.

An agitating tank, also known as a mixer or blending tank, is used in industrial processes to ensure thorough mixing of materials. Its main functions are:

An industrial agitator appears simple, but it is a robust system of several key parts working in harmony. Understanding this structure helps with maintenance and troubleshooting.

The working principle of a mixers agitators system is straightforward but effective. The system’s job is to convert electrical energy into the mechanical energy of fluid motion. The process starts with the electric motor, which provides high-speed rotational power. This power is fed into a gearbox. The gearbox is critical; it acts like the transmission in a truck, reducing the high speed of the motor to a much slower rotational speed while dramatically increasing the torque. This high torque is what gives the agitator the raw strength to move dense, heavy slurry.

This low-speed, high-torque power is then transferred down a long, solid steel shaft. At the end of the shaft is the impeller. As the impeller rotates, its specially designed blades push against the slurry, creating a powerful flow pattern inside the tank. This continuous flow lifts particles from the bottom, blends liquids together, and creates the uniform mixture your process needs to be efficient.

The Agitating Tank is composed of a motor, an impeller, a stator, a bearing and the like, and is stirred by a mechanical stirring method of a flat bottom barrel-shaped radiation circulating spiral impeller. When the agitating tank is working, the motor traction triangle belt drive device drives the impeller to rotate, and the slurry and the medicament are fully mixed with each other under the uniform stirring of the impeller, increasing the reaction time of the medicament on the pulp, and strengthening the reaction quality of the medicine, so that the material is obtained. Adequate mixing and mixing to prepare the necessary conditions for the next stage of flotation production.

When you select an industrial agitator, you are choosing a piece of equipment that must run 24 hours a day, 7 days a week, in a very tough environment. At ZONEDING, we build our agitators and mixers to last, focusing on features that deliver unmatched reliability and a long service life.

These are the core features of every ZONEDING tank mixer agitator:

Using the right industrial agitator provides several major advantages that directly impact your plant’s profitability. It is not just about stirring a tank; it is about process optimization. A properly designed mixing tank with agitator from a reliable agitator manufacturer like ZONEDING can be one of the best investments you make.Here are the key advantages for your operation:

| Category | Specification Model | Dimensions | Effective cubage(m³) | Rotate speed (r/min) | Motor power (kw) | Dimensions (mm) | Total weight (kg) | |

| Diameter (mm) | Height (mm) | |||||||

| Agitating tank | XB-10×10 | 1000 | 1000 | 0.58 | 390 | 1.5 | 1130×1130×1521 | 1050 |

| XB-12×12 | 1200 | 1200 | 1.18 | 390 | 2.2 | 1130×1330×1721 | 1160 | |

| XB-15×15 | 1500 | 1500 | 2.2 | 280 | 3 | 1750×1640×2190 | 1270 | |

| XB-20×20 | 2000 | 2000 | 5.6 | 210 | 5.5 | 2380×2160×2850 | 1700 | |

| XB-25×25 | 2500 | 2500 | 11.2 | 190 | 7.5 | 2990×2720×3540 | 3500 | |

| XB-30×30 | 3000 | 3000 | 19 | 140 | 18.5 | 4030×3270×3010 | 5200 | |

| XB-35×35 | 3500 | 3500 | 29 | 230 | 30 | 3920×3740×4970 | 6630 | |

| XB-40×40 | 4000 | 4000 | 45 | 210 | 37 | 4520×4320×5570 | 7830 | |

| Lifting type | XBT-10×15 | 1000 | 1500 | 1 | 510 | 2.2 | 1130×1130×2070 | 1250 |

| XBT-15×20 | 1500 | 2000 | 2.9 | 400 | 4 | 1636×1768×2785 | 1677 | |

| XBT-20×20 | 2000 | 2000 | 5.6 | 312 | 11 | 2180×2220×3015 | 3100 | |

| High-efficiency leaching tank | XF-20×20 | 2000 | 2000 | 7.07 | 82.5 | 1.5 | 2032×2032×3595 | 2400 |

| XF-25×30 | 2500 | 3000 | 13.5 | 57.6 | 2.2 | 2532×2532×4152 | 3670 | |

| XF-30×30 | 3000 | 3000 | 22.97 | 50 | 2.2 | 3180×3180×4673 | 5340 | |

| XF-35×40 | 3500 | 4000 | 35.6 | 41 | 4 | 3685×3685×5314 | 7140 | |

| XF-40×45 | 4000 | 4500 | 52.78 | 33.5 | 4 | 4185×4185×5814 | 9300 | |

| XF-45×50 | 4500 | 5000 | 74.75 | 33.5 | 5.5 | 4685×4685×6466 | 10500 | |

| XF-50×56 | 5000 | 5600 | 102.1 | 30.6 | 5.5 | 5185×5185×6975 | 12300 | |

| XF-55×60 | 5500 | 6000 | 135.4 | 24.4 | 7.5 | 5670×5670×7569 | 13500 | |

“Mixing” is the overall process of making a substance more uniform. “Agitation” is the action of inducing motion in a material to cause that mixing. Therefore, an industrial agitator is the machine that causes the mixing to happen.

A mixer can refer to the entire system (the mixing tank with agitator), while the agitator is the specific piece of equipment inside the tank (the motor, gearbox, shaft, and impeller) that does the physical work. In everyday conversation in a plant, you can use the terms interchangeably without much confusion. However, when you are speaking with an engineer or an agitator manufacturer like ZONEDING, being precise helps ensure you get exactly the right equipment for your mixing process.

In a mining plant, industrial agitators and mixers perform several vital tasks that are absolutely essential for production. Their primary role is to overcome gravity and keep solid ore particles from settling out of the slurry. If your valuable minerals sink to the bottom of a tank, they are effectively lost from the process and you lose money. This makes the agitator in tank a guardian of your recovery rate and your bottom line.

Beyond just suspension, they are crucial for many chemical processes. For instance, in a gold leaching circuit, the agitator continuously brings fresh chemical solution into contact with the surfaces of the gold-bearing particles. This action dramatically speeds up the dissolving process. They also ensure uniformity. By constantly blending the slurry, they guarantee that the density, temperature, and chemical concentration are the same throughout the entire tank. This consistency is essential for the stable and predictable operation of all the equipment that comes after the mixing tank, like pumps and flotation cells.

Choosing the right agitator for mixing is one of the most important technical decisions you will make for your plant.

Correctly sizing an agitator in a tank or a mixing pit is a complex engineering task. If the agitator is undersized, it will not have the power to keep the solids suspended, leading to “sanding,” lost production, and potential equipment damage. If it is oversized, you will waste a huge amount of money on electricity for the entire life of the plant.

The sizing process starts with detailed data about your slurry: its density (percent solids), its viscosity, and the particle size distribution of the solids. Next, we determine the level of agitation required for your process.Using this data, our ZONEDING engineers use proven industry formulas and specialized software to calculate the required power and torque. From there, we can select the appropriate motor and gearbox. We also determine the optimal impeller diameter and speed to achieve the desired mixing result in your specific tank geometry.

The final price of a tank mixer agitator is determined by several key factors.

At ZONEDING, we provide a clear breakdown of these costs so you can make an informed decision.

Good maintenance is the key to a long and trouble-free life for your mixers agitators.

At ZONEDING, we also stress the importance of proper start-up procedures. Never start an agitator that has been shut down in a tank full of settled solids without first trying to re-slurry the material with water, if possible. This prevents massive stress on the gearbox and shaft.

Question 1: Can you install an agitator in an existing tank?

Yes, absolutely. We frequently design and supply agitators to be retrofitted into existing tanks. Our engineers will need the exact dimensions of your tank, including diameter, height, and any internal structures, to design an agitator in tank that fits perfectly and performs correctly.

Question 2: How much power does an industrial agitator use?

Power consumption varies hugely, from as little as 1.5 kW for a small reagent mixer to over 250 kW for a very large mixing pit agitator in a thick slurry. The power is determined by the volume of the tank and the density and viscosity of the slurry being mixed.

Question 3: What happens if my agitator stops?

If an agitator stops in a tank full of slurry, the solids will begin to settle. If left for too long, they can form a hard, concrete-like mass at the bottom of the tank that is very difficult and expensive to remove. This is why agitator reliability is so important.

Question 4: What is the difference between a top-entry and side-entry agitator?

In mineral processing, almost all agitators are top-entry, meaning the shaft comes down from a drive unit mounted on top of the tank. Side-entry agitators are sometimes used in very large, low-viscosity storage tanks, like in the oil industry, but are not suitable for heavy mining slurries.

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy