What are the 5 essential crusher types for mineral processing?

3832Maximize efficiency in mineral processing! Uncover performance of five key crusher types, optimized for throughput, energy, and cost-saving ore reduction.

View detailsSearch the whole station Crushing Equipment

Let’s cut through the noise. A geology textbook will give you the chemical formulas for four types of iron ore. As an engineer who has built iron ore processing plants for decades, I can tell you that information is almost useless. The name of the ore does not matter. What matters is how it behaves in my machines and in the customer’s furnace. That is the only truth in this business. Understanding this difference is the line between a profitable mine and a very expensive hole in the ground.

This guide is not about geology. It is about the business reality of iron ore beneficiation. We will explore how the two main ores, Magnetite and Hematite, and their lesser-known cousins, dictate your entire beneficiation process, from the first crusher to the final product.

Before we dive into the technical details of processing, let’s be clear about the stakes. Iron ore is not just another commodity. It is the bedrock of the modern world. Its conversion into steel forms the backbone of nearly every major industry. The profitability of your iron ore beneficiation project depends entirely on your ability to produce a quality product that can feed this immense, insatiable global demand.

| Industrial Sector | Primary Product from Steel | Specific Applications & End Products | Why It’s the Pillar |

|---|---|---|---|

| Construction & Infrastructure | Structural Steel, Rebar | Skyscrapers, bridges, stadiums, tunnels, pipelines, airports, railways. | Steel’s unmatched strength-to-weight ratio and cost-effectiveness make it the only viable material for the skeleton of modern civilization. |

| Transportation | High-Strength Sheet Steel, Forged Steel | Car bodies and chassis, ship hulls, train cars, aircraft landing gear, engine blocks. | Provides the critical combination of strength, safety, durability, and formability required to move people and goods efficiently. |

| Manufacturing & Machinery | Machine-Grade & Tool Steel | Factory equipment, industrial robots, CNC machines, agricultural machinery (tractors), mining equipment (crushers, mills). | The hardness, wear resistance, and precision of steel are essential for the tools and machines that build, cut, and shape all other products. |

| Energy | High-Tensile Steel, Alloy Steel | Oil and gas pipelines, wind turbine towers, offshore drilling platforms, power plant structures, electrical transformers. | Offers the durability and resistance to high pressures and extreme environments needed to generate and transport energy reliably. |

| Consumer Goods | Stainless Steel, Coated Steel | Refrigerators, washing machines, ovens, kitchen sinks, cutlery, food cans, furniture. | Delivers the affordability, durability, and hygienic properties (in the case of stainless steel) that enable modern daily life. |

On paper, Magnetite (Fe₃O₄) and Hematite (Fe₂O₃) are just iron oxides. In the real world of mining economics, they represent two completely different business models. The industrial value and the entire beneficiation process are dictated by their fundamental physical and chemical properties, not just their iron content.

The rookie looks at the head grade; the veteran looks at the process. A high-grade hematite deposit can be a financial nightmare if it’s complex to process. A low-grade magnetite deposit can be highly profitable due to its processing simplicity.

| Feature | Magnetite (Fe₃O₄) | Hematite (Fe₂O₃) | What This Means For Your Business |

|---|---|---|---|

| Key Property | Strongly Magnetic | Weakly Magnetic or Non-Magnetic | Magnetite can be concentrated using cheap, simple, and powerful magnetic separation. Hematite cannot. |

| Typical Head Grade | Often lower (e.g., 25-40% Fe) | Can be very high (e.g., 55-68% Fe, “DSO”) or lower. | Magnetite’s low grade is easily overcome by its easy processing. Hematite’s high grade can be a trap if processing is complex. |

| Concentrate Product | Ultra-fine powder (“Pellet Feed”) | Coarse lumps and fines (“Lump” and “Fines” or “Sinter Feed”) | Magnetite requires an expensive secondary process (pelletizing). Hematite often does not. |

| Processing Complexity | Simple and elegant, but requires very fine grinding. | Can be extremely simple (crush and screen) or extremely complex (gravity, flotation). | The risk profile for hematite is much wider. You must know which type you have. |

The magnetite beneficiation process is the most elegant and straightforward in the iron ore industry. Don’t think of the ore as rock. Think of it as rock containing tiny, valuable magnets. My job is to crush the rock to powder and use a giant, cheap magnet to pick out the valuable bits. The magic is in the ore’s natural magnetism.

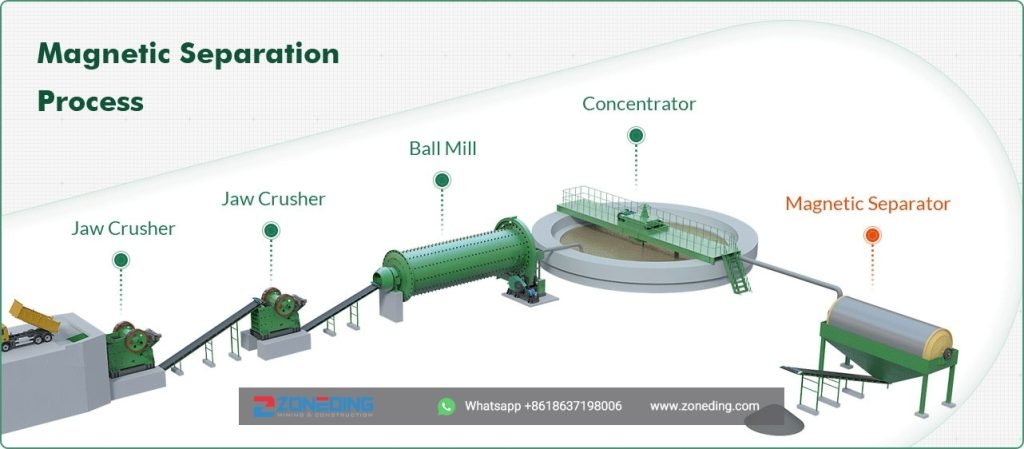

The typical beneficiation process for magnetite is a wet circuit and follows three main steps:

However, this process has a “hidden tax.” The resulting concentrate is an ultra-fine powder that cannot be directly used in a blast furnace. It must first be sent to a separate, highly energy-intensive pelletizing plant, where it is mixed with a binder and fired into hard, marble-sized pellets. This backend cost is a critical part of the overall project’s economics.

The term “hematite” is dangerously misleading because it covers two completely different business realities. The hematite beneficiation process you need depends entirely on which reality you are facing.

This is the hard, lumpy ore found in world-class deposits. The iron content is already very high (often >60% Fe). The “processing plant” for this ore is incredibly simple. It is essentially a large-scale Stone Crushing Plant. The process is just to crush the ore and screen it into different size fractions, such as “lump” (for direct furnace feed) and “fines” (for sinter feed). The required equipment is straightforward: Vibrating Feeder, Jaw Crusher, Cone Crusher, and multiple Vibrating Screen decks. The capital cost is relatively low, and the operation is simple.

This is where fortunes are lost. This type of hematite has a lower iron grade and is often mixed with silica, clay, and other impurities. It cannot be directly shipped and requires a full-scale beneficiation plant. Since hematite is only weakly magnetic, you cannot use cheap magnetic separators. You must rely on other physical properties, primarily density. This requires a complex, water-intensive plant using gravity separation equipment. Common methods include:

When a company says they have a “massive hematite deposit,” the first question must be: “What’s the flowsheet?” If they don’t have a proven, economic process, they don’t have a mine; they have a geological curiosity.

An ore’s physical properties—its hardness, toughness, and structure—are just as important as its chemical grade. These properties directly impact the design and cost of your comminution circuit (crushing and grinding). The Bond Work Index (BWI) is a standard measure of an ore’s resistance to grinding. A high BWI means the ore is hard and will require more energy and more robust equipment to process.

Crushing Stage:

Hard, competent ore requires heavy-duty primary crushing equipment. A large Jaw Crusher is the standard for this application due to its simple design and ability to handle large feed sizes and high compressive forces. Softer, more friable ores might allow for the use of different primary crusher types, but the jaw crusher remains the most reliable choice for most hard rock mining operations. In the secondary and tertiary stages, a Cone Crusher is preferred for hard ores because it handles the high stress while producing a consistent, cubical product ideal for feeding the grinding mills.

Grinding Stage:

The ore’s hardness has a massive impact on the size and power of the grinding mills. A high BWI means you need a larger diameter mill, a more powerful motor, and a higher consumption rate of grinding media (steel balls) to achieve the target fineness. For extremely hard ores, some modern plants are turning to High-Pressure Grinding Rolls (HPGR) ahead of the ball mills. An HPGR acts as a super-tertiary crusher, using immense pressure to create micro-fractures in the ore particles. This makes the ore much easier to grind in the subsequent Ball Mill, potentially reducing the overall energy consumption of the circuit by 20-30%. This is a capital-intensive decision but can pay for itself in energy savings over the life of a large-scale mine.

The steel mill is your ultimate customer. They do not buy “hematite” or “magnetite.” They buy two primary products: Sinter Feed or Pellet Feed. Your entire Iron Ore Beneficiation plant must be designed backward from the product you can economically create and sell. This is the most critical classification that determines your plant’s design.

Designing for Sinter Feed:

This product is a mix of coarse and fine particles, typically produced from crushing and screening high-grade DSO hematite, or by concentrating lower-grade hematite using gravity methods. The key requirement for good sinter feed is its physical and chemical structure. It must have a mix of particle sizes that allows air to flow through it when it’s being heated (sintered) at the steel mill. Ores that are too soft or produce too many ultra-fine dust particles during crushing make poor sinter feed. Your plant design will focus on multi-stage crushing, screening, and potentially a gravity circuit to achieve the right size distribution and grade.

Designing for Pellet Feed:

This product is the ultra-fine powder concentrate produced almost exclusively from grinding magnetite ore. The entire plant is designed to achieve one goal: grind the ore fine enough for complete liberation and then use magnetic separation to produce a very high-grade, very fine concentrate. The plant’s design is therefore dominated by the grinding and magnetic separation circuits. As discussed, this business model must also include the massive capital and operating cost of a pelletizing plant to agglomerate this fine powder into usable pellets. The best ore in the world is useless if it cannot be made into good sinter or good pellets.

To design a profitable iron ore plant, a manufacturer needs more than just the name of the ore. A vague inquiry will only get you a vague and useless budget number. To get a serious, customized technical proposal and an accurate quote, you must provide detailed data from a proper metallurgical testing program.

Come to us with this information, and our engineers can design a real plant:

Forget the simple ore names. When you look at an iron ore deposit, you must see the entire value chain: the mine, the mill, the ship, and the fire inside your customer’s furnace. The true “type” of your ore is not its geological name, but its physical and economic destiny. Can it be easily concentrated? Can it be made into high-quality sinter or pellets? Answering these questions is the foundation of a successful iron ore beneficiation project.

Your choice of beneficiation equipment must follow this logic. It is a direct consequence of your ore’s unique characteristics and the final product you intend to sell.

At ZONEDING, we are a direct manufacturer of a complete portfolio of beneficiation equipment and crushing plants. We have spent decades designing and building robust, efficient iron ore processing lines around the world. We understand that every ore body is unique. Our process starts not with a catalog, but with your metallurgical test data. Our team of engineers will design a custom flowsheet and select the right equipment to build a profitable plant based on the reality of your specific ore.

Contact us with your project data. We will deliver a professional, no-obligation technical proposal and a quote for a solution engineered for your success.

Maximize efficiency in mineral processing! Uncover performance of five key crusher types, optimized for throughput, energy, and cost-saving ore reduction.

View detailsThis article provides a clear look at the jaw crusher: its primary function, the simple yet powerful design, and why it's a staple in primary crushing stages.

View detailsThe manganese mining landscape in 2026 faces a distinct challenge: the depletion of high-grade oxide reserves. The industry focus has shifted entirely to Refractory Manganese Ore Processing. These deposits are geologically complex, often con...

View detailsTroubleshoot & resolve breakage issues in four critical ball mill parts during operation. Our guide provides solutions to keep your mill running efficiently.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy