Spodumene to Lithium Concentrate: A Complete Processing Guide

3739Explore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsSearch the whole station Crushing Equipment

The effective identification of gold ore is a systematic process based on technical analysis, not speculation. The economic viability of a potential gold deposit depends entirely on an accurate gold ore evaluation. This evaluation determines the gold ore grade, the characteristics of the host rock, and the most efficient gold ore beneficiation method. An incorrect assessment at this early stage can lead to significant financial losses.

This guide provides a structured overview of the professional methods used to identify and evaluate gold-bearing rock. We will explain how these findings directly influence the process selection and the selection of mineral processing equipment for a successful mining operation.

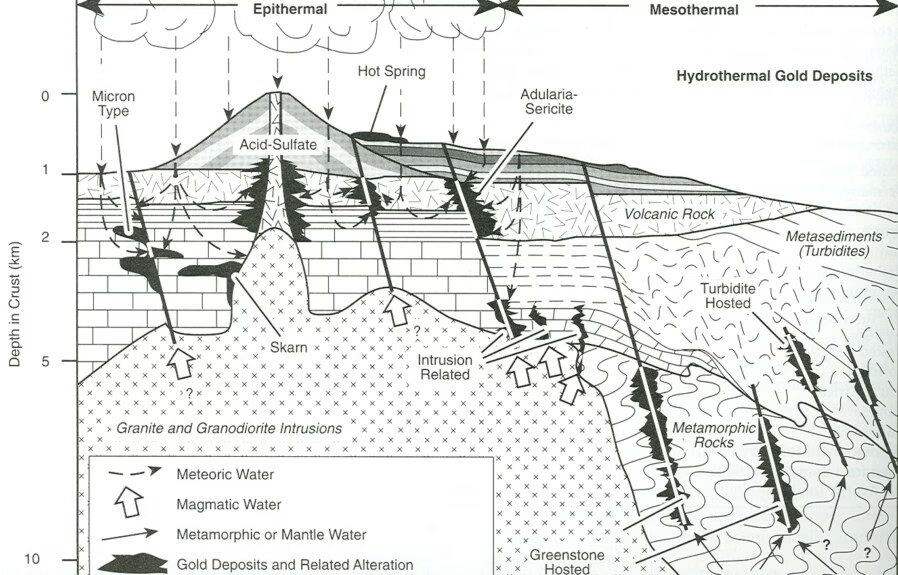

Gold is not found randomly. Its formation is tied to specific geological processes and structures. Understanding where these processes occur allows you to focus your search on the most promising areas. Prospectors look for these large-scale geological indicators to narrow their search.

1. Geological Contact Zones: These are areas where two different types of rock meet. A common and highly prospective type of contact zone is where a hot, molten igneous intrusion (like granite) has pushed its way into older surrounding rocks (like slate or schist). The intense heat and pressure at this contact can create the ideal conditions for mineral-rich fluids to deposit gold and other valuable minerals.

2. Faults and Shear Zones: Faults are large fractures in the Earth’s crust where rocks have moved past each other. These zones of broken and crushed rock act as natural “plumbing systems.” They provide open pathways for hot, hydrothermal fluids carrying dissolved gold to travel upwards from deep within the Earth. As these fluids cool or experience pressure changes within the fault zone, they can no longer hold the gold in solution, causing it to precipitate and deposit within quartz veins that fill these fractures.

3. Placer Deposits: Placer deposits are concentrations of heavy minerals, including gold, that have been eroded from their original source rock (a “lode” deposit) by natural forces like water and gravity. Over millions of years, weathering breaks down the host rock, releasing the gold. Rivers and streams then transport the gold downstream. Because gold is extremely dense, it settles out of the water current in predictable locations:

Once you have identified a promising location, the next step is to examine the rocks themselves. Gold and its common host rocks have distinct physical properties that can be used for identification in the field. This is a critical part of on-site gold ore evaluation.

1. Density (Specific Gravity): Gold is one of the densest minerals on Earth. It has a specific gravity of 19.3, meaning it is 19.3 times heavier than an equal volume of water. A piece of rock containing a significant amount of gold will feel unnaturally heavy for its size. This property is the fundamental principle behind all forms of gravity concentration equipment, from a simple gold pan to a complex spiral concentrator.

2. Color and Luster: Gold has a characteristic metallic luster and a bright, buttery yellow color. It is important to distinguish it from other yellow sulfide minerals, most commonly pyrite (“Fool’s Gold”). Pyrite has a brassy, paler yellow color and often forms cubic crystals. Gold shines in the shade, while pyrite may look dull.

3. Hardness and Malleability: This is one of the most reliable tests. Gold is a very soft metal (2.5-3 on the Mohs hardness scale). It is also highly malleable, meaning it will bend or deform under pressure without breaking. Pyrite, on the other hand, is brittle and much harder (6-6.5 on the Mohs scale). You can test a small metallic speck with the point of a steel knife or a pin:

4. Associated Minerals: Gold rarely occurs alone. It is almost always found with other specific minerals. The most common host mineral for lode gold is quartz. Look for quartz veins, especially those that are iron-stained (rusty) or have a fractured appearance. The presence of sulfide minerals like pyrite, galena, and arsenopyrite is also a positive sign that the correct mineralizing system was present.

| Property | Gold | Pyrite (“Fool’s Gold”) | How This Helps You |

|---|---|---|---|

| Color | Rich, golden yellow | Brassy, pale yellow | Gold’s color is consistent in sun or shade. |

| Streak | Golden yellow | Greenish-black | Crushing a small piece to powder reveals the true streak color. |

| Hardness | Soft (2.5-3). Can be scratched by a copper coin. | Hard (6-6.5). Cannot be scratched by steel. | Differentiates soft, valuable metal from hard, brittle sulfide. |

| Malleability | Malleable (will bend/dent) | Brittle (will shatter or crumble) | The pin test is a definitive field method to tell them apart. |

Once you have a sample of rock or sediment that you suspect contains gold, there are several simple, low-cost field methods you can use for initial detection. These methods are excellent for prospecting and confirming the presence of gold before committing to expensive laboratory analysis.

1. Gold Panning: This is the most classic and effective method for detecting placer gold or fine gold in crushed hard rock samples. The process uses water and a shallow pan to separate heavy materials from lighter sand and gravel. By swirling the material with water in the pan, the lighter particles are washed away, leaving the much denser gold particles concentrated at the bottom. The presence of even a few small flakes or “colors” in the pan is a positive confirmation.

2. Crushing and Panning: For hard rock (lode) deposits, gold is often not visible to the naked eye. To test a sample, you can crush a piece of the rock into a coarse powder. For small-scale testing, a simple hammer and steel plate can be used. For more systematic prospecting, a portable or laboratory-scale Jaw Crusher provides a more consistent product. Once the rock is crushed, the resulting material can be panned just like placer gravels to see if any fine gold can be concentrated.

3. Using a Metal Detector: A modern, high-quality metal detector is an excellent tool for prospecting, particularly for placer gold or near-surface lode deposits containing larger gold nuggets. Metal detectors work by creating an electromagnetic field and detecting disruptions caused by conductive metals. They are highly effective at locating individual pieces of gold from small pickers to large nuggets. However, they cannot detect microscopic or finely disseminated gold locked within solid rock.

These simple methods are for detection and initial confirmation only. They cannot tell you the overall gold ore grade of a deposit. If these tests yield positive results, the next mandatory step is to send representative samples to a certified laboratory for a fire assay. Only an assay can provide the quantitative data needed to assess the economic potential of a Gold Processing Plant.

Visual inspection can only identify promising rocks; it cannot quantify the amount of gold. A professional chemical assay is the only method to determine the precise gold ore grade, which is the basis for all economic calculations. The fire assay is the industry-standard method for its high accuracy.

The process involves several meticulous steps to ensure a reliable result:

An assay tells you how much gold is in the rock. An ore dressability study (also known as metallurgical testing) tells you if that gold can be profitably recovered. This study is the most critical step in de-risking a mining investment because it defines the process selection and predicts the economic outcome. It determines the optimal beneficiation flowsheet, the achievable recovery rate, and the estimated operational costs.

The central question answered by this study is whether the gold is “free-milling” or “refractory.” This classification has a profound impact on the project’s complexity and profitability.

The table below outlines the critical differences and their impact on a project’s investment profile.

| Characteristic | Free-Milling Ore | Refractory Ore | Why This Is Vital for Your Investment |

|---|---|---|---|

| Gold Occurrence | Physically separate particles | Chemically locked in sulfides | Determines if recovery is straightforward or requires advanced, costly technology. |

| Required Process | Simple: Crush -> Grind -> Gravity/Leach | Complex: Crush -> Grind -> Flotation -> Oxidation -> Leach | Refractory ore requires significantly higher capital expenditure (CAPEX) and operating expenditure (OPEX). |

| Recovery Rate | Typically high (e.g., 90-98%) | Lower and more variable; dependent on the effectiveness of the pre-treatment step. | A low recovery rate can make even a high-grade deposit unprofitable. |

| Project Risk | Lower technical and financial risk. | High technical and financial risk. Requires extensive testing and expert process design. | An investment made without this knowledge is purely speculative. |

The process selection for a Gold Processing Plant is a direct function of the ore type identified during the evaluation and testing phases. The fundamental difference between oxide and sulfide ores dictates two distinct processing routes.

Oxide ores are typically free-milling and are processed using a combination of gravity separation and cyanidation. This is a common flowsheet for a Hard Rock Gold Processing Plant.

Sulfide ores are often refractory and require a more complex Sulfide Ore Processing flowsheet to unlock the gold.

While each plant is custom-designed, a standard gold processing facility utilizes a predictable sequence of core equipment. As a manufacturer of a comprehensive range of mineral processing equipment, we at ZONEDING provide all the necessary machinery for these circuits.

Moving from a rock sample to a viable project requires expert process engineering. ZONEDING facilitates this transition by providing technical support based on actual ore characteristics. We offer a complimentary preliminary assessment to help potential miners understand their ore and the equipment required to process it.

The process is straightforward:

This no-obligation service provides you with the critical initial data needed to make informed investment decisions. Contact us today to begin your gold ore evaluation.

Explore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsDiscover critical factors in steel ball configuration impacting your gold ball mill's performance. Improve grind size, throughput, and energy efficiency today.

View detailsDiscover the main types of antimony ore, like stibnite, and learn the key ore dressing methods used for extraction, including flotation and gravity separation.

View detailsYour ultimate guide to choosing a hard rock gold processing solution. Learn about key factors like ore type, capacity, and processing methods (CIL, flotation) to make the right choice.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy