Search the whole station Crushing Equipment

This setup is sulfide rock minerals processing plant, suitable for processing Sulfide rock Gold, Copper, Silver, Zinc, Lead, Fluorite ore, etc.

Has a high recovery ratio for sulfide-type minerals. Usually can reach about 85-90% depending on material conditions. ZONEDING provides sulfide ore processing plant and equipment to max your profit.

You are likely facing the challenge of extracting valuable metals from complex sulfide ores. Sulfide ore processing is a specialized field. It combines various techniques to liberate and concentrate metals like copper, lead, zinc, gold, and silver. ZONEDING can understand that successful sulfide ore metallurgy depends on tailored solutions, from initial to final concentrate. This guide will walk you through the critical aspects of transforming these challenging ores into valuable products, helping you make informed decisions for your project.

Last Updated: March 2025 | Estimated Reading Time: 25 minutes

Sulfide ores are naturally occurring minerals where metals are chemically bonded with sulfur. These ores, like chalcopyrite (copper), galena (lead), sphalerite (zinc), and pyrite (iron sulfide often associated with gold), are primary sources for many base and precious metals. Processing them, however, presents unique challenges. The value often lies in complex intergrowths of multiple sulfide minerals and gangue (waste rock). This complexity demands sophisticated mineral processing equipment and a deep understanding of mineralogy. You need to separate these valuable minerals not only from gangue but also from each other, which can be tricky if their properties are similar.

A major challenge in sulfide ore processing is the tendency of sulfide minerals to oxidize. This oxidation can occur rapidly once the ore is mined and exposed to air and water. This “weathering” changes the surface properties of the minerals. It can severely hinder the effectiveness of downstream processes, especially sulfide ore flotation. Another significant issue is managing by-product and deleterious elements. Some sulfide ores contain valuable by-products like gold, silver, or indium. Others contain harmful elements like arsenic, mercury, or antimony. These can impact the concentrate’s marketability or require special handling, adding to the complexity of the beneficiation process flow. The presence of certain gangue minerals can also interfere with processing, consuming reagents or contaminating the final product. These factors make each sulfide ore deposit unique, requiring a customized metallurgical approach.

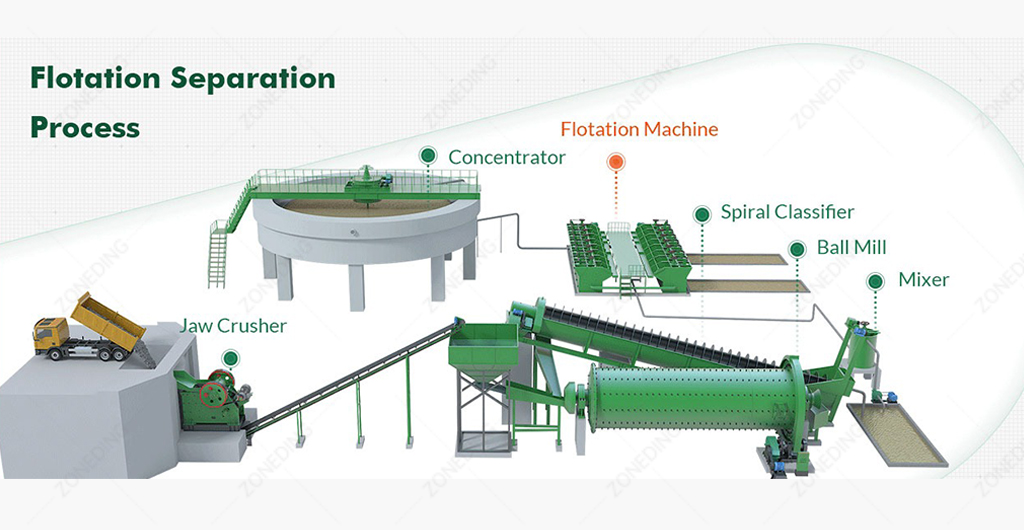

The typical beneficiation process flow for sulfide ores involves several critical stages, each aiming to progressively liberate and concentrate the valuable minerals. Your journey usually starts with comminution, which is size reduction. This includes sulfide ore crushing using equipment like Jaw Crushers and Cone Crushers to break down large run-of-mine ore into smaller, manageable pieces. Following crushing, sulfide ore grinding, often using Ball Mills or Rod Mills, further reduces the particle size. The goal of grinding is to achieve liberation – freeing the individual valuable mineral particles from the gangue and from each other.

Achieving the right degree of liberation without overgrinding is a delicate balance in sulfide ore processing. Overgrinding creates excessive fine particles (slimes). These slimes can cause problems in flotation, increase reagent consumption, and make solid-liquid separation difficult. ZONEDING emphasized the importance of “effective liberation.” This means focusing on liberating the target minerals sufficiently for economic recovery, rather than blindly grinding everything to ultra-fine sizes. Stage grinding with inter-stage screening or classification, perhaps using a Spiral Classifier or Hydrocyclones, can help optimize this. Another crucial, often underestimated aspect is “ore freshness.” Sulfide minerals oxidize quickly. This oxidation starts the moment the ore is extracted. The “oxidation countdown” means that the time between mining and flotation should be minimized. ZONEDING teams advise planning for “just-in-time” processing where possible. If stockpiling is unavoidable, consider measures to reduce oxidation, as this is often more cost-effective than trying to fix oxidized ore in the flotation circuit. After grinding, the ore slurry typically proceeds to separation stages like flotation, which will discuss next.

Sulfide ore flotation is the most widely used and economically important method for concentrating sulfide minerals like copper, lead, zinc, and gold-bearing sulfides. This process exploits differences in the surface hydrophobicity (water-repelling nature) of various minerals. In a typical Flotation Machine, finely ground ore is mixed with water to form a slurry. Specific chemicals called flotation reagents are added. Collectors make the target sulfide minerals hydrophobic. Frothers help create stable air bubbles. Modifiers (activators, depressants, pH regulators) enhance the selectivity of the separation. Air is then introduced into the slurry. The hydrophobic sulfide mineral particles attach to the air bubbles and rise to the surface, forming a froth. This froth, rich in valuable minerals, is skimmed off. The hydrophilic gangue minerals remain in the slurry and are discharged as tailings.

The success of sulfide ore flotation depends heavily on careful control of various parameters. These include particle size, slurry density, pH, reagent dosages, aeration rate, and froth characteristics. For complex ores containing multiple sulfide minerals (e.g., copper ore beneficiation from an ore also containing lead and zinc), sequential flotation is often employed. This involves floating one mineral type first while depressing others, then re-conditioning the tailings to float the next mineral. A critical, yet often overlooked, parameter is the electrochemical potential (Eh or ORP) of the pulp. Different collectors and sulfide minerals have optimal “Eh windows” for effective interaction. By carefully controlling the Eh, sometimes with oxidizing or reducing agents, you can selectively alter mineral surfaces. This significantly improves separation efficiency, especially in tricky multi-metal systems. ZONEDING advised our clients to consider Eh monitoring and control as a key part of their flotation strategy, not just relying on pH and reagent levels.

Choosing and optimizing the flotation reagent scheme is crucial for achieving high recovery and grade in sulfide ore flotation. There is no one-size-fits-all solution; the reagent suite must be tailored to the specific mineralogy of your ore. The main types of flotation reagents include collectors, frothers, and modifiers. Collectors, such as xanthates, dithiophosphates (DTPs or “black gold”), or mercaptobenzothiazoles (MBTs), are organic chemicals that selectively adsorb onto the surface of sulfide minerals, rendering them hydrophobic. The choice of collector depends on the target mineral. For example, xanthates are widely used for many sulfides, while DTPs might be better for certain copper or gold-bearing sulfides.

Modifiers play a vital role in selective flotation. pH regulators like lime (CaO) or soda ash (Na₂CO₃) are used to adjust the pulp pH, which affects the surface charge of minerals and the effectiveness of collectors. Depressants, such as sodium cyanide (for pyrite and some zinc sulfides), sodium metabisulfite (for sphalerite), or organic polymers (like CMC for talc), are used to prevent unwanted minerals from floating. Activators, like copper sulfate for activating sphalerite, are used to enhance the floatability of specific minerals. The interaction between these reagents and the minerals, as well as with each other, is complex. You also need to consider the impact of gangue minerals. Some gangue, like talc or graphite, are naturally floatable and can contaminate your concentrate. Others, like certain clays or carbonates, can consume reagents or slime mineral surfaces. ZONEDING emphasizes the importance of detailed mineralogical analysis, including gangue characterization, to develop an effective reagent strategy. Careful laboratory testing and pilot plant trials are essential to optimize dosages and combinations for your specific sulfide ore processing needs.

Hydrometallurgy, which involves aqueous chemical processing, offers alternative or complementary routes for extracting metals from certain sulfide ores or their concentrates. While flotation is dominant for initial concentration, leaching technology can be very effective for specific scenarios. Leaching is the process of dissolving valuable metals from an ore or concentrate using a liquid solvent (lixiviant). For sulfide ores, common leaching methods include acid leaching (e.g., with sulfuric acid, often aided by bacteria in bioleaching for low-grade copper sulfides), cyanide leaching (primarily for gold and silver), or chloride/sulfate leaching under pressure for more refractory sulfides.

Hydrometallurgy can be particularly advantageous for low-grade ores where flotation might be uneconomical, or for complex concentrates that are difficult to treat by conventional smelting (pyrometallurgy). For example, heap leaching is a low-cost hydrometallurgical technique used for extracting copper from low-grade oxide and secondary sulfide ores. Bioleaching, using microorganisms to catalyze the oxidation and dissolution of sulfide minerals, is an environmentally friendlier option for some copper and gold ores. After leaching, the metal-rich solution (pregnant leach solution or PLS) undergoes further processing steps like solvent extraction (SX) and electrowinning (EW) to recover the pure metal. While hydrometallurgy can offer benefits like higher selectivity and the ability to treat complex materials, it also has challenges. These include managing leach solution chemistry, handling potentially hazardous reagents like cyanide, and dealing with solid residues. The choice between hydrometallurgy and other routes depends on ore mineralogy, grade, scale of operation, and economic factors.

Pyrometallurgy, involving high-temperature processes, is the traditional and still dominant method for treating sulfide mineral concentrates to produce metals. After flotation, the sulfide concentrates (e.g., copper, lead, or zinc concentrates) are typically dewatered and then subjected to pyrometallurgical operations like roasting, smelting, and converting. Roasting involves heating the concentrate in the presence of air to remove some sulfur as sulfur dioxide (SO₂) and convert metal sulfides to oxides or sulfates, making them more amenable to smelting. Smelting is a melting process where the roasted or unroasted concentrate is heated to high temperatures with fluxes (like silica or limestone) in a furnace (e.g., flash furnace, reverberatory furnace, or electric furnace). This separates the valuable metal from impurities, forming a molten metal sulfide phase (matte) and a molten silicate waste phase (slag).

Converting further purifies the matte by blowing air or oxygen through it, oxidizing remaining iron and sulfur. For example, in copper smelting, this produces blister copper. A major challenge in pyrometallurgy of sulfide concentrates is the generation of large volumes of sulfur dioxide (SO₂) gas. SO₂ is a significant air pollutant and a precursor to acid rain. Modern smelters are required to capture this SO₂. It is typically converted into sulfuric acid, which can be sold or used, thus mitigating environmental impact and sometimes adding economic value. However, SO₂ capture and acid plant operation add to the capital and operating costs of smelters. Other environmental concerns include dust emissions and slag disposal. Despite these challenges, pyrometallurgy remains highly efficient for large-scale metal production from high-grade sulfide concentrates. The choice of smelting technology and the design of environmental controls are critical for sustainable pyrometallurgical operations.

Refractory sulfide ores are those that are difficult to treat by conventional sulfide ore processing methods, resulting in low metal recoveries or high reagent consumption. Your ore might be considered refractory due to several reasons. One common issue is very fine-grained dissemination of valuable minerals, meaning the gold, copper, or other target metals are locked within other minerals at a microscopic scale. This requires extremely fine sulfide ore grinding to achieve liberation, which can be costly and lead to slime-related problems in flotation. Another type is carbonaceous ores, where naturally occurring carbonaceous material (like graphite or organic carbon) can adsorb dissolved gold (preg-robbing in gold leaching) or non-selectively float with sulfide minerals, contaminating the concentrate.

Arsenical sulfide ores, particularly those containing arsenopyrite or enargite, pose another challenge. Arsenic is a deleterious element that can cause environmental problems and penalties from smelters. The valuable metals might also be locked within the arsenical mineral’s crystal lattice, making them inaccessible to lixiviants or flotation collectors. Treating refractory sulfide ore often requires specialized pre-treatment steps before cyanidation (for gold) or flotation. These can include ultra-fine grinding, roasting (to oxidize sulfides and carbon), pressure oxidation (POX), or bio-oxidation. Each method has its pros and cons regarding cost, effectiveness, and environmental impact. For instance, roasting can liberate locked gold but generates SO₂. POX and bio-oxidation are hydrometallurgical alternatives that can break down sulfide matrices at lower temperatures without direct SO₂ emissions, but they require specialized equipment and careful control. Successfully processing refractory sulfide ore demands a thorough understanding of its specific refractory characteristics, often identified through advanced mineralogical studies.

Sustainable sulfide ore processing requires minimizing environmental impact while ensuring economic viability and social responsibility. The nature of sulfide ores, particularly their sulfur content, presents specific environmental challenges. One of the most significant is Acid Mine Drainage (AMD), also known as acid rock drainage (ARD). AMD occurs when sulfide minerals, especially pyrite (FeS₂), are exposed to air and water, leading to oxidation and the generation of acidic water rich in dissolved heavy metals. This acidic water can contaminate surface and groundwater resources if not properly managed. Effective AMD prevention and treatment strategies are crucial. These include minimizing water and oxygen ingress into waste rock piles and tailings, segregating potentially acid-generating materials, and implementing water treatment systems.

Tailings management is another critical aspect of sustainable sulfide ore processing. Tailings are the fine-grained waste material left over after valuable minerals have been extracted. Sulfide tailings can be a long-term source of AMD. Modern tailings management practices focus on secure containment in engineered tailings storage facilities (TSFs), dewatering tailings (e.g., to paste or filtered tailings) to reduce water content and improve stability, and implementing cover systems to limit oxidation. ZONEDING believes in a life-cycle approach to tailings. This means considering tailings not just as a waste but as a potential future resource or a material requiring long-term geochemical management. Exploring options like reprocessing tailings for residual values, using them for backfill, or designing for closure from the outset are key components. Water conservation through recycling process water and minimizing fresh water intake are also essential for sustainability. Adopting best practices in environmental management is not just about compliance; it’s about ensuring the long-term viability of your mining operation.

Several economic factors significantly influence the feasibility and profitability of a sulfide ore processing project. These go beyond just the prevailing metal prices. The ore grade (concentration of valuable metal) is fundamental; higher grades generally mean lower processing costs per unit of metal produced. The mineralogy of the ore is equally important. Complex mineralogy, fine dissemination, or the presence of refractory components can substantially increase both capital expenditure (CAPEX) for specialized mineral processing equipment and operating expenditure (OPEX) due to higher energy and reagent consumption or lower recoveries. The scale of the operation also plays a major role; larger operations can benefit from economies of scale, but also require larger initial investments.

Another critical economic consideration is the presence and deportment of by-product and deleterious elements. Valuable by-products (e.g., gold, silver, molybdenum in a copper ore) can significantly enhance project economics. Conversely, deleterious elements (e.g., arsenic, mercury, bismuth) can incur penalties from smelters or require costly removal processes. Understanding how these elements behave throughout your beneficiation process flow and where they report is vital. You need to manage this “value chain” from ore to final product. Infrastructure availability (power, water, transportation), location (affecting logistics and labor costs), regulatory requirements (environmental permits, taxes, royalties), and metallurgical recovery rates are also key drivers of profitability. A comprehensive techno-economic evaluation, considering all these factors, is essential before committing to a sulfide ore processing project.

Choosing the best sulfide ore processing plan and equipment combination for your project requires a tailored approach based on detailed ore characterization, metallurgical test work, and economic evaluation. There is no universal “best” solution. Your primary goal is to select a beneficiation process flow and mineral processing equipment that maximizes economic returns while meeting environmental and social obligations. The process starts with understanding your ore: its mineralogy, grade, liberation characteristics, hardness, and the presence of any refractory components or problematic gangue minerals. Extensive laboratory and pilot-scale testing are indispensable to determine the optimal processing route. This might involve comparing different grinding strategies, flotation reagent schemes, or even evaluating hydrometallurgical versus pyrometallurgical options for concentrate treatment.

When selecting equipment, factors like capacity, efficiency, reliability, wear life, and supplier support are crucial. For sulfide ore crushing, you might consider Jaw Crushers for primary crushing, followed by Cone Crushers or Impact Crushers for secondary and tertiary stages. For grinding, Ball Mills are common, but SAG mills or HPGRs might be better for certain applications. Flotation Machines come in various designs (e.g., mechanically agitated cells, columns). The choice depends on particle size, aeration requirements, and selectivity needs.ZONEDING leverages our experience to help you select and integrate equipment that forms an efficient and robust processing circuit. ZONEDING emphasizes considering the entire flowsheet, from run-of-mine to final product, ensuring each unit operation complements the others. Partnering with experienced engineers and equipment suppliers who understand the nuances of sulfide ore metallurgy is key to developing a successful and profitable operation.

Question 1: What is the most common method for concentrating copper sulfide ores?

Sulfide ore flotation is by far the most common and economically significant method for copper ore beneficiation from sulfide ores like chalcopyrite and bornite. It selectively separates copper sulfide minerals from gangue and other sulfides.

Question 2: How does ore oxidation affect sulfide ore flotation?

Ore oxidation changes the surface chemistry of sulfide minerals, making them less responsive to flotation collectors. This can lead to significantly lower mineral recovery and/or poor concentrate grade. Minimizing ore exposure time before flotation is crucial.

Question 3: Are there alternatives to smelting for lead-zinc sulfide concentrates?

Yes, while pyrometallurgy (smelting) is common, hydrometallurgy options exist for lead-zinc ore beneficiation concentrates. These include various leaching technologies, though they can be complex and depend on specific concentrate characteristics and economics.

Question 4: What makes a gold-bearing sulfide ore “refractory”?

A gold-bearing sulfide ore is often refractory if the gold is sub-microscopically disseminated within sulfide minerals (like pyrite or arsenopyrite), or if carbonaceous material in the ore adsorbs dissolved gold (preg-robbing). These require pre-treatment like roasting or oxidation before gold can be efficiently recovered by cyanidation.

Successfully processing sulfide ores is a complex but achievable endeavor. It demands a deep understanding of your ore’s unique characteristics and a carefully designed beneficiation process flow. Key techniques include sulfide ore crushing, sulfide ore grinding, and particularly sulfide ore flotation, often complemented by hydrometallurgy or pyrometallurgy for concentrate treatment. Managing challenges like ore oxidation, refractory components, deleterious elements, and environmental aspects like acid mine drainage and tailings management is critical. Your choice of mineral processing equipment must align with these technical requirements and your project’s economic goals.

If you are embarking on a sulfide ore processing project, the essential first step is comprehensive metallurgical testing. This will provide the foundation for selecting the optimal processing route and equipment. ZONEDING is committed to providing robust and efficient solutions tailored to your specific needs.

ZONEDING is your trusted global partner for a comprehensive range of mineral processing equipment and solutions, specializing in sulfide ore processing. With extensive experience and a commitment to innovation, we provide equipment for sulfide ore crushing, grinding (including Ball Mills and Rod Mills), Flotation Machines, thickening, and more. ZONEDING can assist clients worldwide, from initial flowsheet design and equipment selection to installation, commissioning, and after-sales support. Our goal is to help you maximize your recovery and profitability while adhering to sustainable practices.

Contact ZONEDING’s experts today to discuss your sulfide ore project and discover how our tailored solutions can bring your vision to life!

Last Updated: March 2025