Search the whole station Crushing Equipment

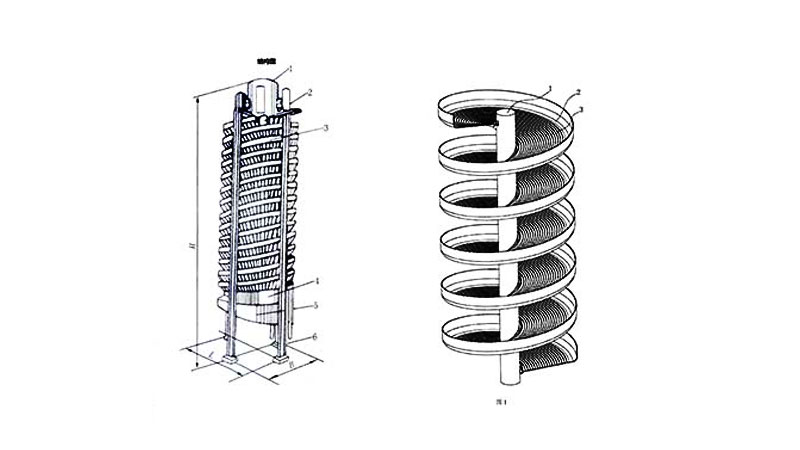

Brief Introduction: Spiral chute, which is also known as spiral chute separator, is a kind of gravity separation equipment.

Spiral gravity separator spiral chute is also called spiral concentrator or gravity separator, it’s a kind of gravity concentrator.

Spirals are made of high-density fiberglass, high quality emery and unsaturated resin.

A spiral chute is essentially a sloping, spiral-shaped channel designed to separate minerals of different densities.

It uses gravity and centrifugal force to achieve this separation. The spiral design allows for a continuous flow of slurry (a mixture of water and minerals) as it moves down the chute.

Spiral chutes are widely used in the mineral processing industry because they are relatively inexpensive to operate and maintain.

The simple design means fewer moving parts and reduced energy consumption, lowering the overall operational costs.

The main goal of a spiral chute is beneficiation, which means concentrating valuable heavy minerals from a raw ore stream and discarding the lighter, less valuable waste material (known as gangue).

Spiral chutes advantages are obvious.

For operations looking to balance cost-effectiveness, ease of use, and environmental responsibility, a spiral chute is a compelling choice. ZONEDING MACHINE’s spiral chutes are engineered for durability and consistent performance, ensuring long-term benefits for your mineral processing needs.

Spiral chutes are versatile and find applications in various sectors of mineral processing. These include:

It can also used in Rutile, ilmenite and zircon concentration; Iron ore, chromite and manganese beneficiation; Tin, tantalum and ore concentration; Gold, native copper and base metal recovery; Silica sands processing; Titano-magnetite concentration.

The ability to handle large volumes of material efficiently makes spiral chutes ideal for a wide range of mining and mineral processing operations.

Spiral chutes are particularly effective for recovering a variety of minerals that have significant density differences. These commonly include:

The spiral chute is suitable for separation of 0.3-0.02mm fine materials such as iron ore, ilmenite ore, chromite ore, pyrite ore, zircon ore, rutile ore, monazite ore, tungsten ore, tin ore, tantalum ore, niobium ore and other materials with enough specific gravity difference. It is the best roughing gravity equipment, which has been widely used in ferrous and nonferrous metal mines.

The key is that the valuable minerals need to be significantly denser than the waste material (gangue). This density difference allows for effective separation as the slurry flows through the spiral. ZONEDING MACHINE can customize spiral concentrators to optimize recovery for your specific mineral types, ensuring you get the best possible results.

Spiral chutes typically operate effectively within a specific particle size range. The optimal range is usually between 0.15 mm and 3 mm. Accurate feed preparation is critical for achieving optimal separation.

If the feed contains particles outside this range, the separation efficiency can be significantly reduced. To address this, consider using screens or hydrocyclones to classify the feed before it enters the spiral chute. This pre-treatment step will ensure that the material entering the chute is within the optimal size range, improving overall performance.

A spiral chute consists of several key components that work together to achieve separation. These include:

The spiral channel is typically constructed from materials like fiberglass, polyurethane, or stainless steel, depending on the application and the abrasiveness of the material being processed.

The spiral chute parts have a distributor and feed chute in the upper part and a product interceptor and collection chute in the lower part. The entire equipment is framed vertically with steel frames.

The spiral chute utilizes a combination of gravity and centrifugal force to separate minerals. The process begins with the introduction of a slurry of water and minerals into the spiral channel. As the slurry flows downwards, gravity causes the denser particles to settle towards the bottom of the channel.

Simultaneously, centrifugal force pushes these heavier particles towards the inner side of the spiral. The lighter particles, on the other hand, remain on the outer side. As the slurry progresses down the spiral, adjustable product splitters are strategically positioned to separate the different streams based on their density. The concentrate (valuable minerals), middlings (a mixture of valuable and waste), and tailings (waste material) are then collected in separate collection launders.

Gravity is the primary driving force behind the separation process in a spiral chute. Heavier minerals are more strongly influenced by gravity and therefore settle faster and are drawn towards the inner side of the spiral.

This interaction between gravity and centrifugal force creates a differential movement of particles based on their density, enabling the separation of valuable minerals from waste material. The design of the spiral channel optimizes this gravitational effect to maximize separation efficiency.

| Model | Processing capacity(t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

The price of a spiral chute can vary depending on factors such as size, capacity, and materials of construction. However, compared to other mineral separation technologies, spiral chutes are generally a cost-effective option.

Spiral Chutes Price Range is from USD1500-USD 4000 per set according to your capacity and requirements. ZONEDING MACHINE can also provide Customization for you according to your material, capacity, and land requirements.

The relatively low capital investment, combined with the low operating costs, often results in a favorable return on investment (ROI). The exact ROI will depend on the specific application, the value of the recovered minerals, and the operating parameters. Contact ZONEDING MACHINE for a tailored quote that considers your specific needs and operational context.

Selecting the right spiral chute for your application requires careful consideration of several factors. These include:

Consulting with a mineral processing expert can help you determine the optimal spiral chute configuration for your specific requirements. ZONEDING MACHINE’s experts are available to assist you in selecting the right equipment for your unique needs.

Proper installation is essential for ensuring optimal performance of your spiral chute.

Here’s a general outline:

Regular maintenance is critical for extending the life and maintaining the performance of your spiral chute. Key maintenance tasks include:

ZONEDING MACHINE provides manuals and instructions , offers training on your workers. And we can give quick respond if you have any questions on our spiral chutes machine. ZONEDING MACHINE is reliable supplier for you.

Spiral chutes and shaking tables are both gravity concentration devices, but they are best suited for different applications. Spiral chutes excel at handling large volumes of material with relatively coarse particles. Shaking tables are more effective for finer particles and achieving a higher degree of separation.

The choice between the two depends on the specific characteristics of your material and the desired outcome of the separation process.

Low spiral chute efficiency can be attributed to several factors. These include:

Troubleshooting these potential issues can help restore your spiral chute to optimal performance.

The demand for spiral chutes remains strong, particularly in regions with significant mining activity. The focus is on maximizing recovery, minimizing environmental impact, and reducing operating costs.

ZONEDING MACHINE has a proven track record of successful spiral chute installations worldwide. For instance, a tin mine in Malaysia experienced a 15% increase in tin recovery after implementing ZONEDING MACHINE’s spiral chute solution. This demonstrates the tangible benefits of our equipment and expertise.

ZONEDING MACHINE has over 30 years of experience in manufacturing high-quality mineral processing equipment. We offer a comprehensive range of spiral chutes designed for various applications. Our chutes are known for their durability, efficiency, and low maintenance requirements. We also can share the spiral concentrator knowledge with you.

Contact ZONEDING MACHINE today to discover how our spiral chute solutions can optimize your mineral processing operation and increase your profitability.

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy