What Is a Secondary Impact Crusher? Principle & Benefits

3942Explore secondary impact crushers for efficient material reduction. They produce cubical, well-shaped aggregate, ideal for construction, road building.

View detailsSearch the whole station Crushing Equipment

You have a dolomite resource. But the path from a mountain of rock to a profitable product, whether it’s construction sand or industrial powder, is paved with critical engineering decisions. The biggest mistake is treating crushing and grinding as separate problems. They are one system, and optimizing the connection between them is the secret to lowering your cost per ton.

A complete dolomite production line is an integrated system that uses a multi-stage crushing process to efficiently reduce rock size, followed by a specific dolomite grinding equipment to produce the final powder or sand product. The key to low operating cost is to use cheaper crushing to create the finest possible feed for the energy-intensive grinding stage.

This guide will walk you through the design of a complete dolomite processing plant, showing you how the right equipment choices at each stage can dramatically reduce your operating expenses.

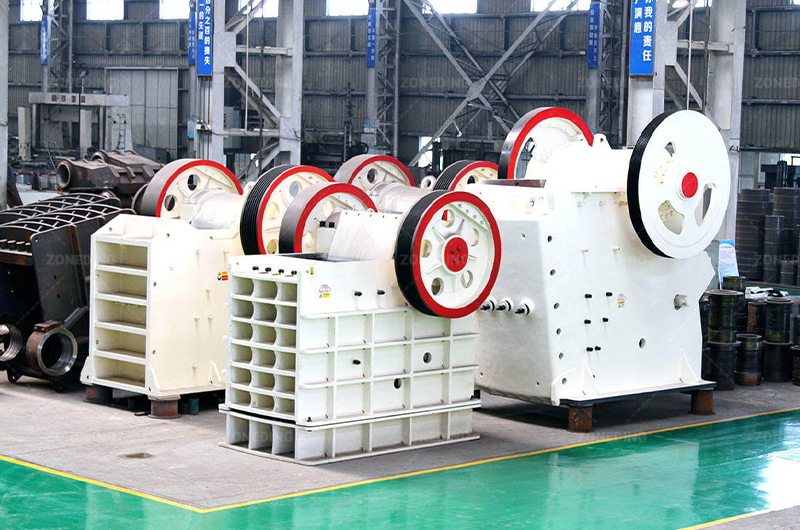

The crushing stage does the heavy lifting, taking large, stubborn rocks and breaking them down.

Dolomite crushing equipment includes primary crushers like jaw crushers for initial size reduction, secondary crushers like impact crushers or cone crushers for further reduction, and tertiary crushers like sand making machines to shape the final product.

The goal of this stage is to prepare the material for the next step as efficiently as possible.

Many operators get this wrong. They see the crushing circuit’s only job as size reduction. This is a limited view.

A well-designed dolomite crushing process is built on the principle of “more crushing, less grinding.” It aims to produce the smallest and most consistent feed size for the grinding mill. Because crushing is mechanically more efficient and cheaper per ton than grinding, this strategy significantly lowers the plant’s overall energy consumption and operating cost.

Think of it this way: every millimeter you reduce the stone size in the crushing stage saves you significant money in the grinding stage. The grinding mill is the most power-hungry machine in your entire plant. If you feed it 30mm stone instead of 50mm stone, its throughput will increase, and its power draw per ton will decrease. A three-stage crushing circuit (jaw crusher -> cone crusher -> fine crusher) that produces a <20mm feed for your mill will be far more profitable than a simpler two-stage circuit that feeds the mill with larger material.

This is the most critical decision in your crushing circuit, and the answer depends entirely on your final product.

For producing mill feed for a grinding plant, a cone crusher is superior because it uses compression and generates fewer fines. For producing high-quality cubical construction aggregate, an impact crusher is better because it shatters the rock, but at the cost of much higher wear parts consumption.

Dolomite can be quite abrasive. An impact crusher will produce beautiful, cube-shaped sand and aggregates, but you will be replacing blow bars frequently, which is a major operating expense. A cone crusher squeezes the rock, which is a more energy-efficient process that is kinder on wear parts. It produces fewer unwanted fines (dust), making it the ideal choice for preparing feed for a grinding mill where fines are controlled by the mill’s classifier.

| Feature | Cone Crusher | Impact Crusher |

|---|---|---|

| Crushing Action | Squeezing / Compression | High-Speed Impact / Shattering |

| Product Shape | Angular, Flaky | Highly Cubical |

| Fines Generation | Lower | Higher |

| Wear Part Cost | Lower | Higher (especially with abrasive dolomite) |

| Best For | Mill Feed, Road Base | High-Spec Concrete Sand, Asphalt Aggregate |

If your goal is to produce high-quality manufactured sand, your crushing circuit needs a specialized final stage.

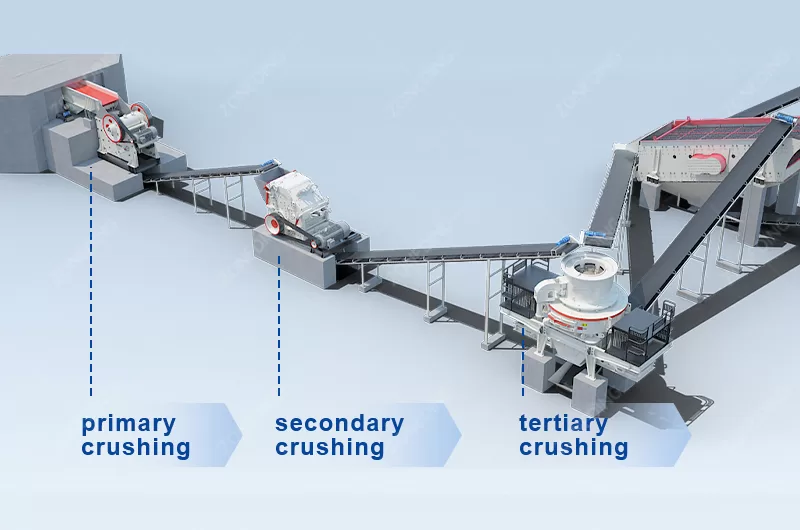

A dedicated sand production line must include a VSI crusher (Sand Making Machine) as the final crushing stage. The VSI uses a high-speed rotor to throw stones against an anvil ring, a process called “rock-on-rock” crushing. This shapes the particles, removing sharp edges and creating a cubical shape that is ideal for concrete.

A typical stone crushing plant for sand would look like this: Jaw Crusher (Primary) -> Cone Crusher or Impact Crusher (Secondary) -> Vibrating Screen -> Sand Making Machine (Tertiary Shaping). The vibrating screen is critical. It sends correctly sized material to the finished product piles and routes any oversized material back to the VSI for another pass. This closed-circuit ensures a consistent, high-quality product. A sand washing machine may be added to remove excess fine powder.

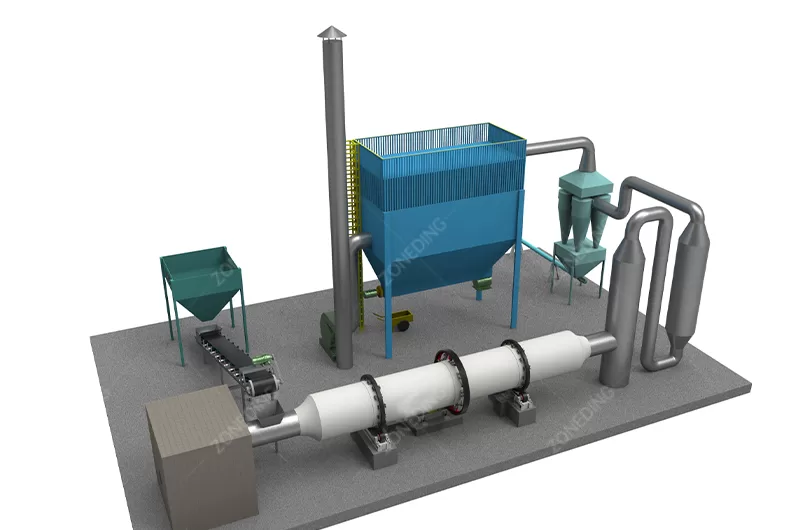

The grinding stage is where you create high-value industrial powders.

Dolomite grinding equipment, also known as grinding mills or pulverizers, are machines designed to grind crushed dolomite into fine or ultrafine powders. Common types include Raymond mills for general-purpose powders (100-400 mesh) and vertical roller mills for high-volume, fine powder production (400-1250 mesh).

The choice of mill determines the fineness, capacity, and profitability of your powder products.

The difference between selling low-grade agricultural powder and high-grade filler for paints is determined entirely by your grinding mill’s capability.

The type of dolomite grinding equipment you choose dictates the fineness (mesh size) and particle size distribution of your final dolomite powder. A basic Raymond mill is cost-effective for coarse powders (e.g., 200 mesh). But to enter the lucrative fine and ultrafine markets (e.g., 800 mesh), a more advanced vertical roller mill is necessary.

Different industries have strict specifications. The agricultural market might only need a coarse 100-mesh powder. The paint and plastics industries, however, demand highly consistent, ultrafine powders of 800 mesh or even finer. A plant equipped with a high-performance mill can produce these premium products and command a much higher price per ton. Your mill choice is a direct investment in your product’s value.

If your business plan involves selling high-value powders, the Raymond mill has limitations. The vertical roller mill (VRM) is the modern standard for this application.

A vertical roller mill offers three key advantages for producing fine dolomite powder: 1) Energy Efficiency, consuming 30-50% less power than a ball mill system; 2) Integrated Grinding, Drying, and Classifying in one unit, saving space and investment; and 3) Precise Particle Size Control with an integrated dynamic classifier, essential for producing high-spec ultrafine powders.

The integrated classifier is the VRM’s secret weapon. It allows you to adjust the final product fineness with high precision simply by changing the rotor speed. This gives you the flexibility to produce different grades of powder for different customers from a single machine. While the initial project investment for a VRM is higher than for a Raymond mill, its lower energy consumption and ability to produce premium products provide a much faster return on investment for serious producers.

Seeing the whole picture helps to understand how each piece of equipment fits together.

A complete dolomite processing plant begins with a vibrating feeder supplying a jaw crusher. The crushed material is screened, with oversized rock sent to a cone crusher. The final crushed product is stored in a bin before being fed into the grinding equipment. The finished powder is then pneumatically conveyed to a product silo for storage and packaging.

Every component is crucial. A feeder that is too small will starve the crusher. A conveyor belt that is too narrow will become a bottleneck. A poorly selected screen will reduce the efficiency of the entire circuit. That is why working with an experienced supplier like ZONEDING is vital. We don’t just sell individual machines; we design and supply complete, balanced, and efficient stone crushing plants where every component works in harmony.

A successful dolomite production line is an optimized system, not just a collection of machines. By focusing on the synergy between the crushing process and the grinding equipment, you can design a plant that minimizes energy consumption and maximizes product value, directly leading to a lower cost per ton and higher profitability.

Explore secondary impact crushers for efficient material reduction. They produce cubical, well-shaped aggregate, ideal for construction, road building.

View detailsCopper sulfide flotation is a standard mineral processing method. However, different ore bodies require specific processing strategies due to variations in mineral composition. As high-grade deposits deplete, the industry now processes more compl...

View detailsHow much does a basalt crushing plant cost? This guide breaks down the price of all machines, explains the process, and helps you budget for a profitable plant.

View detailsThe feeding assembly regulates the input rate of ore, water, and circulating load into the grinding chamber. Efficiency in ball mill operation depends on the compatibility between the feeding device and the process flow requirements. An incorrect...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy