What are effective ways to boost ball mill output/capacity?

3819Guide to improving ball mill output. Learn about optimizing grinding media, feed, speed, and liners to achieve maximum productivity and efficiency.

View detailsSearch the whole station Crushing Equipment

Fluorite is a vital mineral. It is used in many industries. It goes into metallurgy, chemicals, and ceramics. Transforming raw fluorite ore into a high-grade concentrate needs the right equipment. This is a complex task. I have spent many years helping clients build efficient fluorite beneficiation equipment lines. I have seen how the right equipment makes all the difference. This guide will help you choose wisely. It covers every step. It goes from raw ore to finished concentrate. You want to maximize your fluorite’s value. This means selecting machines that fit your specific needs. Let’s make sure your project succeeds.

Choosing the correct fluorite beneficiation equipment forms your project’s foundation. It determines your profitability. It affects your product’s quality. It also impacts operating costs. I have seen projects succeed or fail. The first equipment choice often explains the outcome.

Incorrect selection creates many problems. You might face low recovery. Energy use could be high. Meeting product specs might be difficult. This wastes money. It also increases maintenance needs. A smart selection leads to smooth operation. It brings high efficiency. It ensures consistent, high-grade product. This makes your investment valuable. Selecting the right fluorite equipment is crucial for long-term success.

Before selecting machines, understand your project deeply. This means a full fluorite ore characteristics analysis. It also means clear product goals. These are the most critical factors for your fluorite processing equipment decisions. Ignoring them leads to big problems. My experience shows this initial analysis is the most crucial step. It avoids costly mistakes later.

The process begins with your raw material. It includes what you want to sell. Your budget, and environmental rules also factor in. These points together form your equipment strategy. Skipping any step can lead to a poor setup. It can lower plant efficiency. It might even cause project failure. Let’s explore these key areas. This will start you on the right path for effective fluorite beneficiation equipment.

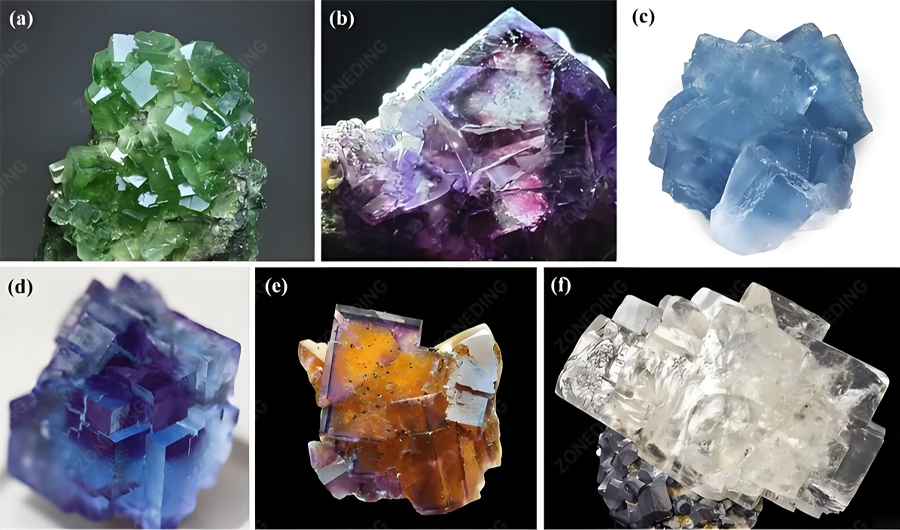

Your ore’s specific minerals are crucial. They define how you process it. Fluorite ore characteristics analysis must identify all minerals. This includes fluorite (CaF2). It also includes associated gangue minerals. Common ones are calcite (CaCO3), quartz (SiO2), barite (BaSO4), and sulfides. Understanding them guides your entire fluorite beneficiation process.

Your desired final product drives your process flow. It shapes your fluorite processing equipment configuration. Different industries require different fluorite qualities. This means varying levels of fineness and purity. You must define these clearly. This sets strict demands for your equipment.

Your target production capacity sets the size of your fluorite beneficiation equipment. This is a major investment factor. Balancing equipment scale with your budget is crucial. You want optimal throughput without overspending.

Environmental rules are getting stricter. Your fluorite processing equipment must meet these standards. This is not just about avoiding fines. It is about sustainable operation. It protects your brand image. Modern fluorite beneficiation equipment must consider the environment from the start.

After understanding your ore and product goals, you map your fluorite beneficiation process. This involves a sequence of steps. Each step has specific mineral processing equipment. This section details the core machinery. It supports each stage of your fluorite production. I find that a well-integrated system is more effective. It is better than just many individual machines.

Each machine plays a crucial role. It helps overall efficiency. It affects final product quality. Proper selection and setup are vital. They ensure a smooth, profitable operation. This structured approach helps you reach your desired concentrate grade and recovery rate.

Crushing and screening are the first physical steps. They reduce raw ore size. They prepare it for grinding. Proper sizing significantly impacts later efficiency.

Grinding frees fluorite from associated minerals. Classification ensures correct particle size. This stage is key for flotation success.

Flotation is the core of fluorite beneficiation. It is essential for producing high-grade ceramic and acid fluorite. It separates fluorite from impurities like calcite and quartz.

Flotation can be costly. Pre-enrichment steps reduce the load on flotation. This lowers overall production costs.

After flotation, fluorite concentrate is a slurry. It needs dewatering. Sometimes, it needs drying. This improves product quality. It also reduces transport costs.

Modern fluorite plants use smart control. They prioritize environmental protection. This ensures efficient operation. It also ensures compliance with strict rules. This approach makes your fluorite processing equipment sustainable. It reduces your environmental footprint.

These systems are crucial. They protect the environment. They optimize resource use. They also enhance safety. Building an environmentally friendly beneficiation equipment line means considering these factors from the start.

Automation boosts efficiency. It improves safety. It ensures consistent operation.

Managing flotation tailings responsibly is crucial. It protects the environment. It meets regulations.

Choosing the right fluorite beneficiation equipment is important. Choosing the right supplier is equally important. A reliable partner ensures your project succeeds. I always tell clients that equipment quality and supplier support matter. You need a company that understands the complexities of the fluorite beneficiation process.

A good supplier offers more than machines. They provide expertise. They give full services. This includes design, installation, and after-sales support. This partnership is crucial for managing risks. It ensures timely delivery. It guarantees optimal performance of your fluorite processing equipment. Look for a company with a strong track record. Find one that offers complete support.

Choosing the optimal fluorite beneficiation equipment is a strategic decision. It needs deep understanding. It requires careful planning. It goes beyond selecting individual machines. You must consider your unique fluorite ore characteristics analysis. You must align with your product goals. You must also balance budget constraints with high recovery and environmental standards. A customized approach is key. It maximizes your efficiency and profitability.

I recommend a complete evaluation. This covers crushing, grinding, flotation, and dewatering. Integrate smart controls. Implement robust tailings management. Partner with a reliable supplier like ZONEDING. We offer tailored fluorite processing equipment solutions. These solutions ensure high yields. They ensure sustained success.

Since 2004, ZONEDING has been a leader in providing Mineral Processing Equipment and solutions for the global mining industry. We specialize in customized fluorite beneficiation equipment. Our machines are designed for reliability, efficiency, and optimal performance. We offer full-process solutions. This goes from initial design to installation and after-sales support. We help you achieve superior fluorite processing equipment results. We ensure your investment is a success.

Contact us today. Let our experts help you design or optimize your fluorite beneficiation equipment solution. Maximize your fluorite value with ZONEDING’s proven technology and experience.

Guide to improving ball mill output. Learn about optimizing grinding media, feed, speed, and liners to achieve maximum productivity and efficiency.

View detailsFor a 200 TPD gold processing plant, true success isn't just throughput—it's peak profitability. This scale demands a precise balance: capital investment, relentless operational efficiency, aggressive gold recovery, and unwavering environmental s...

View detailsCompare the top 4 gold extraction processes for oxidized ore. We analyze CIL/CIP, heap leaching, flotation & more on cost, efficiency, and application.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View details