High-Yield Placer Gold Scheme: A Blueprint for Maximum Profit

3595Unlock maximum gold recovery. Our guide details a high-yield, high-enrichment placer gold processing scheme, from screening to final concentration.

View detailsSearch the whole station Crushing Equipment

A ball mill is the core of many mineral processing plants. It grinds ore into fine powder. Maximizing its ball mill output improvement is vital. It directly affects your plant’s profitability. I have watched these machines work for many years. I know that optimizing them is both an art and a science. It is not just about making them spin faster. It is about understanding the whole system. This guide will show you how to boost your ball mill capacity. We will look at many factors. We will cover everything from feeding to automation. This helps you achieve a significant leap in ball mill production efficiency.

The ball mill consumes a large part of a mineral processing plant’s energy. It is often the bottleneck. This means its performance limits the entire plant’s production. Therefore, any ball mill output improvement has a huge impact. It can significantly boost your overall productivity. It also lowers your unit processing cost. For example, a small increase in throughput can mean thousands of extra tons processed each year. This translates directly into higher revenues.

On the other hand, an inefficient ball mill wastes energy. It wears out parts faster. It slows down the whole production line. This reduces your profits. Achieving peak ball mill production efficiency is not just a technical goal. It is a financial imperative. It affects how much money your business makes. Focusing on ball mill optimization can turn your plant into a more competitive and profitable operation. It ensures you get the most out of your valuable resources.

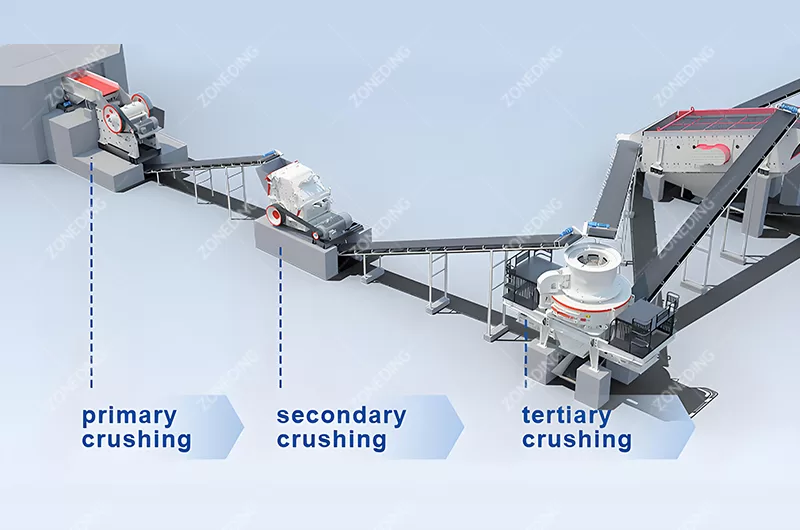

The material fed into the ball mill is crucial. Its quality directly impacts ball mill production efficiency. This is often the biggest lever for ball mill output improvement. Yet, many plant operators overlook it. They view crushing and grinding as separate. This is a common mistake. They are interconnected steps. Your ball mill is highly dependent on the crushing circuit.

Coarse, hard, or inconsistent feed reduces ball mill efficiency, dramatically raising grinding costs. Crushing material from 25mm to 15mm is inexpensive; doing so in a ball mill is significantly costlier, consuming more energy, increasing liner wear, and reducing throughput. Therefore, always optimize your crushing circuit first. Ensure your Cone Crusher and Jaw Crusher operate at their best, and screens effectively remove fines. Target the smallest, most consistent feed possible, well within your ball mill’s design limits. Never send large rocks to the ball mill to save on crushing costs; it will cost you much more in the long run.

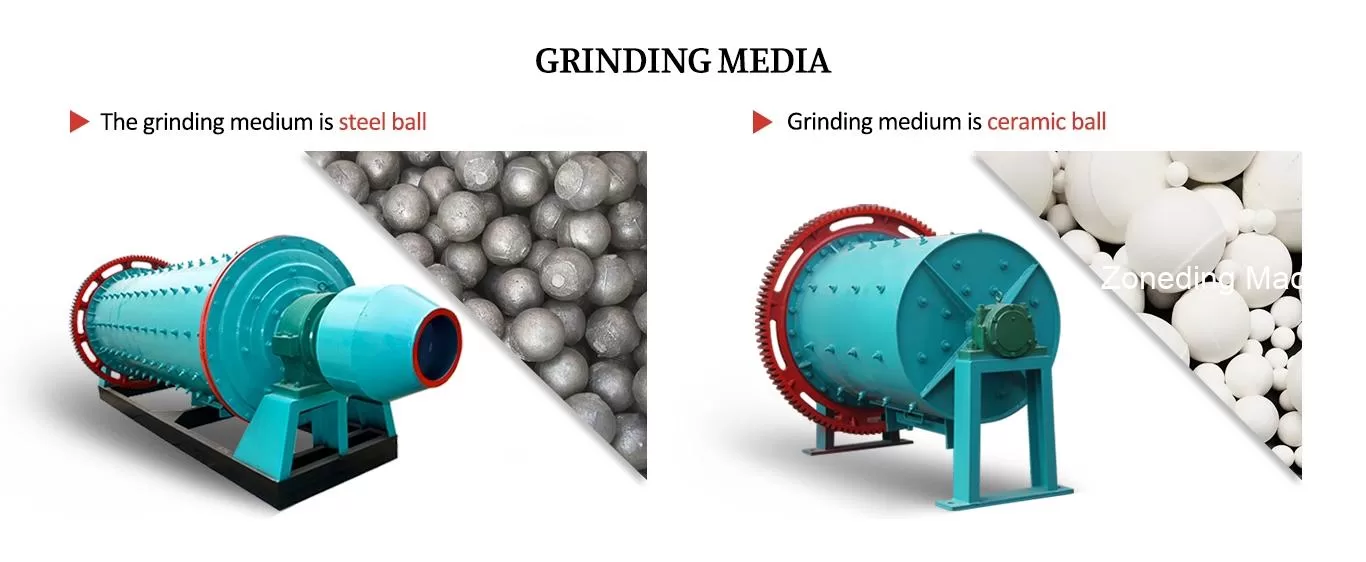

The grinding media inside the ball mill do the actual work. Selecting the right steel ball size, loading, and material is an art. Ball mill output improvement hinges on the correct distribution of ball sizes, extending beyond simply filling the mill.

Different ball sizes (coarse, medium, fine) serve distinct grinding tasks. A common error is adding only the largest balls, leading to inefficient fine particle grinding and ball segregation. Worn-out balls, which merely cushion impact, must be removed. Regular ball charge checks are crucial: maintain the correct top ball size (based on mill feed F80) and strategically add varying sizes, not just one. Monitor ball consumption for problems. Careful management of grinding media is vital to improve ball mill efficiency.

The liners inside a ball mill are more than just protective layers. They are active parts of the grinding process. Their structure and design significantly affect ball mill output improvement. They guide the balls and ore. They lift them to a certain height. Then, they allow them to fall, creating impact. This impact is essential for breaking down particles.

Worn liners significantly reduce grinding efficiency. Low lifter bars decrease impact energy, leading to ball slip, less grinding, and wasted energy. Therefore, regular inspection and proactive liner changes are crucial; don’t wait for complete wear. Consider different liner design profiles (e.g., wave, multi-wave, grid, high-low lifters), as each optimizes for specific ore hardness and grinding mechanisms (impact vs. attrition). Choosing the right liner design maximizes energy transfer, directly improving ball mill efficiency and throughput.

Two key operating parameters for ball mill optimization are its rotation speed and the concentration of the ore slurry. Getting these right is crucial for ball mill output improvement. They directly affect how well the mill grinds.

First, ball mill speed is critical. Mills operate at 65-85% of ‘critical speed’ (the centrifugal force holding balls against the shell). Too slow results in inefficient cascading and attrition, reducing impact. Too fast leads to balls centrifuging, reducing grinding and potentially damaging liners. Experiment to find the optimal speed for your ore type (e.g., higher for harder ore, lower for softer), always within manufacturer’s limits.

Second, slurry concentration control (pulp density) is equally vital. Too thick slurry cushions balls, reducing impact; too thin wastes energy on ball-on-ball contact and carries particles out too quickly. Aim for optimal pulp density (typically 65-75% solids by weight) for efficient ball-particle contact, directly boosting ball mill efficiency and throughput.

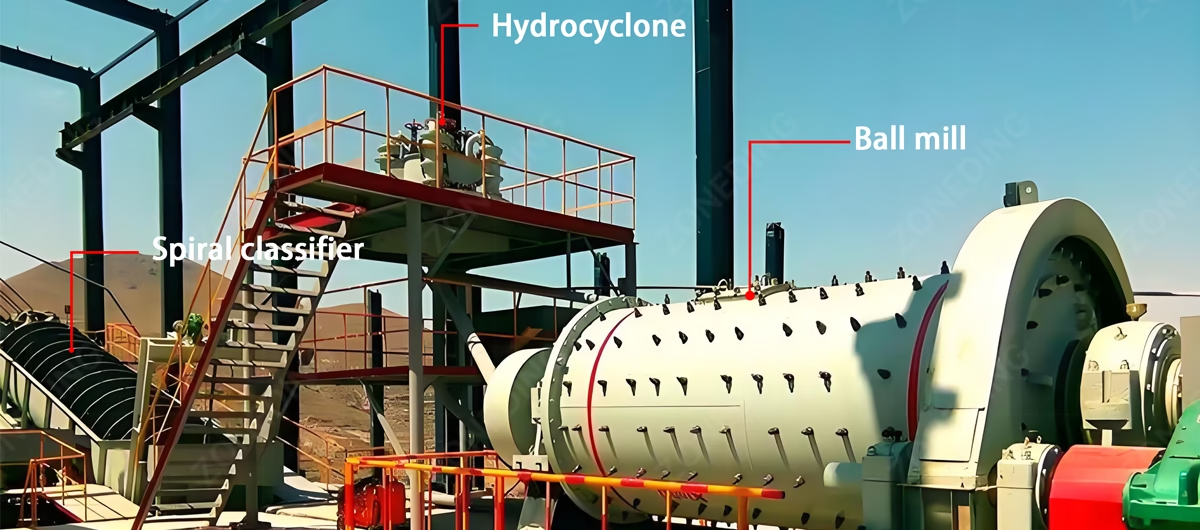

A ball mill rarely works alone. It is usually part of a closed-circuit grinding system. This system includes a classifier. The classifier is like a gatekeeper. It prevents over-grinding. It also improves overall ball mill production efficiency. An inefficient classifier can choke your ball mill.

After ore leaves the ball mill, it enters a classification device like a Hydrocyclone or Spiral Classifier. These devices separate slurry by particle size, returning only oversized particles for regrinding and sending properly sized ones to the next process. This prevents over-grinding, which wastes energy, accelerates wear on balls and liners, and reduces effective throughput. Optimal Hydrocyclone settings (feed pressure, apex, vortex finder diameters) are crucial, as their efficiency greatly impacts grinding circuit throughput and energy use. Regular monitoring and maintenance of these classifiers are essential; even small components can significantly impact ball mill output improvement.

In modern mineral processing, relying only on manual adjustments is inefficient. It leads to inconsistencies. Smart control and automation systems are now essential. They are key to achieving consistent ball mill output improvement. These systems allow the mill to operate at its best, 24/7.

We utilize advanced sensors and PLC systems for real-time monitoring of key parameters (motor power, feed rate, water, pulp density, product size). This continuous feedback enables automation control system loops to make precise adjustments (e.g., water for density, feed for motor load), maintaining optimal mill efficiency. Such a system optimizes stability, reduces human error, and facilitates continuous improvement, resulting in higher, consistent output and lower specific energy consumption. It also enables preventive maintenance through data analysis, giving operators precise control to fine-tune for maximum ball mill capacity.

Even the best-optimized ball mill cannot maintain high output without proper care. Preventive maintenance is not just about fixing things when they break.Preventing breakdowns ensures continuous, high-capacity operation, which is vital for sustained ball mill output improvement.

Regular checks and timely replacement of wear parts are crucial. Worn liners/lifters reduce grinding efficiency and can damage the mill shell. Worn grinding media (balls) cushion impacts, reducing effectiveness; thus, regular ball charge inspection and correct-sized top-ups are vital. Bearings, gears, and motors require regular lubrication/inspection to prevent costly failures and production halts. A robust maintenance schedule prevents major repairs, saves costs, and ensures reliable, efficient ball mill operation, directly supporting improve ball mill efficiency.

Optimizing the ball mill itself is important. However, true ball mill output improvement comes from a holistic view. You must look at the entire mineral processing efficiency improvement flow sheet. The ball mill is part of a larger system. Its performance affects, and is affected by, other stages.

A finer crushing circuit feed reduces ball mill work, increasing throughput. Efficient classification prevents over-grinding, freeing the mill to process new material. Inefficient downstream processes, like flotation, can indirectly strain the mill by demanding finer-than-needed grinding for liberation. Optimizing the entire production line creates a synergistic effect, significantly boosting ball mill capacity and overall mineral processing efficiency.

In my many years, I have seen common mistakes that hinder ball mill output improvement. Avoiding these can save you time and money. Here are some key errors and their solutions:

Addressing these areas systematically will lead to significant ball mill optimization. It ensures your plant runs at peak ball mill production efficiency.

Achieving significant ball mill output improvement requires a multi-faceted approach. It goes beyond simple adjustments. You must consider every aspect. This includes feed preparation, grinding media, and liner design. It also involves optimizing operational parameters. Think about mill speed and slurry density. Integrating closed-circuit systems with efficient classifiers is key. Embracing smart control and automation helps. And don’t forget rigorous preventive maintenance.

By focusing on these areas, you can greatly improve ball mill efficiency. You will enhance your ball mill capacity. This reduces your operating cost. It boosts your overall plant profitability. Remember, the ball mill is the heart of your grinding circuit. Optimizing it ensures your entire operation thrives.

Since 2004, ZONEDING has been a leader in mineral processing equipment. We specialize in providing comprehensive grinding solutions. This includes advanced Ball Mills and related equipment. Our expertise lies in designing and manufacturing high-performance machinery. We ensure reliability and efficiency for diverse applications. and We are committed to delivering tailored solutions. We help you meet your unique production goals. Our global presence and extensive service network support your operation every step of the way.

Contact us today to discuss your grinding optimization needs. Let us help you achieve maximum ball mill production efficiency and output.

Unlock maximum gold recovery. Our guide details a high-yield, high-enrichment placer gold processing scheme, from screening to final concentration.

View detailsMobile crushing plants have evolved from clumsy, towable units into the highly integrated, tracked giants of today. They promise flexibility and rapid deployment, changing how countless mining and construction projects operate. However, this "plu...

View detailsExplore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsThis expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View details