Secrets to Jaw Crusher Maintenance: Save Costs, Boost Output

4049Optimize jaw crusher maintenance. Prevent breakdowns, maximize uptime, and ensure consistent, high-efficiency crushing with our practical guide.

View detailsSearch the whole station Crushing Equipment

Setting up a gold ore beneficiation plant is a big project. You need to make smart choices for equipment. The right equipment helps you get the most gold from your ore. This is called maximizing the gold recovery rate. The type of gold ore you have is very important. Its characteristics guide every decision. This guide will walk you through each step. You will learn how to pick the best gold processing equipment. This will help you succeed and make good profits.

Starting a gold processing plant requires significant investment. Many new projects fail. They fail because they use a “standard” gold ore beneficiation plant equipment list. This is a big mistake. There is no one-size-fits-all solution for gold processing. Each gold deposit is unique. Its ore characteristics vary greatly. You need to choose equipment that matches your specific ore. This is critical for success.

My experience shows that the type of gold, its size, and how it is held within the rock matter most.Is the gold free or sulfide-bound? What is the ore’s hardness – hard or soft?These factors determine your entire gold beneficiation process. Getting the equipment selection right can save you millions. It boosts your gold recovery rate. It also lowers your operating cost. A poorly chosen plant might recover only 60% of the gold. A well-designed one can recover over 90%. This difference decides if your investment makes money or loses it.

The first step in any gold ore beneficiation plant is to reduce the size of the raw ore. This is the crushing and screening stage. The goal is to break large rocks into smaller pieces. These smaller pieces are then ready for grinding. We must do this efficiently. We also need to avoid making too many fine particles too early. Over-crushing wastes energy. It can also make gold recovery harder later.

We typically use a multi-stage crushing circuit. First, a Vibrating Feeder controls the flow of ore. It sends large rocks to the primary Jaw Crusher. The jaw crusher breaks the largest pieces. Then, the material goes through a Vibrating Screen. The screen separates material by size. Oversized material goes to a secondary Cone Crusher for further reduction. Sometimes, a tertiary cone crusher is also used. These crushers reduce the ore to a size ideal for the grinding stage. This size is typically 20-30 mm. Efficient crushing ensures that the ore is ready for the next step.

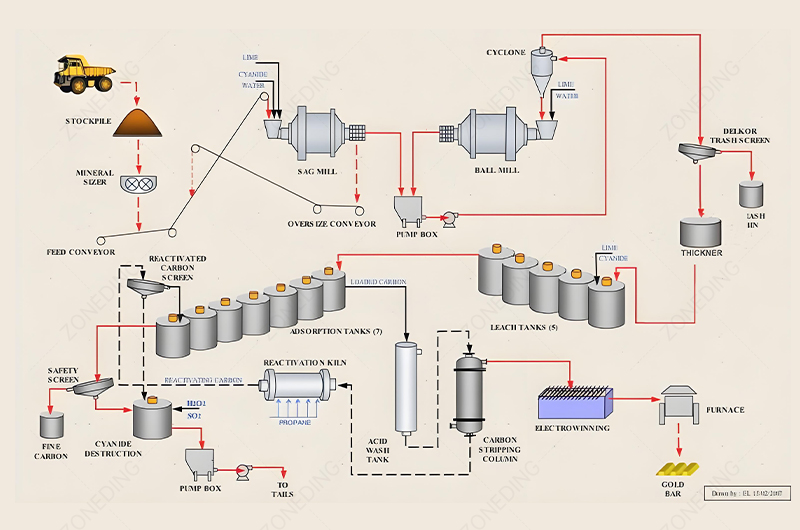

After crushing, the ore moves to the grinding and classification circuit. This is often the most energy-intensive part of the gold beneficiation process. Here, the main goal is to grind the ore to a very fine powder. This process liberates the tiny gold particles. It separates them from the surrounding host rock. This is called full gold mineral liberation. Without this, you cannot recover the gold efficiently.

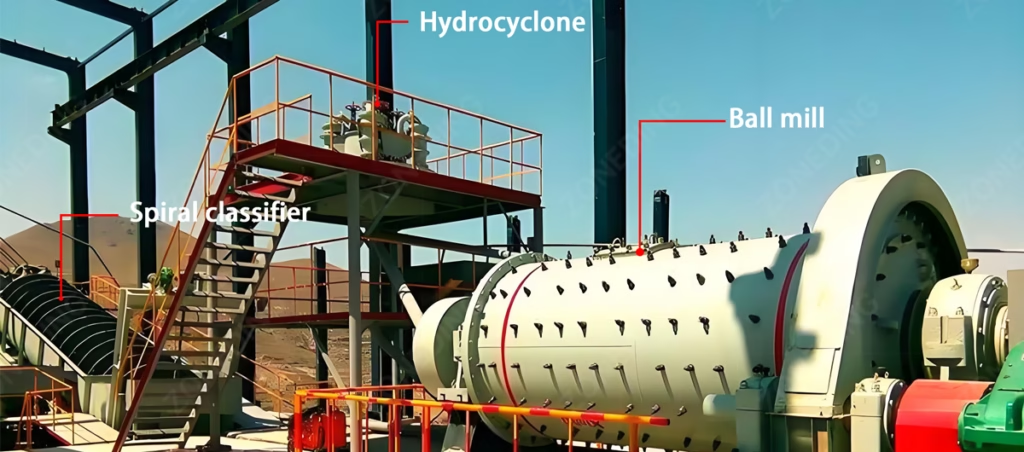

We use Ball Mills for this. Inside the mill, steel balls tumble and crush the ore. They grind it to the target size. This size can be as fine as 75-150 microns. The ground ore, now a slurry, then goes to a classification unit. Often, this is a Spiral Classifier or a Hydrocyclone. These machines separate the slurry based on particle size. Oversized particles return to the ball mill for more grinding. This forms a closed circuit. Properly sized particles move on to the next recovery stage. This precise control ensures gold is fully liberated. It also prevents over-grinding, which wastes energy.

Choosing the right gold beneficiation process is critical. It depends entirely on your ore characteristics. There is no single best method for all gold ores. I often see people trying to force the wrong process onto their ore. This leads to low recovery and high costs. You need to understand your gold’s nature. This will guide your decision.

We mostly use three main processes:

Many modern plants use a combination of these methods. For example, they might use gravity first to recover coarse gold. Then, they use flotation for sulfide-bound gold. Finally, they use cyanidation for the remaining fine gold. This multi-stage approach maximizes the gold recovery rate.

| Gold Ore Type | Typical Gold Occurrence | Primary Recovery Method | Key Equipment Used |

|---|---|---|---|

| Placer Gold / Alluvial Gold | Coarse, free gold particles | Gravity Separation | Jigging Machines, Centrifugal Concentrators, Shaking Tables |

| Vein Gold (Free, Coarse) | Free, often coarse gold particles | Gravity Separation (early stage) | Centrifugal Concentrators, Shaking Tables |

| Sulfide-Associated Gold | Gold encapsulated in pyrite, chalcopyrite, etc. | Flotation | Flotation Machines, Conditioning Tanks |

| Oxidized Gold / Fine Disseminated Gold | Fine gold in oxidized matrix | Cyanidation (CIL/CIP) | Leaching Tanks, Adsorption Tanks, Carbon Columns |

| Refractory Gold (complex sulfides) | Gold in very fine sulfides | Flotation + Roasting/Pressure Oxidation + Cyanidation | Flotation Machines, Autoclaves, Leaching Tanks, CIL/CIP |

For easily recoverable, coarse gold, gravity separation is often the first and most cost-effective choice. This method uses the difference in density between gold and other minerals. Gold is very heavy. It settles faster than lighter waste minerals. This allows us to separate it with simple, proven gold processing equipment.

For coarser particles, we often start with Jigging Separator Machine; jigs use pulsating water to separate heavy gold. For finer free gold, Centrifugal Concentrators are highly effective, recovering even very fine gold using centrifugal force, often placed in the grinding circuit for early recovery. Subsequently, Shaking Tables clean the gold concentrates, further separating gold from other heavy minerals. Gravity separation is low-cost, chemical-free, and recovers gold early, reducing the load on later processes and protecting against loss. A modern gold ore beneficiation plant almost always includes some form of gravity recovery.

When gold is intimately associated with sulfide minerals, flotation becomes a crucial step. This is common in many gold deposits. In these ores, the gold is often too fine to be recovered by gravity. It is also trapped within the sulfide crystals. Flotation separates these gold-bearing sulfides from the lighter waste rock. It does this by leveraging differences in mineral surface properties.

The process begins with conditioning: ground ore slurry is mixed in Mixer tanks with reagents that selectively attach to sulfide minerals, making them water-repellent. Then, in the Flotation Machine, air bubbles are introduced. Hydrophobic, gold-bearing sulfide particles attach to these bubbles, rising as a froth (rich in gold and sulfides) which is collected as concentrate, while waste minerals remain in the water. Flotation is highly effective for concentrating gold from complex sulfide ores, producing a smaller, easier-to-process concentrate (e.g., by cyanidation/roasting). This significantly boosts the overall gold recovery rate.

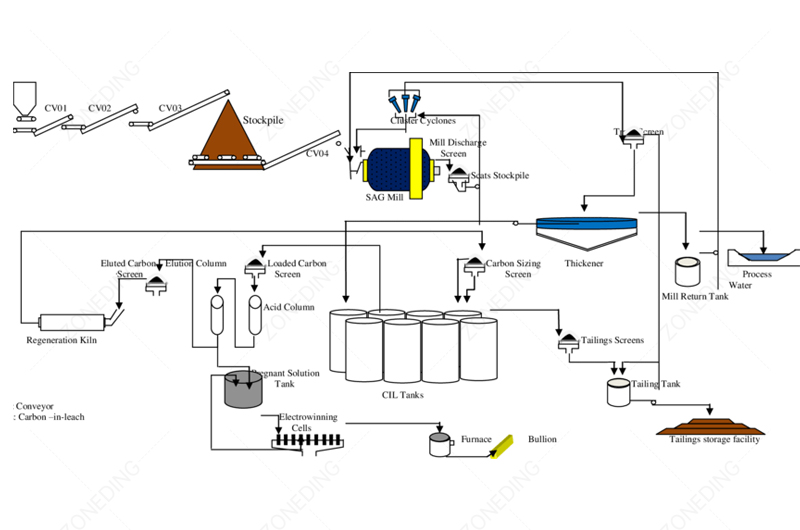

For ores with fine, disseminated gold, or after flotation of gold-bearing sulfides, cyanidation is often the preferred method. The CIL process equipment (Carbon-in-Leach) and CIP (Carbon-in-Pulp) are widely used. They achieve the highest gold recovery rate for such ores. These methods dissolve gold into a cyanide solution. They then use activated carbon to adsorb the gold.

In the CIL process, finely ground ore slurry enters a series of Leaching Tanks. Here, cyanide solution dissolves gold, and simultaneously, activated carbon is added to adsorb the dissolved gold directly from the pulp, combining leaching and adsorption. CIP is similar but separates these steps: gold is first leached, then the pregnant solution is separated from solids and goes to carbon columns for adsorption. CIL is often favored for its robustness against “preg-robbing” minerals. Large, fine screens separate carbon from the ore pulp to prevent loss, ensuring maximum gold capture from the dissolved solution.

Once activated carbon is loaded with gold, we need to extract that gold. This part of the gold processing equipment chain involves the desorption and electrowinning system. It eventually leads to the production of gold doré bars.

First, loaded carbon moves to an elution circuit where, in a process called desorption electrolysis system, hot, high-pressure cyanide solution and caustic soda strip the gold, releasing it into a concentrated solution. The “pregnant” elution solution then flows into electrowinning cells which use electricity to deposit dissolved gold onto steel wool cathodes, forming a gold sludge. This sludge is washed, dried, mixed with fluxes, and melted in a smelting furnace to produce 80-90% pure gold doré bars, which are shipped to a refinery for further purification. This entire system ensures efficient and safe gold recovery from carbon, transforming it into a tangible product.

After gold extraction, a large volume of slurry remains. This slurry contains process water and waste material (tailings). Thickening and dewatering are crucial steps here. They serve two main purposes. First, they recover valuable water for reuse in the plant. This reduces water consumption. Second, they reduce the volume of tailings. This lowers tailings management costs.

The slurry first flows into High Efficiency Concentrator (thickeners). In these large tanks, solids settle to the bottom. Clear water overflows from the top. This recovered water is then recycled back into the plant. This is especially important in arid regions. The thickened slurry, now much denser, is then pumped to filter presses. Filter press remove even more water from the tailings. They create a solid filter cake. This cake is much easier to handle and dispose of. For example, it can be dry-stacked. This reduces the footprint and environmental risk of tailings storage. Effective thickening and dewatering significantly contribute to reducing the overall operating cost of a gold ore beneficiation plant.

Environmental compliance is non-negotiable for any modern gold processing plant. It is critical for gaining and keeping a social license to operate. Improper tailings management or wastewater discharge can lead to severe penalties. It can also cause irreversible environmental damage. We must plan for these aspects from the start.

Post-gold recovery, treating residual cyanide in tailings slurry is a key challenge, demanding destruction before discharge. A cyanide detoxification plant addresses this, typically employing methods like SO2/Air, Caro’s Acid, or hydrogen peroxide to neutralize the cyanide. Treated tailings then move to a tailings storage facility (TSF), which requires design and operation to the highest environmental standards, including robust dams, liner systems, and continuous monitoring. All other wastewater also needs treatment to meet local environmental regulations. While these systems add to the operating cost, they are an essential investment for environmental protection and long-term operational viability.

While the core gold processing equipment drives the main process, many auxiliary systems are equally important. These “unsung heroes” ensure the entire gold ore beneficiation plant runs smoothly, safely, and efficiently. Overlooking them can lead to unexpected downtime and increased costs.

Essential auxiliary equipment list items include:

Each piece of this auxiliary equipment list plays a vital role. They ensure your gold processing plant operates consistently.

The gold industry is always evolving. Several key trends are shaping gold beneficiation process in 2025. These trends aim to improve efficiency, reduce costs, and enhance environmental performance.

These trends aim to make gold ore beneficiation more sustainable and profitable. For you, this means staying updated. You need to consider new technologies for future projects or plant upgrades.

Question 1: Why is a proper equipment list crucial for your gold project’s success?

A proper equipment list is critical because gold ore characteristics vary widely. There is no standard plant. Matching the right gold processing equipment to your specific ore maximizes gold recovery rate and minimizes operating cost. This directly impacts profitability.

Question 2: How do ball mills and classifiers work to liberate gold minerals?

Ball mills grind the ore to a fine powder, freeing tiny gold particles from the rock. Spiral classifiers or hydrocyclones then separate this slurry. They send oversized particles back to the mill for further grinding. They let finely ground, liberated gold move to the next stage.

Question 3: How do gravity separation devices recover coarse free gold at low cost?

Gravity separation devices like jigging separator machine, centrifugal concentrator, and shaking table use gold’s high density. They separate it from lighter waste minerals. This is a simple, cost-effective method. It avoids expensive chemicals and recovers gold early in the process.

Question 4: What CIL process equipment is essential for the highest recovery rates?

In the CIL process, leaching tank are essential. Here, gold dissolves into a cyanide solution. Activated carbon is also added. It adsorbs the dissolved gold directly from the pulp. This integrated approach, with robust carbon screening, ensures high gold recovery.

Question 5: What equipment do you need for environmental compliance in gold ore beneficiation?

You need a cyanide detoxification plant to neutralize residual cyanide in tailings. You also need a well-designed tailings storage facility (TSF). It must have proper liners and monitoring. Wastewater treatment systems are also required. These ensure all discharges meet environmental standards.

Designing and operating a gold ore beneficiation plant is a complex endeavor. It requires careful planning and precise equipment selection. You must understand your ore’s unique characteristics. This is the foundation for choosing the right gold beneficiation process. It determines your crushing, grinding, and recovery methods. Whether you use gravity separation, flotation, or CIL process equipment, each stage needs careful consideration. This includes the subsequent gold refining and environmental compliance.

The goal is always to maximize your gold recovery rate while minimizing your operating cost. This ensures a strong return on your investment. ZONEDING can help you achieve this. We offer custom-designed solutions and reliable gold processing equipment.

Since 2004, ZONEDING has been a trusted manufacturer of mineral processing equipment. We specialize in providing comprehensive solutions for gold mining operations worldwide. Our expertise covers everything. This includes detailed ore testing, custom plant design, and the supply of high-performance machinery. We help you build efficient and profitable gold ore beneficiation plant. We are committed to supporting your success.

Contact us today. Let us help you unlock the full potential of your gold deposit. We will provide the right gold processing equipment for your specific needs.

Optimize jaw crusher maintenance. Prevent breakdowns, maximize uptime, and ensure consistent, high-efficiency crushing with our practical guide.

View detailsThe grinding process determines the success of mineral separation. Proper selection of grinding equipment in mining ensures a high liberation degree for mineral particles. This technical guide analyzes ball mills, rod mills, and SAG technology fo...

View detailsGuide to improving ball mill output. Learn about optimizing grinding media, feed, speed, and liners to achieve maximum productivity and efficiency.

View detailsLearn correctly select stone crushers for primary, secondary, tertiary stages. Understand jaw, cone, impact, and VSI crushers for optimal aggregate production.

View details