Optimizing Gold Elution: Understanding Its Advantages & Problems

3911This article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsSearch the whole station Crushing Equipment

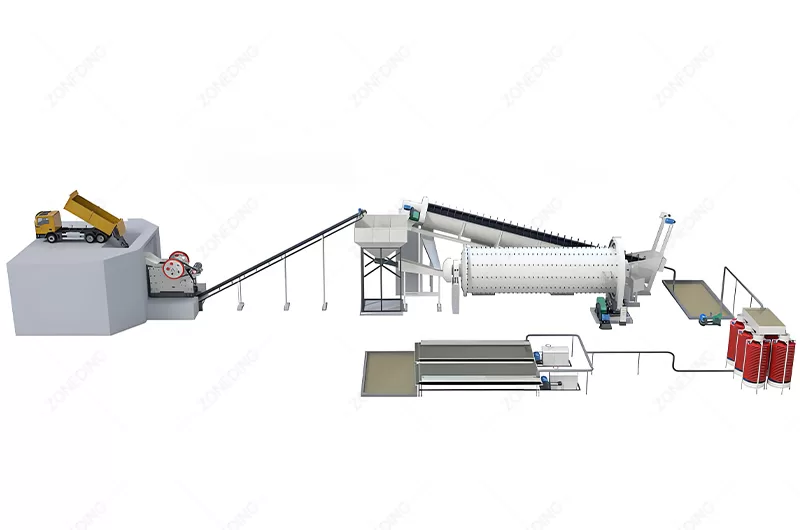

The grinding process determines the success of mineral separation. Proper selection of grinding equipment in mining ensures a high liberation degree for mineral particles. This technical guide analyzes ball mills, rod mills, and SAG technology for the 2026 market. Efficient grinding circuits reduce energy waste and improve flotation recovery. The following content provides a detailed evaluation of grinding principles and equipment selection.

The primary goal of grinding is to reach the target liberation degree of the mineral. Liberation happens when valuable mineral particles separate from waste rock. If particles stay too large, the mineral remains trapped inside the rock. Flotation chemicals cannot reach the mineral surface. This leads to low recovery rates and lost profit. But if particles become too small, they turn into “slimes.” Slimes are very difficult to recover and interfere with chemical balance in Flotation Machines.

Precision in particle size control is the foundation of efficient mineral processing. A high-quality grinding circuit produces a narrow range of particle sizes. This consistency ensures the flotation stage operates at peak efficiency. Grinding intensity must match the physical properties of the specific ore. Harder ores require more impact force. Softer ores need gentle grinding to prevent over-pulverization. Every percent increase in the Ore liberation degree control results in improvements in final concentrate grade.

Smaller particles have a larger total surface area for a given mass. This increases the contact area for flotation reagents. But the energy cost to create surface area is very high. The plant must find the “economic grind size” where recovery profit exceeds energy cost.

Grinding machines serve several critical industries beyond basic mining. I see these machines in metallic ore processing, industrial mineral production, and construction. In metallic mining, they are essential for gold, copper, and Iron Ore Processing Plant operations. These minerals must be ground to a fine powder to release the metals. Industrial minerals like limestone, phosphate, and gypsum also require grinding for chemical use. Many of these products go into fertilizers or building materials. The grinding process ensures the powder is fine enough for chemical reactions.

I also find grinding machines in the aggregate and construction waste recycling sector. Stone Crusher units break big rocks into small stones. Then, grinding machines turn those stones into fine sand for high-quality concrete. Another growing area is the recycling of slag from steel mills. I use grinding mills to recover small pieces of metal from the waste slag. This process turns waste into profit and helps the environment. Cement production is another huge application area. Grinding mills mix raw materials and then grind the final clinker into the cement powder you buy in bags.

Grinding technology is used in power plants to grind coal into a fine dust for burning. It is also used in the glass industry to grind silica sand. Every industry that needs a fine powder uses some form of a grinding mill. I choose the specific mill based on how hard the material is. For example, I use different machines for soft coal than I do for hard iron ore.

| Application Sector | Typical Material | Target Product | Primary Equipment |

|---|---|---|---|

| Metal Mining | Gold, Copper, Iron | < 0.1 mm | Ball Mill / SAG |

| Construction | Limestone, Sand | High-quality Sand | Rod Mill |

| Energy | Coal | Fine Coal Dust | Ball Mill |

A ball mill is the preferred choice for fine grinding and versatile mineral processing. This machine uses steel balls as grinding media. The balls provide a large surface area for grinding through impact and attrition. Ball mill working principle and application are suitable for a wide range of ores. These include hard quartz and soft limestone. The ball mill produces a very fine final product. This size is often below 74 microns. It is the standard equipment for the second stage of grinding in most large-scale plants.

The ball mill is a reliable and robust machine. It handles variations in ore hardness better than other grinding technologies. Maintenance is straightforward because grinding media is simple to load. Ball mills work in both open-circuit and closed-circuit systems. In a closed circuit, the mill works with a Spiral Classifier or a hydrocyclone. This setup ensures that only small material leaves the circuit. The ball mill is also highly scalable. Sizes range from small lab units to 10-meter diameter industrial machines.

The choice depends on the required final fineness and daily throughput. The length-to-diameter ratio is a key design factor. A longer mill allows for more residence time and a finer product. A larger diameter provides more impact energy for hard rocks.

| Mill Type | Media Type | Final Product Size | Primary Use |

|---|---|---|---|

| Ball Mill | Steel Balls | < 0.074 mm | Fine grinding |

| Rod Mill | Steel Rods | 0.5 mm – 2 mm | Coarse grinding |

| SAG Mill | Ore + Balls | 0.1 mm – 3 mm | Primary grinding |

The Rod Mill uses line contact between steel rods to provide selective grinding. This mechanism is the key to preventing “over-grinding” or excessive fines. The rods stay parallel inside the mill. When a large rock enters, it forces the rods apart. This ensures that the grinding force focuses on the largest particles first. Smaller particles fall through the gaps between the rods. They avoid further grinding. This selective action produces a product with a very uniform size distribution.

Rod mills are essential for gravity separation circuits. Minerals like tungsten, tin, and tantalum are very brittle. If these minerals are ground too fine, they turn into slimes. Slimes cannot be recovered by Shaking Tables or jigs. The rod mill protects these minerals by reducing particle size gradually. The product has a sandy texture rather than a floury texture. This texture is ideal for the next stage of processing. Rod mills also use less energy when the target size is coarse.

Steel rods must be replaced as they wear down. Broken or bent rods must be removed. This prevents tangling inside the mill. The operator should maintain a consistent rod charge for the best results. Grinding media consumption assessment is part of weekly maintenance routines.

Differences between AG and SAG mills center on the use of grinding media. Autogenous (AG) mills use the ore itself to grind the ore. Semi-Autogenous (SAG) mills use ore plus a small charge of steel balls. These machines take the place of second and third stages of traditional crushing. Large rocks enter the mill directly after the primary crusher. This reduces the number of conveyors, screens, and crushers needed in the plant layout.

AG and SAG mills are ideal for large-capacity plants. They handle wet and sticky ores. These ores would clog a standard cone crusher. The impact of large rocks falling on each other is very effective. It breaks down soft or clay-rich material. But AG mills require a specific type of ore. The ore must be hard enough to act as a grinding medium. If the ore is too soft, the AG mill will not work. In these cases, the SAG mill is the better choice. Steel balls provide the necessary impact force. This technology simplifies the flowsheet and reduces the total footprint.

Wet grinding process flow is the most common method in mineral processing. It uses water to move the ore through the mill and into the next stage. Wet grinding uses 30% less energy than dry grinding for the same size reduction. It also eliminates the problem of dust. Slurry transport is easier than moving dry powder. But wet grinding requires a water source and downstream dewatering equipment.

Dry grinding is used when the final product must stay dry. Examples include cement or some chemical processes. Dry grinding requires powerful air-flow systems to remove fine dust from the mill. It causes more wear on liners because there is no water to lubricate the particles. The decision depends on the mineral properties. If the mineral reacts with water, dry grinding is the only option. If the next step is flotation, wet grinding is the standard choice.

The discharge mechanism determines residence time and pulp level inside the mill. An overflow mill allows slurry to flow out naturally through the trunnion. This happens when the level gets high enough. This design is simple. It has very few moving parts. It is commonly used for fine grinding stages. Particles stay in the mill longer. This results in a finer product. But there is a risk of over-grinding because material does not leave the mill immediately.

A grate discharge mill uses a slotted plate at the end of the drum. A set of lifters behind the plate picks up the slurry. It forces the slurry out of the mill. This maintains a very low pulp level. The low pulp level allows steel balls to hit the ore directly. Water does not cushion the impact. This creates very high grinding efficiency for coarse material. Grate discharge mills are often used for the primary stage of grinding. They have a higher capacity than overflow mills of the same size.

Grinding efficiency depends on the balance of three core factors. The feed size must match the size of the grinding media. Large balls are needed for large rocks. Small balls are better for fine material. The mill speed is usually set at 70% to 80% of the critical speed. This speed ensures balls are carried up and then dropped on the ore. If the speed is too high, balls stay stuck to the wall. If it is too low, balls just roll at the bottom.

Steel ball grading is the mix of different ball diameters inside the mill. A good mix ensures that gaps between large balls are filled with small balls. This maximizes the contact points. Feed size should be as small as possible. The rule is “crush more, grind less.” Breaking a rock in a crusher is much cheaper than grinding it in a mill. Small feed allows the use of smaller grinding balls. This increases the total surface area for grinding.

Choosing the right Mining mill liner maintenance strategy starts with material selection. Metal liners made of manganese steel or chrome-moly steel are standard for high-impact grinding. These liners are very tough. They handle large rocks well. But they are heavy and loud. They also require a long time to replace. Shutdowns for metal liner changes can take several days.

Rubber liners are an excellent alternative for secondary grinding. Rubber is much lighter than steel. This reduces the energy needed to spin the mill. It also lowers the noise level. Rubber liners have a longer life in fine-grinding environments. Abrasion is the main cause of wear there. Some modern plants use composite liners. These combine steel inserts with a rubber base. This provides impact resistance and weight benefits. Frequent inspections of liner bolts and thickness prevent damage to the mill shell.

The classification stage provides feedback for mill operation. If a Hydrocyclone or a Spiral Classifier detects too much coarse material, the circulating load increases. This tells the operator to reduce mill feed or check the ball charge. A high-efficiency classification system ensures the mill only processes rocks that need more work. This reduces invalid grinding of particles that are already small enough.

Closed-circuit grinding is more efficient than open-circuit grinding. It prevents over-grinding by removing fine particles as soon as they reach target size. The ratio of the material returned to the mill versus the new feed is the circulating load. A high circulating load usually means better efficiency but requires larger classification equipment. Maintaining a steady circulating load is the secret to a stable mineral processing plant.

Grinding accounts for up to 50% of the total energy cost of a mine. Optimizing this cost requires a detailed Grinding energy consumption analysis. The Bond Work Index is the standard tool for measuring energy needs. By monitoring the power draw of the mill, the plant can adjust the ball charge. Over-filling the mill with balls does not improve grinding. it only increases the power cost and liner wear.

Steel consumption is the other major cost. Steel balls and liners wear away every hour. Using high-quality forged steel balls reduces the wear rate per ton of ore. The plant should also monitor the pH of the slurry. Corrosion can increase steel loss by 20%. Adding lime to the mill can neutralize the acid. This protects the steel. Reducing the scrap rate of balls—balls that become too small—is another way to save money.

Automatic feeding systems maintain a constant power-to-feed ratio. Grinding mills work best when they contain the correct mixture of ore, balls, and water. If the feed stops or slows down, balls hit liners directly. This causes extreme wear and can crack the mill shell. If the feed is too fast, the mill will “choke.” A choked mill cannot grind anything and must be stopped.

An auto-feeding system uses sensors on conveyor belts and the mill motor. If motor power drops, the system increases the feed rate. If the noise level inside the mill becomes too loud, the system knows the mill is empty. It adds more ore. This constant adjustment keeps the mill at its sweet spot. It also ensures the final product size stays consistent for the Flotation Machines.

Ore hardness determines the configuration of the grinding circuit. Hard ore requires a high-impact primary stage. This is often a SAG mill or a rod mill. A second stage ball mill then follows to reach the final fineness. For very hard ore, a three-stage circuit may be necessary. This distributes the work and prevents any single machine from over-heating or wearing too fast.

Medium hardness ore is often handled by a SAG mill followed by a ball mill. Soft ore can sometimes be processed in a single stage. This is a large ball mill in a closed circuit with hydrocyclones. Configuration also depends on the required throughput. Larger plants favor SAG mills because they replace several crushing stages. Smaller plants prefer the simplicity of a jaw crusher followed by a ball mill.

The 2026 market is moving toward digital twin technology and variable speed drives (VSD). These innovations allow the plant to adjust mill performance in real-time. New Selection of grinding equipment in mining includes high-pressure grinding rolls (HPGR) for pre-treatment.

Question 1: What is the ideal ball size for a primary ball mill?

Ball size depends on the feed size. For a 25mm feed, a mix of 80mm and 60mm balls is common. A calculation is needed to find the exact grading of the media for different ore types.

Question 2: Why is the mill making a high-pitched metallic sound?

This sound means steel balls are hitting the liners directly. The mill is likely under-fed. Increase the ore feed immediately to protect the liners from damage.

Question 3: How often should new steel balls be added?

New balls should be added every day based on the tonnage processed. This maintains a consistent ball charge. It ensures the grinding efficiency does not drop over time.

Question 4: Can a ball mill handle wet material?

Yes. Ball mills are very effective for wet grinding. Water helps move the material through the mill. It also reduces dust and energy use compared to dry grinding.

Question 5: What is the difference between a spiral classifier and a hydrocyclone?

A Spiral Classifier uses mechanical screws to lift coarse material. A Hydrocyclone uses centrifugal force. Cyclones are smaller and handle higher volumes but require more power.

ZONEDING is a professional manufacturer of Beneficiation Equipment and grinding machinery. Since 2004, the company has provided high-efficiency ball mills, rod mills, and complete mineral processing solutions. ZONEDING employs 15 expert engineers for mill design and optimization. The factory has exported equipment to over 120 countries. ZONEDING offers factory-direct sales to ensure competitive pricing for global mining partners.

Contact ZONEDING for grinding circuit design and equipment quotes.

This article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsLearn correctly select stone crushers for primary, secondary, tertiary stages. Understand jaw, cone, impact, and VSI crushers for optimal aggregate production.

View detailsThis expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View detailsHigh gold recovery from sulfide ores. This guide details best beneficiation processes including grinding, flotation, and advanced pre-treatment methods.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy