Expert Solutions for Crushing & Grinding Equipment Problems

3581Quickly diagnose & fix common crusher & grinder issues. Our guide covers overheating, blockages, & wear with practical solutions.

View detailsSearch the whole station Crushing Equipment

You’re moving tons of dirt. Your machines are running all day. But at the end of the week, the amount of gold in your hand is a disaster. Your recovery rate is low, and the concentrate you do have is mostly worthless black sand. If this sounds familiar, your problem isn’t a single bad machine. The root cause is your entire placer gold process flow.

Achieving both a high recovery rate (catching all the gold) and a high enrichment ratio (producing a high-purity concentrate) is not about a magic bullet. It’s about designing a logical, multi-stage system where each step prepares the material perfectly for the next. This is how you stop losing gold and start running a profitable mine.

The problem is that sticky clay is the greatest thief in placer gold mining. It acts in two destructive ways. First, it forms hard, dense balls that trap fine gold particles inside. Your screens and sluices just wash over these clay balls, sending them—and the gold inside—directly to your waste pile. Second, clay contaminates your water, creating a thick, high-viscosity slurry. Gold, especially fine gold, cannot settle through this mud. It stays suspended and flows right out with your tailings.

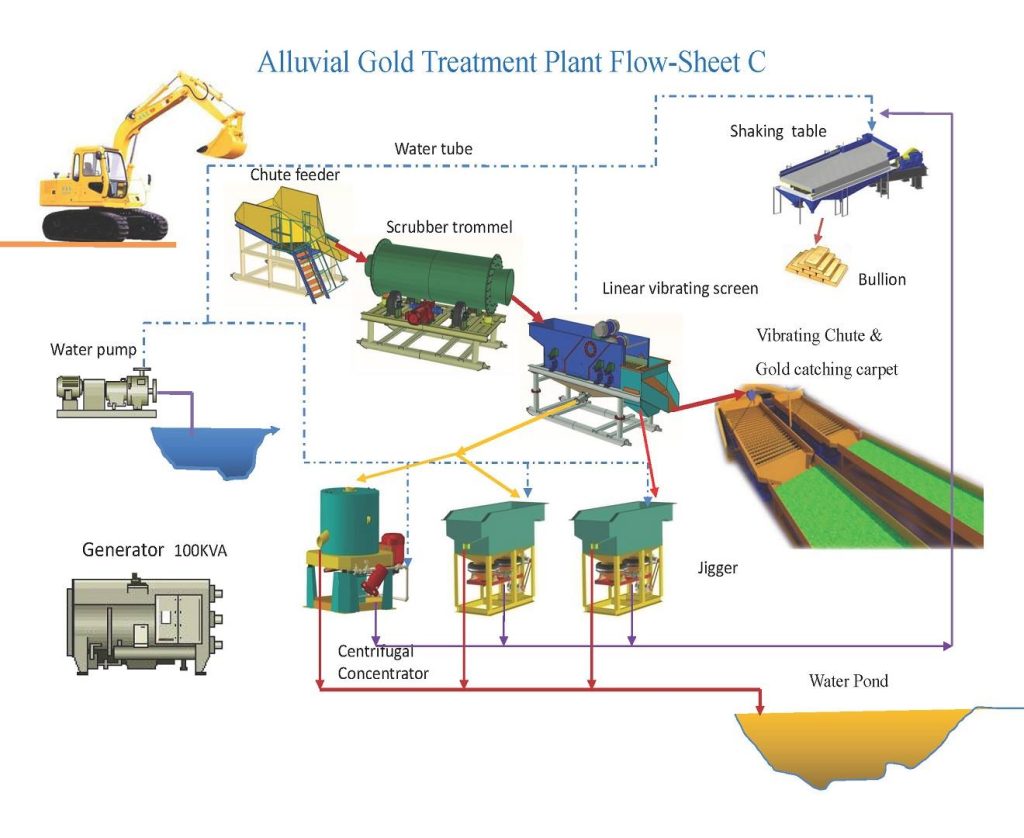

The solution is an aggressive, two-part washing and desliming stage. You must liberate the gold from the clay before any concentration begins. A simple spray bar on a screen is not enough. You need a dedicated rotary scrubber or a long-trommel with a scrubber section. This machine uses intense, rock-on-rock grinding to break apart clay balls. High-pressure water then turns the liberated clay into a slurry of fine particles, known as slimes. This entire slime fraction should be separated from the valuable sandy material before the concentration stages.

The goal of screening is to divide and conquer. After washing, you have a slurry containing everything from fine sand to coarse gravel. No single piece of recovery equipment can efficiently handle this wide range of sizes. Trying to do so is the main reason for gold loss. A machine set up to catch 10mm nuggets will let 0.1mm fine gold wash away. A machine calibrated for fine gold will be overwhelmed and choked by coarse gravel.

A well-configured vibrating screen or trommel screen is your most important process control tool. It separates the washed ore into distinct size fractions. A typical setup might be:

The goal of the roughing stage is bulk reduction. Your ore might contain only a few grams of gold per ton. The rougher’s job is to get rid of 80-90% of the worthless sand and gravel as quickly as possible, while capturing the majority of the liberated gold. This is not about producing a clean concentrate; it’s about making a fast, “rough” cut.

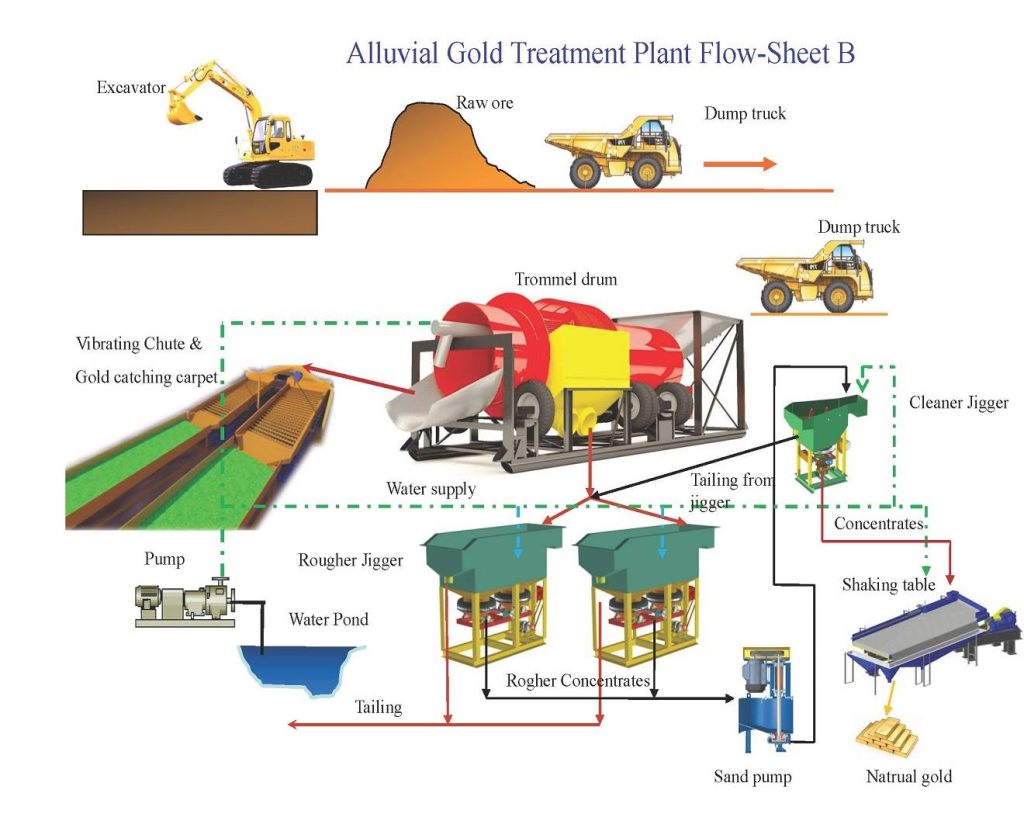

Jig concentrators and sluices are the primary tools for roughing. Jigs use a pulsating water column to stratify material, allowing heavy gold to sink while washing away lighter sand. They are excellent for the coarse (2mm-10mm) fraction because they can handle high volumes and are relatively robust. A well-run sluice can also act as a rougher. The key is to understand that the concentrate from this stage will be low-grade and high-volume, and the tailings will still contain some fine gold. That’s not a failure; it’s the specific job of the rougher.

The goal of the scavenging stage is to recover the fine gold that the roughing stage missed. The tailings from your jigs or sluices are not barren. They contain the valuable fine and “flour” gold that was too small or light to be captured in the high-volume roughing circuit. Discarding these tailings is like throwing away your profits. This is where you hunt for every last paying gram.

A centrifugal concentrator is the essential tool for scavenging. These machines spin at high speeds, creating immense G-forces (50 to 300 times the force of gravity). This force pins even microscopic gold particles against the wall of the concentrator bowl, capturing gold that would be impossible to recover with a standard sluice. By feeding the fine (-2mm) fraction and the rougher tailings to a centrifugal concentrator, you are actively preventing fine gold recovery losses and dramatically increasing your gold recovery rate.

The goal of the cleaning stage is to achieve a high enrichment ratio. The concentrates from your roughing and scavenging stages have a high gold yield, but they are low-grade. They are mostly black sand (magnetite, ilmenite, etc.) with some gold mixed in. The cleaning stage’s job is to remove this black sand and produce a final, high-purity product that is ready for smelting.

A shaking table is absolutely essential for the final cleaning stage. It uses a combination of vibration and a film of water to separate particles based on both size and density. When the low-grade concentrate is fed onto the table, you can literally see the minerals separate into distinct bands: a bright yellow ribbon of pure gold, a dark band of black sand, and a lighter band of silica. You can then physically separate these products. For a truly professional setup, you can even use a magnetic separator to remove magnetite before the shaking table, making its job even easier and more efficient.

There is no “one-size-fits-all” placer gold process flow. The correct configuration depends entirely on your ore. A pre-investment ore analysis is critical. Here is a simplified guide to customizing your design:

| Ore Type | Key Challenge | Recommended Process Flow |

|---|---|---|

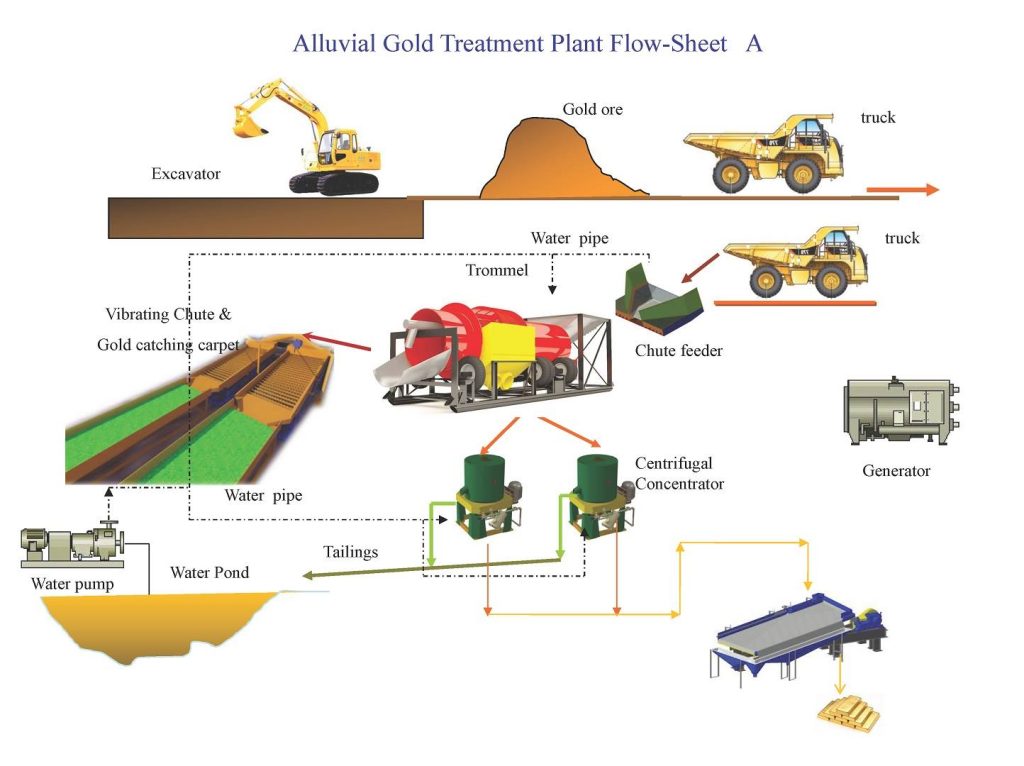

| High Clay (>20%) | Gold locked in clay | Aggressive Scrubbing is Mandatory. Hopper -> Rotary Scrubber -> Trommel Screen -> Multi-Stage Concentration (Jigs + Centrifugals). |

| Mostly Fine Gold | High loss in traditional systems | Centrifugal Concentrators are a Must. Washing/Screening -> Centrifugal Concentrator Circuit -> Shaking Table. Jigs may not be necessary. |

| Coarse “Nuggety” Gold | Easy to recover, hard to screen | Focus on Robust Roughing. Grizzly Feeder -> Trommel Screen -> Jig Circuit -> Shaking Table. A scavenger circuit may be less critical. |

| “Clean” Sand & Gravel | Easiest to process | Standard Combined Flowsheet. Hopper -> Trommel Screen -> Jig (for coarse) + Centrifugal (for fine) -> Shaking Table. |

Water is the most important reagent in your plant, and it’s free. However, using it incorrectly will ruin your recovery. The pulp density (the ratio of solids to water) is a critical operating parameter.

Poor recovery and enrichment are not bad luck; they are the result of a flawed process design. Stop thinking about individual machines and start thinking about a complete, logical system. A professional placer gold beneficiation plant follows a clear philosophy:

At ZONEDING, we are experts in process design. We have spent over 20 years engineering complete, high-efficiency solutions for placer gold mines globally. We understand that every deposit is unique. We don’t just sell equipment; we analyze your ore characteristics and design a customized placer gold processing scheme that maximizes both your recovery rate and your enrichment ratio.

Don’t gamble with your investment. Contact our engineers to design a plant that actually makes you money.

Quickly diagnose & fix common crusher & grinder issues. Our guide covers overheating, blockages, & wear with practical solutions.

View detailsEfficiency in ore processing stems from the strategic balance between crushing, drying, and grinding stages. Core equipment costs typically account for a significant portion of the total investment. Achieving the target fineness with minimal ener...

View detailsMobile crushing plants have evolved from clumsy, towable units into the highly integrated, tracked giants of today. They promise flexibility and rapid deployment, changing how countless mining and construction projects operate. However, this "plu...

View detailsTransforming raw quartz into high-purity silica sand is a very smart business move in 2026. Many investors focus only on crushing rocks into smaller pieces, but true profit comes from high purity and perfect grain shape. A specialized quartz sand...

View details