A Guide to Copper Ore Minerals & Their Dressing Methods

3692The type of copper mineral directly impacts the dressing method. Learn to identify key ores and discover the right processing techniques for each type.

View detailsSearch the whole station Crushing Equipment

I’ve seen people buy beautiful, expensive crushers that were fundamentally wrong for their rock. They bought a machine, not a solution. Choosing a crusher is not about picking the biggest or cheapest option; it’s about making a strategic decision that will define the profitability of your entire operation.

The correct rock crusher selection depends on a thorough analysis of four key factors: the physical properties of your raw material (hardness, abrasiveness), your required production capacity (tonnes per hour), the desired final product specifications (size and shape), and your operational model (stationary vs. mobile).

Before you even look at a catalog, you must understand that the rock is the boss. It tells you what it needs. This guide will walk you through the critical questions you must answer to select the right crushing equipment for your specific application, ensuring you invest in a solution that works and lasts.

You’re about to put your material through immense force. Ignoring its fundamental properties is the fastest way to destroy your machine and your budget.

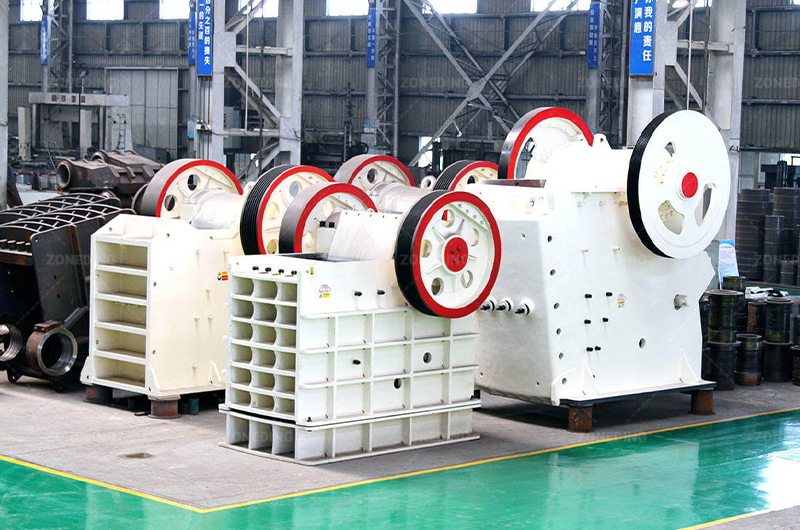

The hardness and abrasiveness of your rock are the most critical factors in how to choose a crusher. Hard, abrasive materials require compression-based machines like Jaw Crushers and Cone Crushers. Softer, less abrasive materials are better suited for Impact Crushers.

Let me be blunt: abrasiveness is the silent killer of profitability. It’s determined by the silica content of your rock. Feeding high-silica granite into an impact crusher will produce a beautiful, cubical product… for a few hours. Then you will shut down to replace the expensive blow bars. The machine will eat you alive in wear costs. Conversely, a jaw crusher uses slow, compressive force, which minimizes rubbing and dramatically extends the life of its wear parts when dealing with hard rock. Always start your selection process by understanding the rock’s personality.

| Property | Impact on Crusher Selection | Recommended Crusher Type |

|---|---|---|

| High Hardness & Abrasiveness | Causes rapid wear on impact-style crushers. Requires high compressive strength. | Jaw Crusher (Primary), Cone Crusher (Secondary/Tertiary) |

| Low Hardness & Abrasiveness | Allows for high-impact shattering, which creates better product shape. | Impact Crusher (Primary/Secondary) |

| High Clay/Moisture Content | Can cause “packing” or “pancaking” in compression chambers, stopping production. | Requires specialized feeders and may favor certain impact crusher designs. |

“Bigger is better” is a dangerous myth in the world of crushing. Your goal is a balanced and efficient system, not a single oversized machine.

Your required capacity, measured in tonnes per hour (TPH), dictates the physical size of the crusher. Your final product size requirements determine the number of crushing stages needed and the specific settings of each machine. For instance, aggregate production requires a multi-stage process from primary crushing to final shaping.

A crushing plant is a system, a handshake between machines. The output of the primary crusher must be a suitable feed for the secondary crusher. The entire circuit must be designed around your target TPH and final product gradation. Don’t forget the reduction ratio—how much smaller the crusher makes the rock in a single pass. A jaw crusher might have a 6:1 ratio, while an impact crusher can achieve over 10:1. This influences how many machines you need in your circuit. The most important specification is often the final product shape. For concrete and asphalt, a cubical, symmetrical particle is essential. Flaky, elongated particles create weak points and are often unsalable.

Each crusher is a specialist actor cast for a specific role. Using the wrong one ruins the entire production.

For primary crushing of hard rock, the Jaw Crusher is the standard. The Cone Crusher excels at secondary and tertiary crushing of hard rock. The Impact Crusher is ideal for softer rock and recycling. The VSI Sand Maker is a final-stage shaper, not a primary reducer.

Understanding the fundamental action of each machine is key to rock crusher selection. A jaw and cone use compression (squeezing), while an impact and VSI use velocity (shattering). This mechanical difference is everything.

| Crusher Type | Crushing Method | Best Application | Insider’s Secret |

|---|---|---|---|

| Soft Rock | Compression (Squeezing) | Primary crushing of hard, abrasive rock in mining and aggregate production. | A good design has an aggressive “nip angle” to reliably pull rock into the chamber without it popping back out. |

| Cone Crusher | Compression & Shearing | Secondary and tertiary crushing of hard, abrasive rock. | It performs best when “choke fed” (kept full), which promotes rock-on-rock crushing, improves shape, and protects the liners. |

| Impact Crusher | High-Velocity Impact (Shattering) | Primary/secondary crushing of soft-to-medium rock (limestone) and recycling. | It’s a velocity machine. Product shape is excellent, but wear costs on abrasive material will be extremely high. |

| VSI Sand Maker | High-Velocity Centrifugal Force | Final stage shaping for premium cubical aggregate and manufactured sand. | Using a “rock-on-rock” configuration drastically reduces wear costs when processing abrasive materials, making it a versatile finishing tool. |

The choice here is about long-term strategy versus short-term flexibility. It’s a business decision as much as an engineering one.

A stationary crushing plant represents a long-term investment for high-volume, single-site operations like a large quarry. A mobile crushing plant offers flexibility for contractors, multi-site operations, and applications like construction waste recycling.

A stationary plant has a higher initial capital cost due to concrete foundations, civil works, and extensive conveyor systems. However, it typically offers a lower operating cost per ton over its lifespan, higher capacity, and more sophisticated automation. It’s an anchor for a decades-long operation. In contrast, a mobile crusher, whether on wheels or tracks, is a self-contained unit. It can be moved to the rock face, reducing hauling costs, or transported between job sites. This flexibility is invaluable for contract crushing, road building, or pilot mining projects. Your business model—long-term producer or agile contractor—should be the primary driver of this decision.

The initial crusher price can be misleading. The true cost of a crusher is what you spend to keep it running over its lifetime.

A crusher’s long-term operating cost (OPEX) is primarily driven by three factors: the consumption of wear parts (liners, blow bars), energy (fuel or electricity), and maintenance labor. The single biggest variable affecting OPEX is the abrasiveness of your feed rock, which dictates the life of your wear parts.

Never evaluate a crusher based on its purchase price alone. A cheaper machine that consumes wear parts twice as fast will be far more expensive in the long run. When evaluating a potential machine, ask for real-world data on wear part life for a rock similar to yours. Calculate the cost of the wear parts divided by the tonnes they produce. This gives you the “wear cost per ton,” which is a far more important metric than the initial CAPEX. A well-designed crusher from a reputable manufacturer like ZONEDING is engineered to optimize crushing dynamics, which not only improves performance but also extends the life of these critical components, directly lowering your cost per ton.

Choosing the right rock crusher is a process of matching the machine to the material, the application, and the business plan. By analyzing your rock first and understanding the specific role of each crusher type, you can build a productive and profitable crushing circuit.

The type of copper mineral directly impacts the dressing method. Learn to identify key ores and discover the right processing techniques for each type.

View detailsThe selection between Direct Flotation and Reverse Flotation constitutes a fundamental engineering decision in the design of mineral processing circuits. This choice is not merely based on mineral hydrophobicity but involves a complex analysis of...

View detailsLearn correctly select stone crushers for primary, secondary, tertiary stages. Understand jaw, cone, impact, and VSI crushers for optimal aggregate production.

View detailsWith over 50 years of experience in mineral processing, ZONEDING observes that many placer gold operations lose more than 50% of their fine gold. This loss comes from technical errors in the beneficiation process, not natural causes. Purification...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy