How to Choose Stone Crusher for Each Crushing Stage

3952Learn correctly select stone crushers for primary, secondary, tertiary stages. Understand jaw, cone, impact, and VSI crushers for optimal aggregate production.

View detailsSearch the whole station Crushing Equipment

In any mineral processing plant, the grinding circuit is the heart. It is the single largest consumer of power and the primary bottleneck for production. Get it right, and your entire operation runs smoothly. Get it wrong, and you are just making expensive mud. This guide will explore the key factors affecting grinding effect and provide actionable insights to improve your grinding efficiency.

A new engineer reads a spec sheet. A veteran operator listens to the mill. It tells you exactly what it needs if you know the language. The goal is a delicate balance between three things: achieving the target particle size, maximizing throughput, and minimizing cost. Let’s break down the 5 factors that control this balance.

Before we dive into the “how,” let’s establish the “why.” The effectiveness of your grinding process is not just an operational detail; it is a primary driver of your plant’s profitability.

You cannot change your ore. Therefore, you must design your entire grinding process around its unique personality. Everything starts here.

This is the most critical number. The Bond Work Index (BWI) measures the energy (kWh/ton) required to grind an ore.

This tells you how fine you need to grind.

The composition of your ore matters.

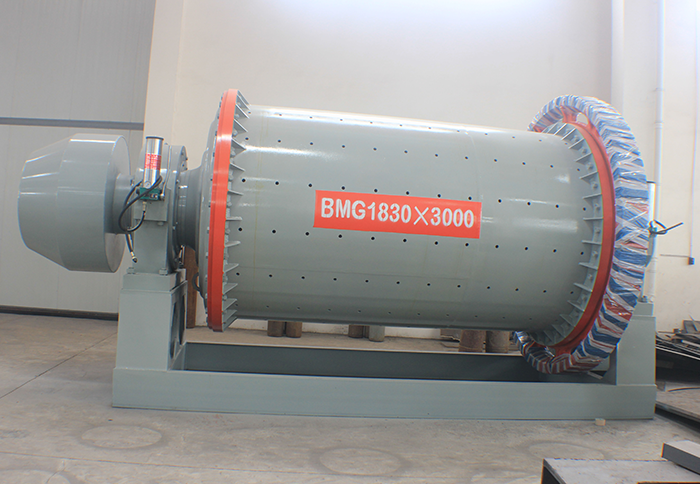

The mill itself is the core of the circuit. The right mill selection and configuration are essential for achieving high grinding efficiency.

The type and size of your mill must be matched to your ore’s BWI and your production targets. A Rod Mill is excellent for coarse grinding, while Ball Mills are the workhorses for achieving finer product sizes.

But beyond the size, the liners are critical. The steel liners inside the mill dictate how the charge is lifted and tumbles.

| Liner Profile | Grinding Action | Best For |

|---|---|---|

| Wave Liners | High abrasion, low impact | Fine grinding, secondary mills |

| Lifter Bar Liners | High impact, high cascading | Coarse grinding, primary mills |

| Rubber Liners | Lower noise, good for corrosive ores | Fine grinding where impact is less critical |

Choosing the wrong liner is like trying to drive a nail with a rubber mallet. It reduces efficiency and leads to rapid, costly wear.

The grinding media are the tools doing the work. Their management is a key part of optimizing grinding efficiency.

The size of the balls determines the grinding action.

This is the percentage of the mill’s volume filled with balls (typically 35-45%).

This is where a skilled operator makes the difference between an average plant and a highly profitable one.

This is the solids-to-water ratio and is arguably the most important operational parameter. The sweet spot is usually 65-75% solids by weight.

This is measured as a percentage of “Critical Speed” (the speed where the media centrifuges).

The rate at which new ore enters the mill must be consistent.

A grinding mill does not work in a vacuum. Its efficiency is determined by how it’s integrated into the circuit. This is such a critical factor that it deserves its own category.

For ores that require a very fine grind, a single, large mill may not be the most efficient solution.

The starting point for any new plant design or grinding process optimization is a grinding test. This is a small-scale laboratory procedure that provides the essential data needed to make multi-million-dollar decisions.

A comprehensive grinding test will determine:

Investing in a grinding test is the single best way to mitigate risk and ensure your grinding circuit is designed for maximum efficiency and profitability from day one.

Since 2004, ZONEDING has engineered robust and efficient Beneficiation Equipment for the global mining industry. We understand that grinding efficiency is the key to a profitable operation. We manufacture a complete range of Ball Mills, Rod Mills, and auxiliary equipment, and our metallurgical experts provide comprehensive grinding tests and circuit design services. We partner with our clients to deliver solutions that are not just machines, but complete, optimized systems designed to lower costs and maximize recovery.

Contact us today to discuss your grinding challenges and learn how a professional grinding test can unlock the full potential of your ore.

Learn correctly select stone crushers for primary, secondary, tertiary stages. Understand jaw, cone, impact, and VSI crushers for optimal aggregate production.

View detailsThe grinding process determines the success of mineral separation. Proper selection of grinding equipment in mining ensures a high liberation degree for mineral particles. This technical guide analyzes ball mills, rod mills, and SAG technology fo...

View detailsCopper sulfide flotation is a standard mineral processing method. However, different ore bodies require specific processing strategies due to variations in mineral composition. As high-grade deposits deplete, the industry now processes more compl...

View detailsEquipment choice impacts everything. This guide breaks down the 5 essential factors for selecting lithium ore processing equipment for optimal recovery rates.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy