Rock Crushing Machines: Your Complete Guide to Crushing

4066Discover all about rock crushing machines: types, applications, working principles, & how to choose the best one for your project. Get expert insights here!

View detailsSearch the whole station Crushing Equipment

Copper sulfide flotation is a standard mineral processing method. However, different ore bodies require specific processing strategies due to variations in mineral composition. As high-grade deposits deplete, the industry now processes more complex and low-grade copper-sulfur ores. Success depends on precise process selection and control of surface electrochemical properties. This article analyzes the technical criteria for choosing between Priority, Bulk, and Stage Grinding-Flotation processes.

Process design depends on the specific mineralogy of the ore. Different copper minerals exhibit distinct floatability characteristics.

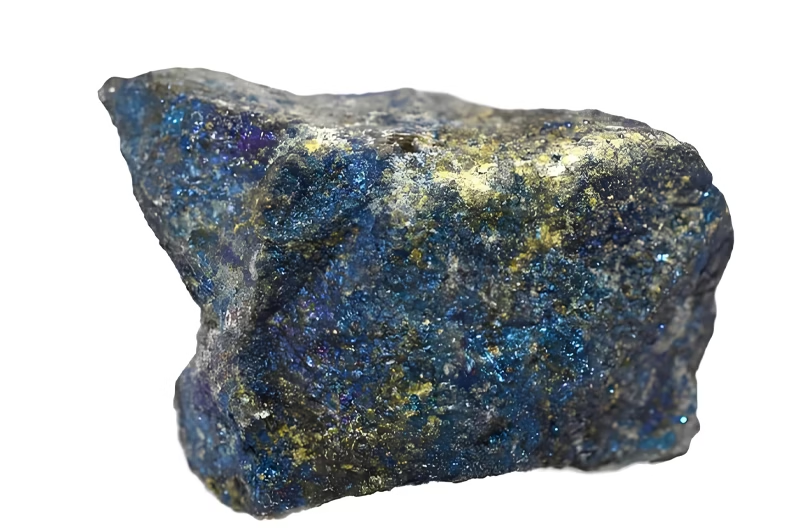

Chalcopyrite (CuFeS₂):

This is the most common primary copper mineral. It floats well with sulfhydryl collectors like xanthates. The main processing challenge is copper-sulfur separation, as chalcopyrite often co-exists with pyrite, and their flotation behaviors are similar under certain conditions.

Chalcocite (Cu₂S) and Covellite (CuS):

These are secondary copper sulfides. They have high natural floatability and float faster than chalcopyrite. However, they are brittle and easily over-ground into slime. Additionally, they release copper ions (Cu²⁺) into the pulp, which activates pyrite and complicates separation.

Bornite (Cu₅FeS₄):

Bornite often occurs with chalcopyrite. It has a fast flotation rate but is sensitive to surface oxidation.

Chemical environment and particle size distribution directly impact flotation efficiency.

Fresh sulfide surfaces are hydrophobic. However, ores from stockpiles or transition zones often develop oxide films. Standard collectors do not adsorb well onto oxidized surfaces. This reduces copper concentrate recovery.

Fine particles (slime) coat valuable mineral surfaces. This prevents collector adsorption and increases pulp viscosity. High clay content in the ore exacerbates this issue.

Technical Solutions:

For oxidized surfaces, sulfidizing agents (like NaHS) or Hydroxamic Acid collectors improve recovery. High-intensity scrubbing removes oxide layers. For high slime content, using a sulfidizing agents for desliming is an effective method.

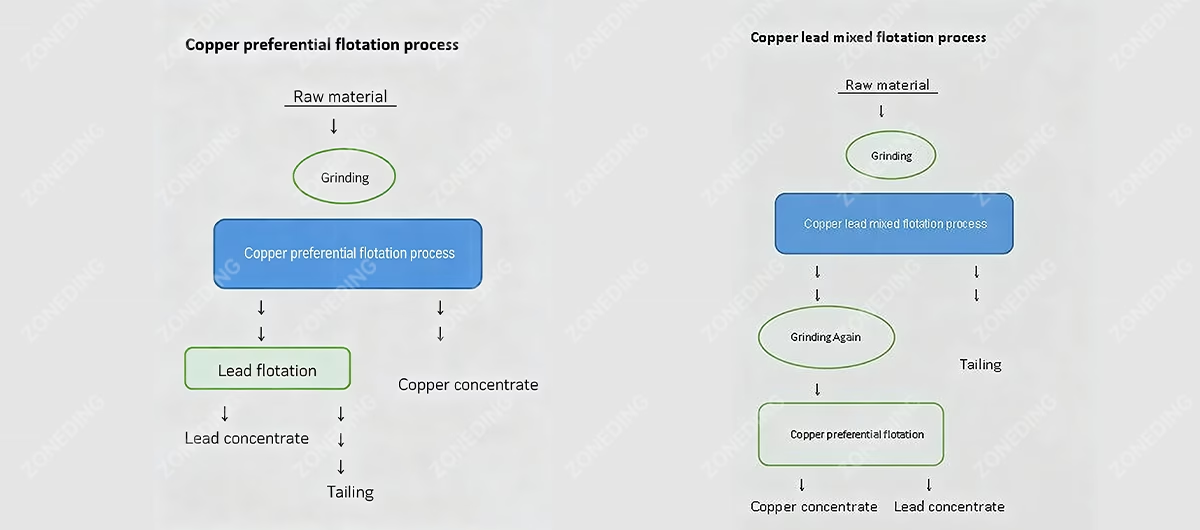

The Priority flotation process floats copper minerals first while suppressing pyrite. Pyrite is floated in a subsequent stage if it contains value.

Application Conditions:

The Bulk flotation process floats all sulfide minerals (Copper and Pyrite) together into a rougher concentrate. The tailings are discarded. Separation of Copper and Pyrite occurs in the cleaning stage.

Application Conditions:

For complex ores, grinding the entire feed to the liberation size consumes excessive energy. Stage grinding and stage flotation is the standard solution.

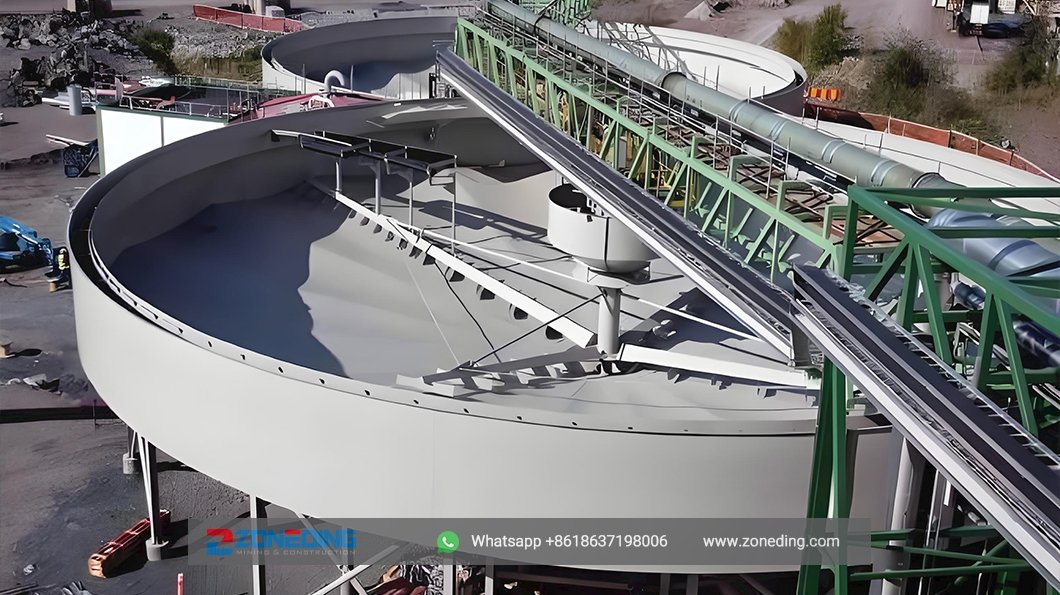

A complete copper sulfide flotation plant requires a systematic arrangement of machinery. The following list details the essential equipment manufactured by ZONEDING for this process.

The objective is to reduce Run-of-Mine (ROM) ore to a suitable feed size for grinding (typically <12mm).

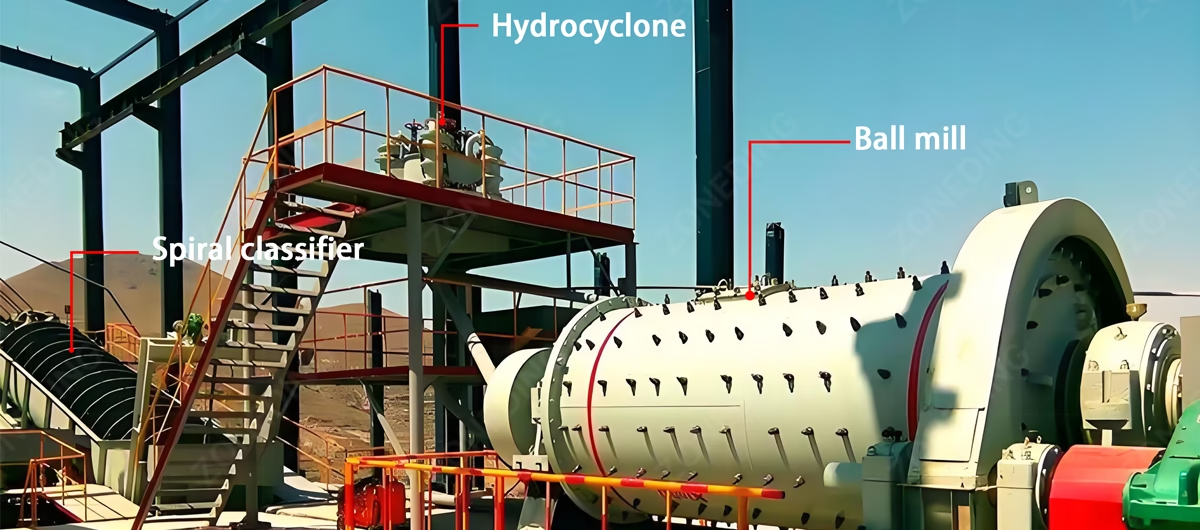

The objective is to liberate the valuable copper minerals from the gangue.

The objective is to separate hydrophobic copper minerals from hydrophilic gangue.

The objective is to remove water from the copper concentrate and tailings.

The flotation reagent regime determines the separation efficiency.

A single collector is rarely sufficient.

Steel balls release iron ions and consume oxygen during grinding. This creates a reducing environment. For difficult ores, specialized Ceramic Ball Mills prevent iron contamination, helping maintain the optimal pulp potential for chalcopyrite flotation.

Separating copper from sulfur (pyrite) is a critical step.

Pyrite Activation Mechanism:

Secondary copper minerals dissolve during grinding, releasing Cu²⁺ ions. These ions adsorb onto pyrite surfaces, activating the pyrite and causing it to float with copper.

Suppression Techniques:

Q1: Why is recovery low despite good copper concentrate grade?

Low recovery usually indicates losses in the tailings. If losses are fine particles, slime coating or over-grinding is the cause. Use a Hydrocyclone for desliming. If losses are coarse, liberation is insufficient. A Ball Mill regrind circuit is required.

Q2: How is high-pyrite copper ore processed?

Use Priority Flotation. Maintain pH between 10.5 and 11.5 with Lime to depress pyrite. If separation is poor, test for copper ion activation and consider adding Sodium Sulfide.

Q3: Can oxide and sulfide copper ores be processed together?

Simultaneous processing is difficult because reagents differ. The standard method is “Sulfide-Oxide Sequential Flotation.” Sulfides are floated first, followed by sulfidization (using NaHS) to float the oxides.

Q4: When should a flotation column be used?

Columns are effective for cleaning stages to improve concentrate grade. Mechanical Flotation Machines are generally more effective for roughing stages where recovery is the primary goal.

Q5: Does water quality affect flotation?

Yes. Recycled water accumulates ions like Calcium and Thiosulfate. Calcium ions depress Molybdenite. Water treatment or precipitation is necessary before reusing water in specific circuits.

Copper sulfide flotation requires technical management of grinding fineness, reagent chemistry, and electrochemical potential.

ZONEDING manufactures Copper Processing Plant equipment. We provide technical solutions based on mineralogical analysis. We supply Crushing Equipment, grinding mills, and flotation cells tailored to specific ore characteristics.

Contact ZONEDING for ore analysis and process design.

Discover all about rock crushing machines: types, applications, working principles, & how to choose the best one for your project. Get expert insights here!

View detailsMagnetic separation uses the differences in magnetic properties between minerals to achieve separation. Higher precision in this technical process leads to higher mineral sales profits. Success depends on selecting the correct magnetic field stre...

View detailsZONEDING recognizes that a successful manganese mining project depends entirely on an accurate process flow and precise equipment configuration. A one-size-fits-all approach often fails in the mining industry because every mineral deposit possess...

View detailsThe type of copper mineral directly impacts the dressing method. Learn to identify key ores and discover the right processing techniques for each type.

View details