What Are the 4 Main Iron Ore Beneficiation Methods?

3958Learn the four key iron ore beneficiation methods to turn low-grade ore into valuable concentrate, including magnetic, gravity, flotation, and other processes.

View detailsSearch the whole station Crushing Equipment

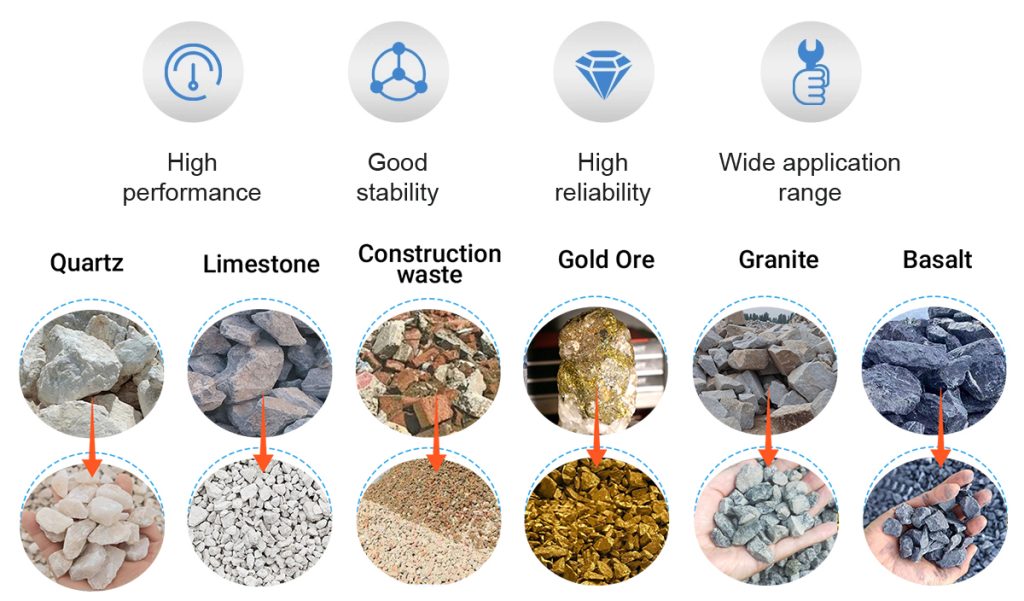

Understanding rock crusher machine technology is essential for any operation dealing with mineral processing or aggregate production. These robust machines reduce large rocks into smaller, manageable sizes. They form a core component in industries such as mining, construction, and quarrying. Choosing the correct rock crusher significantly impacts operational efficiency and profitability.

This guide explores various crushing machine types, their working principles, common applications, and critical selection factors. Insights into maintenance and emerging industry trends will also be provided. This information helps businesses optimize their crushing equipment investments.

Rock crusher machine systems are heavy-duty devices. They are designed to break down large rocks, stones, and ore into smaller pieces. This process is called crushing. Crushing alters the size and shape of raw materials. It prepares them for further processing or direct use. These machines are fundamental to mineral processing and construction industries worldwide.

Crushers apply immense force to material. This force overcomes the rock’s compressive strength. The output materials typically classify as aggregate. Aggregate finds use in concrete, roadbeds, and other construction applications. Various types of crushing machine models exist, each suited for specific tasks and material characteristics. ZONEDING provides a wide range of reliable crushing equipment for diverse industrial needs.

Selecting the correct crushing machine proves crucial for any operation. An unsuitable crusher can lead to inefficiencies, high operating costs, and poor product quality. The right choice optimizes the entire production process. It ensures maximum output with minimum energy consumption. This decision directly impacts profitability for businesses.

Factors like feed material characteristics and desired product size influence selection. Production capacity requirements also play a significant role. An appropriately chosen rock crusher handles the material effectively. It produces the specified aggregate shape and size consistently. ZONEDING’s engineering team assists clients in assessing these needs. They help identify the most suitable crushing equipment konfigurace for specific projects. This expert guidance minimizes missteps in equipment investment.

Various rock crusher types exist. Each achieves size reduction differently. Each type targets specific material characteristics and output requirements. Understanding these differences helps in selecting the optimal crushing machine. ZONEDING offers a comprehensive portfolio across these categories.

Jaw crushers serve as primary crushing equipment. They reduce large rocks and ore. These machines crush material between a fixed jaw and a movable jaw. The movable jaw applies pressure against the fixed jaw. This action breaks the rock. Jaw crushers handle extremely hard and abrasive materials. They are robust and reliable for initial size reduction. ZONEDING’s jaw crushers are known for their high capacity and durability.

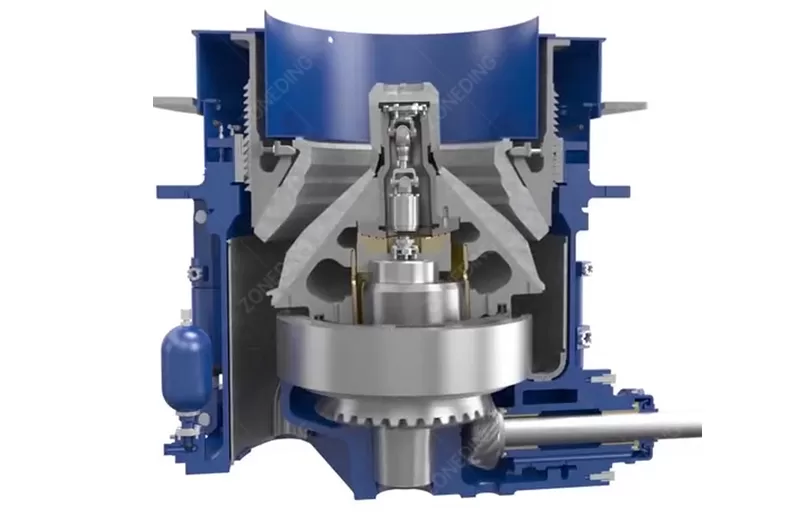

Cone crushers function as secondary or tertiary crushers. They process material already reduced by primary crushers. A cone crusher works by compressing material between an eccentrically rotating mantle and a stationary concave. This design produces a cubical product. They are suitable for medium-hard to hard materials. Cone crushers deliver high throughput and a fine output. ZONEDING offers advanced cone crushers that ensure efficient size reduction and excellent product shape.

Impact crushers utilize high-speed impact blows to shatter material. They are ideal for crushing medium-hard, non-abrasive materials. Material breaks along natural cleavage lines. This produces a cubical and well-shaped product. Impact crushers are available in horizontal shaft impact (HSI) and vertical shaft impact (VSI) configurations. VSI crushers are often used for sand making. ZONEDING’s impact crushers provide high reduction ratios and excellent product quality.

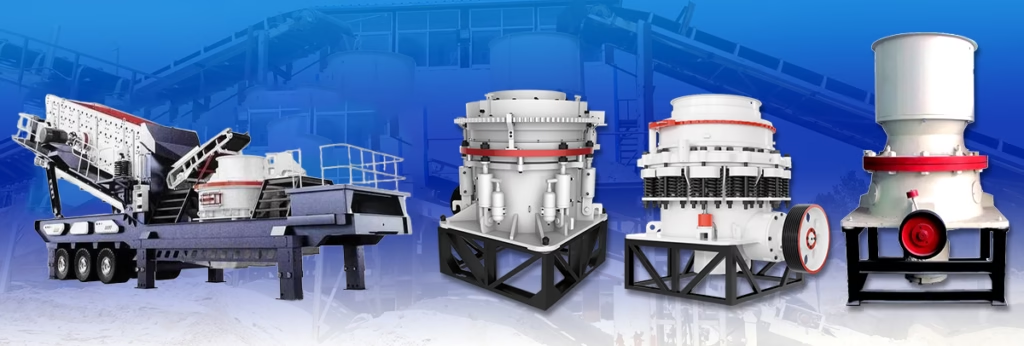

Mobile crushers integrate crushing, screening, and feeding units onto a portable chassis. These units offer flexibility and mobility. They move easily between different sites or within large operations. Mobile crushers reduce transportation costs and setup time. They are ideal for construction waste recycling and temporary quarry projects. ZONEDING’s mobile crushing plants provide versatile and efficient crushing solutions.

Understanding the working principles of rock crusher machine systems is key. It helps optimize their performance. Different crusher types employ distinct methods for size reduction. These methods vary based on force application and material characteristics.

Generally, crushing machines apply one or a combination of three forces:

Each crushing machine design optimizes these principles. This helps achieve desired product characteristics. ZONEDING designs its crushing equipment for maximum efficiency. It ensures reliable material reduction across various applications.

Rock crusher machine systems are indispensable across several major industries. Their ability to reduce large raw materials drives numerous processes. These machines are not just for basic rock breakdown. They are critical for creating specialized products.

Primary applications include:

These diverse applications highlight the versatility and importance of rock crusher machine technology.

Choosing the best rock crusher machine for a project requires careful evaluation. Many factors influence this critical decision. An informed choice leads to efficient operation and project success. This decision should involve a detailed analysis of project requirements. This serves as a vital crusher selection guide.

Consider these key factors:

ZONEDING provides comprehensive consultation services. These services help clients navigate these choices. This ensures optimal crusher selection guide for every project.

Proper maintenance is essential for extending the lifespan of any rock crusher machine. It ensures continuous, efficient operation. A rigorous maintenance schedule reduces downtime and unexpected breakdowns. These breakdowns cause significant losses in aggregate production. Implementing effective crusher maintenance tips protects your investment.

Follow these key maintenance practices:

ZONEDING offers detailed maintenance guidelines. It also provides genuine spare parts for its crushing equipment. This helps maximize operational uptime.

The rock crusher machine industry continuously evolves. Innovations aim for increased efficiency, sustainability, and intelligence. These latest trends shape the future of crushing equipment. They promise improved performance and reduced operational costs. Understanding these developments helps businesses stay competitive.

Modern crushers integrate advanced automation and control systems. These systems optimize crusher settings in real-time. They respond to changes in feed material or desired output. Features include:

Environmental concerns drive significant innovation in rock crusher design. Manufacturers focus on reducing energy consumption and minimizing environmental impact. Key advancements include:

ZONEDING incorporates these trends into its latest mining equipment. This ensures clients benefit from cutting-edge crushing machine technology.

Question 1: What is the main difference between a jaw crusher and a cone crusher?

Jaw crushers are primary crushers. They process larger, harder materials using compression between two jaws. Cone crushers are secondary or tertiary crushers. They use compression between a mantle and concave to produce finer, more cubical products.

Question 2: Can a mobile crusher be used for large-scale operations?

Yes, mobile crushers offer flexibility for large-scale operations. Modern mobile plants integrate multiple crushing and screening stages. They match the output capacity of some stationary plants. They are typically used for situations in changing mining sites or remote infrastructure projects.

Question 3: How often do wear parts need replacing on a rock crusher?

Wear part replacement frequency depends on material abrasiveness, usage hours, and maintenance quality. Abrasive materials like basalt crusher feed require more frequent changes. Regular inspections indicate when parts reach their service life.

Question 4: What are the benefits of using a VSI crusher as a sand making machine?

VSI crushers produce a cubical product. This enhances the quality of manufactured sand. They are ideal as a sand making machine. This type of sand improves concrete strength and workability, leading to higher quality construction.

Question 5: What should be considered when choosing between a new and used rock crusher?

Consider budget, project duration, maintenance history, and available spare parts. New crushers offer warranties and the latest technology. Used crushers provide cost savings. However, they may require more immediate maintenance.

Rock crusher machine systems are central to industries that process aggregates and minerals. Selecting the appropriate crushing equipment, understanding its working principles, and implementing good maintenance practices are vital. These actions ensure efficient, profitable, and sustainable operations. The continuous evolution of crushing machine technology provides exciting opportunities. These opportunities aim to enhance performance and reduce environmental impact.

Successful aggregate production and mineral processing depend on informed decisions. Partnering with experienced suppliers and investing in advanced, reliable machinery makes a significant difference. This guide provides foundational knowledge for achieving crushing success.

ZONEDING MACHINE stands as a leading crushing equipment manufacturer. It offers comprehensive solutions for rock crusher machine systems. Its extensive product line includes jaw crushers, cone crushers, impact crushers, and advanced mobile crushing plants. These machines are designed for high efficiency, durability, and customization.

ZONEDING provides full-service support. This spans from project consultation and crusher selection guide assistance to equipment manufacturing, installation, and after-sales service. With over 20 years of industry experience and global reach in 120+ countries, ZONEDING delivers proven expertise. Factory-direct sales ensure competitive pricing. This makes ZONEDING an ideal partner for achieving crushing machine operational excellence and a profitable ceramsite line.

Learn the four key iron ore beneficiation methods to turn low-grade ore into valuable concentrate, including magnetic, gravity, flotation, and other processes.

View detailsDeciding between a ball mill and a rod mill? This guide breaks down the selection criteria, from feed size to desired output, for your grinding circuit.

View detailsThe perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsHow much does a basalt crushing plant cost? This guide breaks down the price of all machines, explains the process, and helps you budget for a profitable plant.

View details