Optimizing Gold Elution: Understanding Its Advantages & Problems

3971This article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsSearch the whole station Crushing Equipment

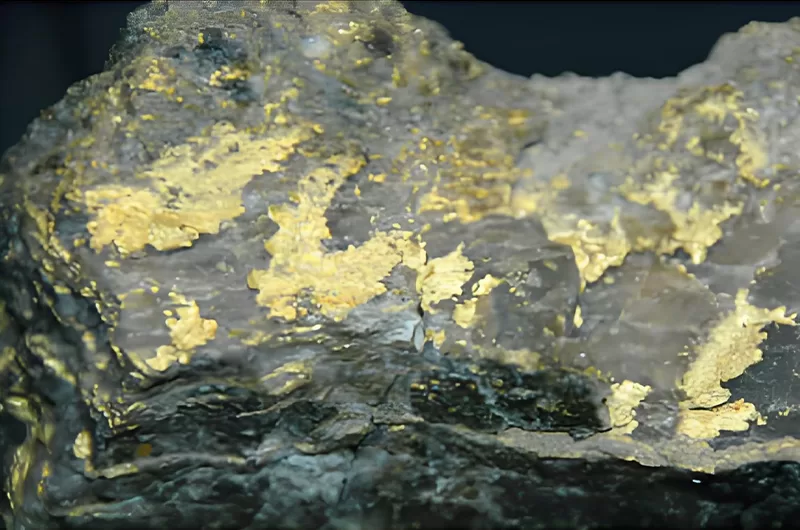

Your gold is locked inside hard rock. The challenge isn’t just breaking that rock; it’s performing a delicate surgery. Crush it too little, and you throw gold away. Crush it too much, and you turn your precious metal into unrecoverable dust. This is where fortunes are made and lost.

The optimal portable hard rock crusher for gold mining is a two-stage system, typically a primary Tracked Jaw Crusher followed by a secondary Tracked Cone Crusher. This combination provides the durability to handle abrasive ore and the precise control needed to achieve the target ore liberation size, which is essential for maximizing the gold recovery rate.

In gold mining, you are not selling crushed rock; you are selling the gold you can recover from it. Therefore, your crushing circuit is not just a rock breaker; it is the first and most critical stage of your recovery plant. Its only job is to prepare the ore perfectly for the downstream process. Let’s engineer a liberation system, not just buy a crusher.

You’ve heard that crushing is important, but why? The answer lies in a concept that directly controls how much gold ends up in your pocket.

“Ore liberation size” is the specific particle size to which rock must be crushed to expose the gold particles, freeing them from the surrounding waste rock (gangue). Hitting this target size is crucial; over-grinding creates ultra-fine gold that is easily lost, while under-crushing leaves gold locked away.

Think of it this way: your gold is like the almonds in a chocolate bar. Your goal is to break the chocolate just enough to get the almonds out whole. If you don’t break it enough, the almonds stay trapped. If you smash the whole bar into a fine powder, you’ll have a mess of chocolate and almond dust that’s impossible to separate. In gold mining, that “dust” is your profit washing away into the tailings pond. Every decision you make about your gold mining crusher must be aimed at achieving this perfect liberation size, which can only be determined by metallurgical testing of your specific ore.

| Crushing Level | Result | Impact on Gold Recovery |

|---|---|---|

| Under-Crushing | Gold remains locked within larger waste rock particles. | Low Recovery (Gold is discarded with coarse tailings) |

| Optimal Crushing | Gold particles are exposed and separated from the gangue. | Maximum Recovery (Ideal feed for gravity or leach circuits) |

| Over-Crushing | Gold is ground into microscopic, slime-like particles. | Low Recovery (Fine gold is lost in the processing slurry) |

Your primary crusher is the frontline soldier. It takes the biggest hits from the hardest, most abrasive rock. In a remote location, its reliability is non-negotiable.

A Jaw Crusher is the preferred primary crusher for hard rock gold mining. Its simple, compressive crushing action is the most cost-effective and reliable method for breaking hard, abrasive ores like gold-bearing quartz. A Tracked Jaw Crusher provides the ultimate mobility for remote sites.

An impact crusher would be a financial disaster in this role; the high-silica content of quartz ore would destroy its blow bars in hours, eating your profits in wear parts. A jaw crusher, however, is built for this fight. It squeezes the rock, minimizing the rubbing that causes rapid wear. A critical feature for any portable jaw crusher in a gold circuit is an integrated grizzly feeder. This scalps off fine material before it enters the crushing chamber, which increases throughput, reduces wear, and prevents wet, sticky ore from packing and halting your operation. It’s an essential feature that separates a professional setup from an amateur one.

The jaw crusher’s output is manageable, but it’s still too coarse for efficient recovery. The job of the secondary crusher is precision.

For secondary crushing in a hard rock gold circuit, the Cone Crusher is the ideal partner to a jaw crusher. It efficiently handles abrasive feed and offers precise control over the final product size, which is critical for achieving the target liberation size. Impact and Hammer Crushers are not suitable due to extremely high wear costs on hard ore.

A cone crusher continues the work of the jaw using compression, making it highly durable against abrasive ore. Its key advantage is the ability to “dial in” the output size by adjusting the closed-side setting (CSS). For maximum efficiency, a Tracked Cone Crusher should be configured in a “closed circuit” with an onboard screen. Material that is already small enough bypasses the crusher, while oversized material is sent back for another pass. This simple configuration is a game-changer: it prevents over-crushing, protects your gold, and produces the perfect, consistent feed for your expensive grinding and recovery circuit.

| Crusher Type | Suitability for Hard Rock Gold | Reason |

|---|---|---|

| Cone Crusher | Excellent | Handles abrasion well, offers precise size control, ideal for closed-circuit operation. |

| Impact Crusher | Extremely Poor | Catastrophic wear rates on abrasive quartz ore, leading to unsustainable operating costs. |

| Hammer Mill | Poor | Very high wear on hard rock; better suited for softer minerals or as a fine grinder after crushing. |

“Portable” can mean different things. Choosing the right platform is about matching the equipment to your site’s logistics and operational plan.

Tracked mobile units offer the best all-terrain mobility and fastest setup time, ideal for rugged, undeveloped mine sites. Wheeled units are best for operations with road access between multiple locations. Skid-mounted crushers are semi-permanent solutions that offer a balance of portability and stability but require a crane for setup.

For most small-scale or exploration gold projects, a diesel engine crusher on a tracked chassis is the clear winner. These self-contained mobile crusher plants can be driven directly to the work area via remote control, are operational within hours of arrival, and don’t require any concrete foundations or external power. This level of flexibility and rapid deployment is invaluable when you’re working against time and the elements in a remote location. ZONEDING offers a full range of these mobile solutions designed for the specific challenges of remote mining.

The purchase price of your portable rock crusher is only the beginning of the story. The true cost is revealed in your daily operating budget.

The long-term cost of a gold mining crusher is dominated by OPEX (Operating Expenses), specifically the consumption of wear parts and diesel fuel. When crushing hard, abrasive ore, the “wear cost per ton” is a more important metric than the initial purchase price of the machine.

Before buying any machine, you must demand to know the expected lifespan of the jaw plates and cone liners when crushing your type of rock. Calculate this by taking the cost of a full set of wear parts and dividing it by the number of tons they are expected to process. A cheaper machine that requires a new set of liners every 20,000 tons will be far more expensive than a robustly built machine whose liners last for 80,000 tons. This calculation, combined with fuel consumption data, will reveal the true cost of owning and operating the equipment—and its ultimate impact on the profitability of your gold mine.

The right portable hard rock crusher for gold mining is a complete liberation system. A two-stage tracked jaw and cone crusher circuit gives you the power to break hard rock and the precision to protect your gold, maximizing recovery and ensuring your remote operation is profitable.

This article explains the gold elution process. Understand its main advantages, typical problems that can arise, and how to solve them for better performance.

View detailsIt's easy to mistake pyrite for gold. This guide shows you a simple streak test and other quick checks anyone can perform to identify fool's gold.

View detailsA detailed explanation of a lead-zinc ore processing line. Understand the science of preferential flotation to separate lead (galena) and zinc concentrates.

View detailsReduce costly downtime and extend the service life of your ball mill liners. Discover 5 expert solutions to diagnose and fix the root causes of rapid wear.

View details