Gold Cyanidation: From Process Types to Plant Construction

3750Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsSearch the whole station Crushing Equipment

Operating an iron ore beneficiation plant profitably is a constant challenge. You face rising energy costs, lower-grade raw materials, and strict environmental regulations. An inefficient process allows profit to drain away at every stage. We must move beyond a simple “crush, grind, separate” mentality and adopt a systematic approach to efficiency.

Efficient iron ore processing is a five-step system: 1. Optimize crushing and grinding to reduce energy. 2. Use precise screening and classification to control particle size. 3. Select the correct separation method based on ore mineralogy. 4. Dewater concentrate to recover water and reduce transport costs. 5. Manage tailings to ensure compliance and find value.

This guide is not a textbook summary. It is a strategic framework based on field experience. I will explain how to optimize each of these five critical stages. The goal is to maximize the iron ore grade and recovery rate while minimizing the cost per ton. This is how a modern plant achieves maximum profitability.

Comminution, the combined process of crushing and grinding, is the single largest consumer of energy in a plant, often accounting for 50-70% of total power usage. Inefficiency here is a direct and continuous financial loss.

To optimize comminution, you must apply the principle of “more crushing, less grinding.” This involves using multiple, efficient crushing stages to produce a finer feed for the grinding mills. This strategy significantly reduces the overall energy required because crushers are more energy-efficient than mills.

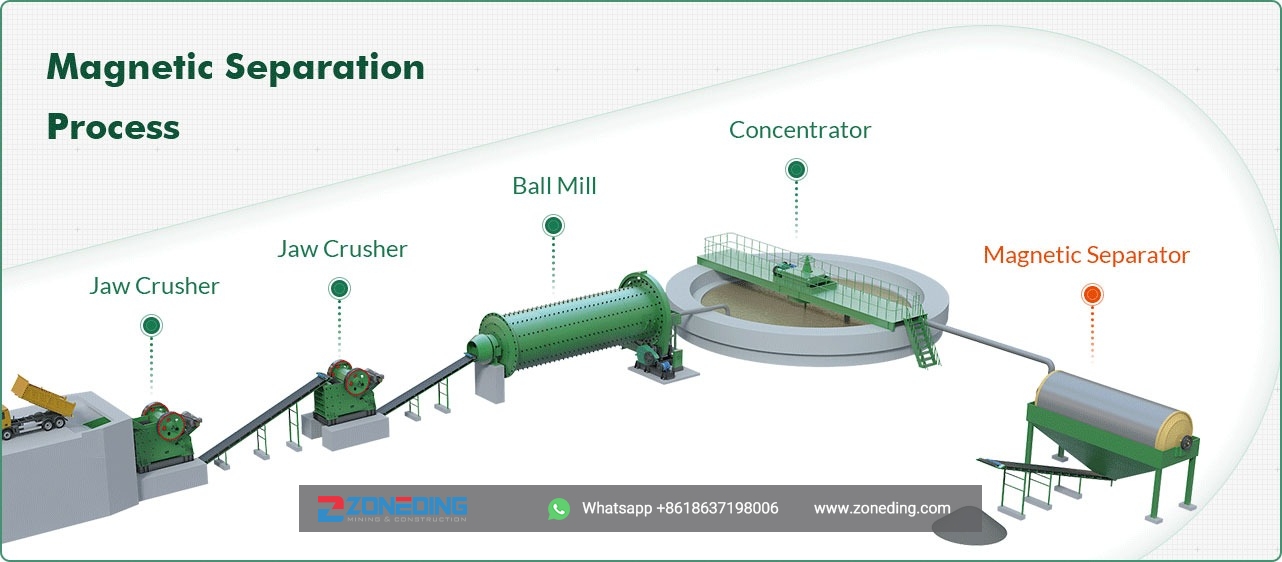

The process starts before the first crusher. A well-managed coarse ore stockpile acts as a homogenizing buffer. Blending different ore types creates a consistent feed, allowing the entire plant to operate at a stable, optimal level. For some magnetic ores, early rejection of waste rock using a dry magnetic cobbing separator after primary crushing can remove a significant portion of barren material before you spend any energy grinding it. The core strategy is to use a multi-stage crushing plant, typically with a primary Jaw Crusher followed by secondary and tertiary Cone Crushers. The objective is to make the feed to the Ball Mills as fine as is economically practical. Advanced technologies like High-Pressure Grinding Rolls (HPGR) can further reduce energy consumption by 20-40% compared to conventional mills by using highly efficient inter-particle compression.

Incorrectly sized particles are a major source of inefficiency. Coarse particles that escape grinding lead to lost iron in the tailings. Fine particles that are ground repeatedly waste energy and can create “slimes” that hinder separation.

Precise screening in the crushing circuit and classification in the grinding circuit are essential for particle size control. These processes ensure that material is crushed or ground only to the necessary liberation size, preventing both energy waste from over-grinding and metal loss from under-grinding.

In the crushing stages, Vibrating Screens are used in a closed circuit with the cone crushers. The screen separates the crusher’s output. Material that is already at the target size is sent to the next stage. Oversized material is returned to the crusher for another pass. This ensures a consistent product size is fed to the grinding circuit. In the grinding circuit, which is a wet process, Hydrocyclones or Spiral Classifiers perform a similar function. They work in a closed loop with the ball mill. The classifier separates the mill discharge by size. The fine overflow, which has reached the target liberation size, is sent to the separation stage. The coarse underflow is returned to the ball mill for further grinding. This precise control is fundamental to the entire plant’s efficiency.

There is no single “best” method for iron ore beneficiation. The choice of technology is dictated entirely by the mineralogy of the ore. Using the wrong method will result in poor separation, low recovery, and financial failure.

he most efficient method depends on whether the primary iron mineral is magnetite or hematite. Strongly magnetic magnetite is best processed using cost-effective Low-Intensity Magnetic Separation. Weakly magnetic hematite requires different methods, such as Gravity Separation or high-intensity magnetic separation.

| Ore Type | Key Mineral | Magnetic Property | Primary Beneficiation Method |

|---|---|---|---|

| Magnetite Ore | Magnetite (Fe₃O₄) | Strongly Ferromagnetic | Low-Intensity Magnetic Separation (LIMS) |

| Hematite Ore | Hematite (Fe₂O₃) | Weakly Paramagnetic | Gravity Separation (Spirals, Shaking Tables) |

| Mixed Ores | Magnetite/Hematite | Mixed | Combination of LIMS and Gravity/High-Intensity Separation |

For magnetite processing, a multi-stage circuit using LIMS drums is standard. This circuit consists of Roughers (to maximize recovery), Cleaners (to maximize grade), and Scavengers (to recover any iron missed by the roughers). This approach ensures both a high-grade final product and a high overall metal recovery rate. For hematite, gravity methods are common. Spiral Chutes make a bulk separation of the heavy iron minerals from the lighter gangue (like silica). This can be followed by further cleaning on Shaking Tables. For complex or very fine-grained ores, more advanced techniques like high-intensity magnetic separation or even Flotation may be necessary.

After separation, the valuable iron concentrate is a dilute slurry containing a large amount of water. This water is a valuable resource that must be recycled. Also, shipping a product with high moisture content means paying to transport water, which is a direct financial loss.

Efficient dewatering is a two-step process. First, a thickener recovers the majority of the process water for immediate reuse. Second, filters mechanically remove the remaining water to produce a final concentrate with a low moisture content suitable for transport.

The first and most important dewatering unit is the High Efficiency Concentrator, or thickener. This large tank allows the solid particles to settle by gravity. The clear water overflows the top and is immediately pumped back into the mineral processing circuit. This step alone can achieve over 90% water recycling, drastically reducing the plant’s need for fresh water. The thickened underflow from the thickener, which has a much higher solids density, is then pumped to the filtration stage. Here, vacuum or pressure filters are used to mechanically force out more water, producing a final filter cake with a target moisture of 8-10%. This minimizes product weight for shipping and prevents issues like freezing during transport.

Tailings, the waste product of beneficiation, are the largest volume output of a mining operation. Managing them safely and responsibly is a critical component of a modern, efficient plant. It is no longer acceptable to simply view tailings as waste.

Modern tailings management focuses on maximizing water recovery and creating a physically stable material. This is achieved through dewatering the tailings using thickeners and filters, which minimizes the size of the storage facility and reduces environmental risk. It also presents opportunities to use the tailings as a resource.

The same dewatering technology used for the concentrate can be applied to the tailings stream. A tailings thickener recovers process water that would otherwise be lost to the tailings pond. For operations in arid regions or with very strict regulations, tailings can be further dewatered using filters to produce a “dry cake.” This filtered tailings material can be conveyed and stacked (a practice known as dry stacking), which creates a much smaller and more stable landform than a conventional dam. Furthermore, dewatered tailings can be mixed with cement to create a paste, which can be pumped underground to backfill mined-out voids. This practice, known as paste backfill, improves ground stability and reduces the amount of waste that needs to be stored on the surface.

An efficient iron ore processing plant is an integrated system. By systematically optimizing comminution, classification, separation, dewatering, and tailings management, you can significantly lower your operating costs, maximize the value of your resource, and ensure the long-term sustainability and profitability of your operation.

Your ultimate guide to gold cyanidation. Explore CIL/CIP types, detailed processes, and the complete steps for successful plant construction and optimization.

View detailsProcessing materials with an represents a high-profit strategy for aggregate production. However, selecting the wrong material leads to astronomical wear costs and frequent downtime. High hardness materials can destroy expensive wear parts in hou...

View detailsIn the gold mining industry, carbonaceous gold ore is known as the "Silent Thief." High gold grades may appear in geological reports, yet recovery rates can plummet below 30% due to the dreaded preg-robbing effect. The natural organic carbon in t...

View detailsOptimize ball mill performance, minimize downtime, and extend lifespan by mastering operation, key maintenance, and problem analysis.

View details