How to Select the Right Mineral Grinding Mill? A Practical Framework

3570This expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View detailsSearch the whole station Crushing Equipment

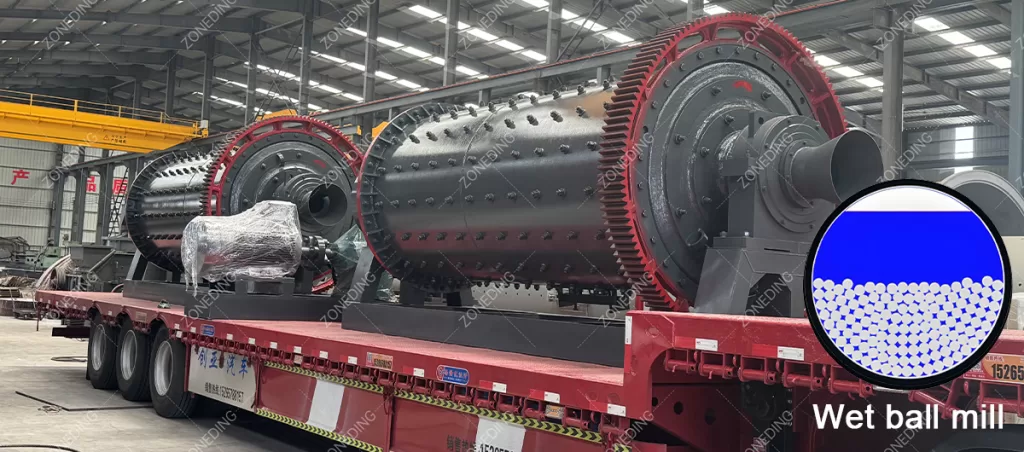

As manufacturers of industrial grinding mills, we often get a fundamental question: “Should I choose a dry ball mill or a wet ball mill?” The answer is not about preference; it is about the physics of your material and the economics of your entire operation. Choosing the wrong method can lead to massive inefficiencies, higher operating costs, and even complete process failure. The presence of water transforms the grinding environment entirely, impacting everything from energy use to the type of downstream equipment you need. This guide will explain the critical differences to help you make the right ball mill selection.

Under the same mill size and power, a Wet Ball Mill typically has higher production efficiency and better grinding results. The primary reason is material transport. In wet grinding, water creates a slurry that continuously carries fine, finished particles out of the mill. This action constantly exposes coarser particles to the direct impact of the grinding media (the steel balls). The process is fluid and continuous, ensuring energy is spent on breaking new material.

In a Dry Ball Mill, there is no transport medium. Finely ground particles do not exit the mill easily. They tend to cling to the liners and grinding media due to static forces and residual moisture. This creates a “cushioning” effect where the steel balls waste energy impacting a layer of fine powder instead of the coarse particles you want to break. This phenomenon, known as over-grinding, severely reduces efficiency. To compensate, a dry grinding circuit requires a complex air-swept system to pull the fines out, which consumes additional energy and is less effective than the simple slurry flow in a wet mill.

The difference is not minor. For the same material and target fineness, a wet ball mill can be 15-30% more energy-efficient than a dry mill of the same dimensions. This translates directly into lower electricity costs per ton of product. Furthermore, because of this efficiency, a wet mill generally has a higher throughput (tons per hour) than a dry mill of the exact same size. This means you might be able to use a smaller, less expensive wet mill to achieve the same production target as a larger dry mill, reducing your initial capital investment.

The dust generated by a Dry Ball Mill is not just a housekeeping issue; it is a major operational, safety, and financial challenge. You are essentially creating a self-contained dust storm inside a steel drum. This requires an expensive and power-hungry auxiliary system to manage. This system typically includes high-volume fans, ducting, cyclones, and a large baghouse filter to capture the fine particles.

This dust control system is a factory within your factory. It requires constant maintenance, from replacing clogged filter bags to managing the collected dust. More critically, many materials create explosive dust when suspended in air, such as coal or sulfide ores. This requires expensive explosion-proof motors, sensors, and fire suppression systems. Fine silica dust is also a known cause of silicosis, a severe occupational lung disease, making robust dust control a legal and ethical necessity. In contrast, a wet grinding circuit has virtually no dust. The material is contained within a slurry from the mill to the next process step.

Yes, in almost all cases. Your downstream process is often the deciding factor in the dry vs. wet grinding debate. If your next step is a hydrometallurgical process—one that takes place in water—then a wet ball mill is the only logical choice.

Yes, the operating environment significantly affects the wear and consumption of grinding media (steel balls). Dry grinding is a hotter, more abrasive environment. With no water to dissipate heat, the temperature inside a dry mill can rise significantly. This heat can reduce the hardness and toughness of the steel balls, accelerating wear. The dry, abrasive particles also cause higher rates of wear on both the balls and the mill liners.

In a wet ball mill, the water slurry acts as a coolant and a lubricant. It keeps temperatures stable and reduces friction between the media, liners, and ore particles. As a result, the consumption rate of steel balls and liners in a dry grinding circuit can be 2 to 4 times higher than in a wet circuit processing the same material. This means higher operating costs for consumables and more frequent downtime for adding media and replacing worn liners.

| Parameter | Wet Ball Mill | Dry Ball Mill | Your Key Takeaway |

|---|---|---|---|

| Energy Efficiency | High (15-30% better) | Low | Wet grinding lowers your electricity bill per ton. |

| Capital Cost | Lower (for a given capacity) | Higher (larger mill + dust control) | A dry grinding system is a bigger initial investment. |

| Operating Cost | Lower (less media/liner wear) | Higher (more consumables, dust control) | Dry grinding has higher lifetime costs. |

| Dust Problem | None | Severe (requires major system) | Wet grinding is cleaner and safer. |

| Water Requirement | High | Low / None | Dry grinding is essential in water-scarce regions. |

| Downstream Fit | Flotation, Leaching, Wet Separation | Cement, Dry Powders, Ceramics | Your final product dictates the choice. |

The choice between a Dry Ball Mill and a Wet Ball Mill is a strategic decision based on three main factors. Ask yourself these questions:

Q1: Can a wet ball mill be converted to a dry ball mill?

A: No, not practically. A wet ball mill is designed for overflow or grate discharge of a slurry. A dry ball mill requires a completely different discharge mechanism, often with air classification systems built in, and different bearing seals to handle fine, abrasive dust. They are fundamentally different machines.

Q2: What about materials that are sensitive to moisture?

A: If your raw material is very sensitive to moisture and tends to cake or agglomerate (like some clays), dry grinding becomes very difficult. Even a small amount of moisture can cause the material to “pancake” onto the liners and media, stopping the grinding action. In these cases, the material may need to be pre-dried in a Rotary Dryer before being fed to the dry mill.

Q3: Is there an option for “semi-wet” or “damp” grinding?

A: Generally, no. Grinding mills operate best in one of two states: fully dry (typically <1% moisture) or as a fluid slurry (typically 60-75% solids by weight). The in-between “damp” state is the worst for efficiency, as it promotes caking and agglomeration without providing the transport benefits of a full slurry.

The dry vs. wet grinding decision is fundamental. For the vast majority of mineral processing applications that lead to flotation, magnetic separation, or leaching, the wet ball mill is the superior choice. It offers higher efficiency, lower energy consumption, lower consumable wear, and a simpler, dust-free operating environment.

A Dry Ball Mill is a specialized machine reserved for specific industries where the presence of water is unacceptable, such as cement and dry powder manufacturing. While necessary in these niches, it comes with the trade-offs of lower efficiency, higher capital and operating costs, and the significant challenge of dust management.

Since 2004, ZONEDING MACHINE has been a leading manufacturer of grinding solutions for the global mining and industrial sectors. We design and build both wet and dry Ball Mills, and our engineers can help you analyze your specific process to make the optimal ball mill selection. We have delivered reliable equipment to over 120 countries.

Ready to discuss the specific needs of your grinding circuit? Contact our technical team for a professional consultation and a customized quote.

This expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View detailsTroubleshoot & resolve breakage issues in four critical ball mill parts during operation. Our guide provides solutions to keep your mill running efficiently.

View detailsWith extensive experience in the field of gold metallurgy and mineral processing engineering, ZONEDING often observes mining operations lose gold not because of poor chemistry, but due to poor carbon management. The Carbon-In-Pulp (CIP) process a...

View detailsQuickly diagnose & fix common crusher & grinder issues. Our guide covers overheating, blockages, & wear with practical solutions.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy