Jaw Crusher: A Guide to Structure, Principle & Project Selection

3987This article provides a clear look at the jaw crusher: its primary function, the simple yet powerful design, and why it's a staple in primary crushing stages.

View detailsSearch the whole station Crushing Equipment

Vast tailings dams represent a significant environmental liability and a potential safety risk for mining operations. They lock up land, water, and potentially valuable unrecovered minerals, posing a long-term management challenge.

Tailings recycling is the process of reprocessing mine waste to recover residual valuable minerals and transform the bulk material into usable products. This practice turns an environmental liability into a potential revenue stream, promoting sustainable mining.

This approach, often called secondary resource recovery, is a key component of the circular economy in the mining sector. It not only extracts additional value but also reduces the long-term environmental footprint of a mining operation, addressing both economic and ESG (Environmental, Social, and Governance) goals.

Old tailings dams are often viewed as homogenous piles of waste. This perspective overlooks the fact that they are complex, man-made deposits with varying compositions, reflecting decades of mining and processing history.

Tailings can contain a variety of valuable metals that were not efficiently recovered during the initial processing. These often include precious metals like gold and silver, base metals such as copper and tin, and other minerals that have become economically viable with new technology.

Viewing a tailings dam as a primary orebody is the correct approach. It is not a uniform pile but a geochemical layer cake, with each layer possessing a different mineralogy, particle size, and grade.

A thorough analysis is required to understand the potential of a tailings facility. Assuming an “average” grade based on a few surface samples is a common and costly mistake.

Reprocessing tailings is not as simple as running them through the original plant again. The material has unique properties that require a specialized equipment flowsheet to be handled efficiently.

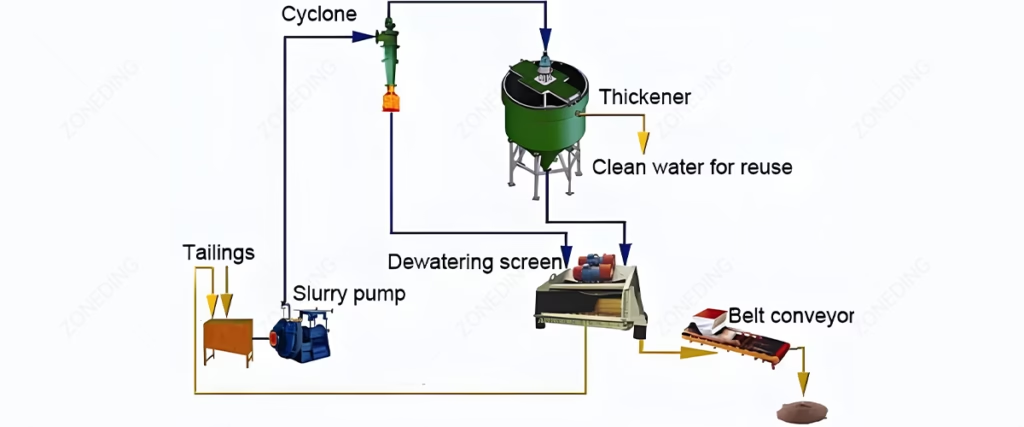

Core equipment for tailings reprocessing includes slurry pumps for hydraulic mining, Hydrocyclones for de-sliming, small Ball Mills for regrinding, specialized separation equipment like Flotation Machines or gravity separators, and dewatering units like Thickeners.

The most critical step in this process is the effective removal of ultra-fine clay and silicate particles, known as slimes.

Slimes are the primary enemy of efficient tailings reprocessing and can ruin a project’s economics if not managed correctly.

Why Slimes Are Problematic:

The De-sliming Circuit: The first stage after slurrying the tailings must be a dedicated de-sliming circuit. This typically uses multiple stages of Hydrocyclones to wash the feed and split it into two streams: a clean sand underflow that proceeds to the recovery plant, and a slime overflow that is sent directly for disposal or thickening. Investing in an efficient de-sliming circuit significantly reduces operating costs and improves overall recovery.

Storing vast quantities of tailings in dams poses long-term risks. These facilities require perpetual management and represent a potential source of environmental contamination and catastrophic failure.

Tailings recycling is necessary to mitigate environmental risks, ensure dam safety, and recover valuable resources that would otherwise be lost. It is a fundamental component of sustainable mining, turning a long-term liability into a productive asset.

The drivers for tailings reprocessing are both environmental and economic. As high-grade primary ores become scarcer, these secondary resources become increasingly attractive.

Recovering residual metal is often only part of the economic equation. The bulk material of the tailings, primarily sand and fine aggregates, has significant value if processed correctly.

Beyond mineral recovery, recycled tailings are primarily used as construction aggregates, manufactured sand for concrete, and as paste backfill for underground mines. This creates a stable, high-volume revenue stream independent of volatile metal prices.

Shifting the business model from “mining metal” to “manufacturing aggregates with a metal credit” fundamentally de-risks a tailings project.

The primary product from most tailings reprocessing projects is not metal, but industrial minerals.

| Application | Description | Market |

|---|---|---|

| Construction Aggregates | Washed and classified sand and gravel for building and road base. | Local Construction, Infrastructure Projects |

| Mine Backfill | Mixed with cement to create paste for filling underground voids. | The mining operation itself |

| Brick and Tile Manufacturing | The fine material can be used as a component in manufacturing bricks and ceramics. | Building Materials Industry |

| Mineral Recovery | Extraction of residual valuable metals like gold, copper, iron, etc. | Global Commodity Markets |

The choice of recovery method depends entirely on the mineralogy of the tailings and their chemical history. The material is not just ground rock; it is a product of a previous chemical process.

Common recovery methods include flotation to recover sulfide minerals, gravity separation for dense minerals, and leaching for precious metals like gold. A crucial preliminary step involves metallurgical analysis to counteract residual reagents from the original process.

These “chemical ghosts” can interfere with new recovery processes, leading to poor results if not properly understood and addressed.

Before designing a plant, detailed lab work is essential to understand the chemical coatings on the mineral particles.

Underground mining creates large empty voids (stopes) that must be filled to ensure ground stability. This backfill material is a major operational cost.

Using tailings to create paste backfill can save a mine significant costs by replacing two expensive components: quarried aggregate and a large portion of the cement binder. This can reduce backfill material costs by 50-70% or more.

This practice, known as paste backfill, is a prime example of a circular economy within a single mining operation.

Paste backfill is an engineered mixture of tailings, water, and a binder (usually cement).

A mine can save millions of dollars annually by replacing purchased aggregate and reducing cement consumption through the implementation of a paste backfill system.

Conventional tailings dams, which store tailings as a wet slurry, are a source of significant risk and long-term cost. Water management is complex, and the risk of dam failure is ever-present.

Transitioning to dry stacking, where tailings are dewatered into a solid “cake” before being transported and compacted, drastically reduces risk. This method recovers most process water, creates a geotechnically stable landform, and minimizes the overall environmental footprint.

This approach moves tailings management from a perpetual liability to a structured earthworks project.

Dry stacking involves a mechanical dewatering process to remove the vast majority of water from the tailings slurry.

Investors need to know the financial viability of a project. Tailings reprocessing is not a simple venture; it requires significant capital investment and careful operational planning.

The return on investment (ROI) for a tailings project typically ranges from 3 to 7 years. The exact timeframe depends heavily on the grade of recoverable minerals, the market value of the bulk material as aggregate, capital expenditure, and operational efficiency.

Several factors influence the speed of the payback period.

A successful project balances capital costs with robust and diversified revenue streams.

A project with both strong metal recovery and a solid market for its aggregate product will see the fastest and most reliable return on investment.

Tailings recycling transforms mine waste from a liability into a valuable asset. This sustainable approach reduces environmental risk, conserves resources, and creates new, stable revenue streams for the mining industry.

This article provides a clear look at the jaw crusher: its primary function, the simple yet powerful design, and why it's a staple in primary crushing stages.

View detailsThe cone crusher represents a high-precision instrument within any Crushing Plant. Unlike equipment that relies on simple compressive force, the cone crusher operates through exact eccentric rotation and requires tight tolerance management. Prema...

View detailsCompare the top 4 gold extraction processes for oxidized ore. We analyze CIL/CIP, heap leaching, flotation & more on cost, efficiency, and application.

View detailsLearn the step-by-step process for gold extraction from oxidized ore. We define this mine type and list the key equipment for each stage of the operation.

View details