Lead-Zinc Processing: A Guide to Profitable Ore Beneficiation

3661Discover the key methods for lead-zinc ore beneficiation. This article explains how to use gravity and froth flotation to effectively separate minerals.

View detailsSearch the whole station Crushing Equipment

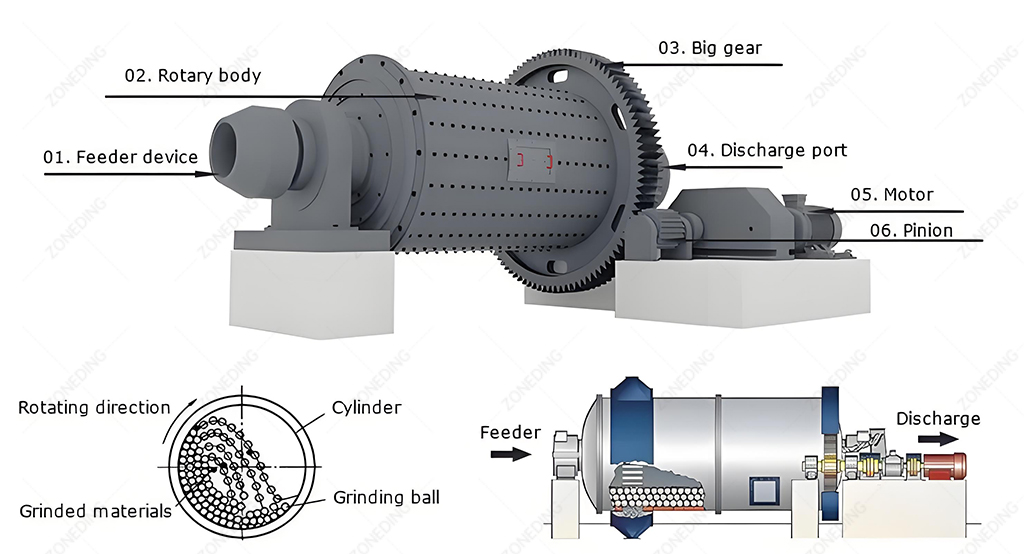

Rapid wear of Ball Mill liners is a significant operational issue, leading to increased maintenance costs, prolonged downtime, and reduced grinding efficiency. This hidden expense directly impacts the profitability of mineral processing operations.

The primary causes of accelerated liner wear are a mismatch between the liner material and the operating conditions, incorrect operational parameters like mill speed and slurry density, an improperly sized grinding media charge, and poor installation procedures.

The interaction between the grinding media (steel balls) and the liners is the fundamental mechanism of both grinding and wear. An imbalanced relationship between these two components is a primary source of accelerated liner damage.

If the grinding balls are too small for the liner profile, they can get trapped between the lifter bars. This causes them to slide against the liner plate instead of participating in the grinding action, rapidly machining the liner away.

This phenomenon, sometimes called “pulp racing” or “grinding the shell,” is extremely destructive. It concentrates wear on the flat plate of the liner while the lifter bar remains relatively intact, leading to premature failure and the wasteful disposal of partially used steel.

The solution lies in maintaining a balanced “diet” for the mill. This involves both the size of the grinding media and the total volume of the charge inside the mill.

| Factor | Problem | Solution |

|---|---|---|

| Grinding Ball Size | Balls are too small and become trapped, causing abrasive wear on the liner plate. | The top size of the grinding media must be selected based on the ore feed size (F80) and mill diameter. A proper charge consists of a balanced distribution of ball sizes. |

| Charge Volume | A low ball charge level (e.g., below 35% of mill volume) increases direct ball-on-liner and liner-on-liner contact. | Maintain the charge volume within the optimal range of 40-45%. This is achieved through regular, small additions of new balls rather than infrequent, large additions. |

| Liner Profile | As lifters wear down, their ability to lift the charge diminishes, leading to more sliding (abrasion) and less impacting (comminution). | Monitor liner wear profiles, not just thickness. Replace liners when the lifter profile is no longer effective, even if the plate has remaining thickness. |

Treating liners as a simple commodity and ordering based only on price is a common but costly mistake. The liner material must be specifically chosen to withstand the unique wear environment inside a particular mill.

Using the wrong type of steel alloy for the application leads to premature failure. Hard, brittle alloys will shatter under high impact, while tough, ductile alloys will wear away quickly in high-abrasion environments.

There is a critical trade-off between a material’s hardness (resistance to abrasion) and its toughness (resistance to cracking and impact). Selecting the wrong one for the job guarantees a short service life.

The key is to identify the dominant wear mechanism inside the mill—is it high-impact or high-abrasion?

Even when the correct steel alloy is specified, inconsistent performance can occur. A liner that cracks prematurely or wears out in half the expected time may be a result of a poorly controlled manufacturing process.

An improper heat treatment process compromises the liner’s mechanical properties. It can fail to achieve the target hardness or create internal stresses that make the liner brittle, leading to cracking and spalling in service.

Heat treatment, which involves controlled heating (quenching) and cooling (tempering), is what unlocks the desired properties of the steel alloy. Without it, the casting is just a piece of metal with unrealized potential.

A faulty heat treatment can lead to several metallurgical defects that directly impact liner performance.

| Defect | Cause | Consequence |

|---|---|---|

| Low Hardness | Insufficient quenching temperature or speed. | The liner is too soft and will experience rapid abrasive wear. |

| Brittleness / Cracking | Quenching is too aggressive, or the tempering step is inadequate. | The liner has high internal stresses and is prone to cracking under operational impacts. |

| Inconsistent Properties | Uneven heating or cooling in the furnace. | The liner has hard and soft spots, leading to unpredictable and uneven wear patterns. |

To ensure consistent and reliable liner performance, it is crucial to partner with a manufacturer that demonstrates strict quality control over its entire foundry and heat treatment process. Requesting quality assurance documentation, such as hardness test results and certificates of conformity for each batch, is a vital part of procurement.

Operational parameters have a direct and profound impact on liner wear rates. Pushing for higher throughput by simply increasing mill speed can have severe, unintended consequences on consumable costs.

Operating the mill above its optimal speed causes the charge to “cataract,” flinging media directly at the liners. This high-velocity impact drastically accelerates wear. Similarly, an incorrect slurry density can increase abrasive wear.

A Ball Mill functions most efficiently when the charge is lifted by the liners and tumbles back onto itself in a cascading motion. This maximizes particle-on-particle grinding.

Catastrophic liner failures, such as large cracks or sheared bolts, are often not a material defect. Instead, they are frequently the result of an abnormal operating condition or, most commonly, an incorrect installation procedure.

The most common cause of premature liner cracking is improper installation. If liners are not securely clamped to the mill shell, they can flex and hammer against it with each rotation, leading to fatigue failure of the liner or its bolts.

This small movement, repeated millions of times, creates immense stress. This process, known as “peening,” can cause the liner to fail long before its wear life is reached.

Preventing installation-related failures requires a fanatical devotion to correct procedure. There are no shortcuts.

| Step | Action | Why It’s Critical |

|---|---|---|

| 1. Shell Preparation | Scrupulously clean the mill shell surface where the liner will sit. | Any debris creates a high spot, leaving a void that allows the liner to flex. |

| 2. Backing Material | Use the correct rubber or epoxy backing material as specified by the manufacturer. | This material fills any remaining voids, ensuring the liner is evenly supported against the shell. |

| 3. Torque Procedure | Use a calibrated torque wrench and follow the specified multi-pass, star-pattern tightening sequence. | This ensures even clamping force across the entire liner, preventing localized stress points. |

| 4. Re-Torque | After 24-48 hours of operation, stop the mill and re-torque every single liner bolt. | This is the most critical and most often skipped step. The initial operation will compact the backing material, causing the bolts to loosen. Re-torquing is essential to guarantee the final clamping force. |

Extending Ball Mill liner life requires a holistic approach. It involves selecting the right materials, optimizing operational parameters like speed and density, using the correct grinding media, and adhering strictly to proper installation procedures.

Discover the key methods for lead-zinc ore beneficiation. This article explains how to use gravity and froth flotation to effectively separate minerals.

View detailsTransforming raw quartz into high-purity silica sand is a very smart business move in 2026. Many investors focus only on crushing rocks into smaller pieces, but true profit comes from high purity and perfect grain shape. A specialized quartz sand...

View detailsAlluvial gold washing often fails when sticky clay exists in the ore. This clay creates mud balls that trap gold particles and carry them into the waste piles. Breaking these mud balls requires high-energy mechanical force and specific equipment....

View detailsGravity separation remains the primary method for gold recovery in both artisanal and industrial mining operations. It functions on the principle of Specific Gravity (SG), utilizing the density difference between gold (SG approx. 19.3) and typica...

View details