9 Ways to Boost Iron Ore Beneficiation Efficiency

3864Boost iron ore plant performance. Learn strategies to boost recovery, enhance concentrate grade, and optimize operational efficiency for higher profits.

View detailsSearch the whole station Crushing Equipment

Let’s be blunt: “Oxidized gold ore” is one of the most dangerously simplistic terms in mining. A rookie hears “oxidized” and thinks “easy gold, cheap to process.” A veteran hears “oxidized” and asks, “How much clay? And more importantly, what kind of clay?”

The answer to that second question dictates everything. Your entire oxidized gold ore processing flowsheet, your capital cost, and whether you make money hinges on it. This guide will walk you through the process, focusing on selecting the right gold processing equipment by first understanding your ore.

An oxidized gold ore is a type of ore where the original sulfide minerals have been broken down by weathering (exposure to air and water). This is good news and bad news.

The hard part isn’t dissolving the gold; it’s physically moving sticky, variable material through a plant without it grinding to a halt. Your equipment choice is a strategy to defeat the mud.

Before you buy a single piece of gold processing equipment, you need a detailed metallurgical report. This is non-negotiable. It must tell you:

These three factors will point you down one of two strategic paths.

Your entire plant design will follow one of two strategies, dictated by your ore.

The goal of crushing depends entirely on which path you take.

Your goal is to create a crushed product with minimal fines. The key equipment includes:

Your goal is simply size reduction for the mill. Fines are not a concern.

This is a trick question. The “grinding” stage is fundamentally different for each path.

You do not grind the ore. Instead, you agglomerate it to improve permeability. Key equipment includes:

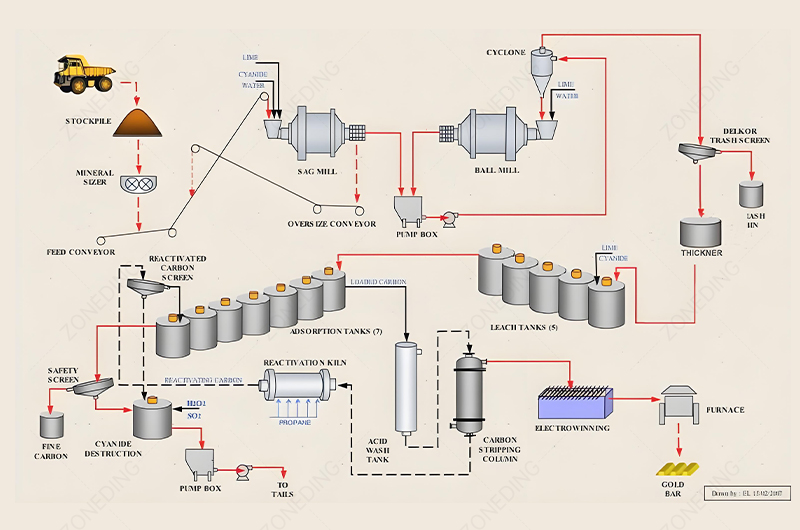

Here, grinding is essential for liberation.

This is the core of your Gold Processing Plant where the gold is dissolved.

The “equipment” is a large-scale civil engineering project.

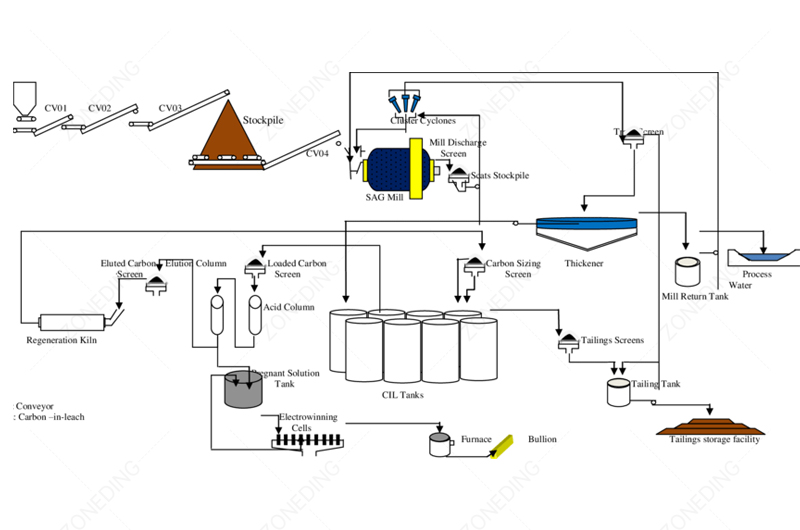

This is where the CIL process takes place in a series of controlled tanks.

Once the gold is loaded onto the activated carbon, the recovery process, often called the elution circuit, is similar for both paths.

The answer always starts with your ore report. That report will tell you which path to take.

| Feature | Path 1: Heap Leach Flowsheet | Path 2: CIL/CIP Flowsheet |

|---|---|---|

| Ore Type | Low-grade, good permeability, manageable clay | High-grade, high/swelling clay, fine gold |

| Crushing | Jaw Crusher + Cone Crusher (focused on minimizing fines) | Jaw Crusher + Cone Crusher (standard operation) |

| “Grinding” | Agglomeration Drum & Stacking System | SAG Mill / Ball Mill & Cyclone Circuit |

| Pre-Leach | (None) | High-Capacity Thickener |

| Leaching | Heap Leach Pad & Drip/Pond System | Leaching Agitation Tanks with carbon circuit |

| Gold Recovery | Desorption & Electrowinning + Smelting | Desorption & Electrowinning + Smelting |

| Result | Lower capital cost, lower recovery (60-80%) | Higher capital cost, higher recovery (90-97%) |

Trying to force a high-clay ore down the heap leach path to save money is a recipe for disaster. You won’t build a mine; you’ll build a very large, very expensive mud pie.

1. What is the biggest challenge in oxidized gold ore processing?

The biggest challenge is not the gold chemistry; it’s managing the physical properties of the ore, specifically the content and type of clay. High clay content can cause major material handling problems, blind screens in CIL circuits, and completely block solution flow in heap leaching, making it the single most important factor in choosing the correct processing route and equipment.

2. Should I choose Heap Leaching or a CIL process for my oxidized gold ore?

The choice depends entirely on your ore’s characteristics found in a metallurgical test report. Heap Leaching is a low-cost option for low-grade ores with good permeability and low-to-moderate clay content. A Gold CIL Plant is a more expensive but robust solution for high-grade ores, ores with high or swelling clay content, or ores that require fine grinding to liberate the gold.

3. What is an agglomeration drum and why is it important for heap leaching?

An agglomeration drum is a rotating drum that mixes crushed ore with a binder (like cement or lime) and a small amount of cyanide solution. It rolls the fine particles onto larger ones, creating durable, porous pellets. This is critical for heap leaching because it prevents fine clay particles from turning to mud and blocking the flow of the cyanide solution through the heap, ensuring good permeability and gold recovery.

4. Can gravity separation be used for oxidized gold ores?

Yes, and it is often highly recommended. If the ore contains even a small amount of coarse, free gold, using gravity separation equipment like a Centrifugal Concentrator before the leaching circuit can recover a significant portion of the gold very early and at a very low cost. This reduces the load on the CIL or heap leach process and improves overall plant efficiency.

5. What are the main factors affecting the cost of an oxidized gold processing plant?

The main cost drivers are: 1) Throughput (tons per day), which dictates the size of all equipment. 2) Ore Characteristics, as high clay content requires larger, more expensive thickeners and higher reagent consumption. 3) The Chosen Process, with heap leaching having lower initial capital cost (Capex) and CIL plants having higher Capex but often better recovery rates.

At ZONEDING, we are more than just an equipment manufacturer; we are process solution experts. Since 2004, we have provided robust gold processing equipment for projects worldwide. More importantly, we help our clients choose the right equipment. Our services include complete metallurgical testing, process design, and engineering for your entire oxidized gold ore processing plant. We understand the challenges of clay and will help you choose the correct path for a profitable operation.

Contact our engineers today to discuss your ore report and begin designing a plant that is built for your specific needs.

Boost iron ore plant performance. Learn strategies to boost recovery, enhance concentrate grade, and optimize operational efficiency for higher profits.

View detailsReduce costly downtime and extend the service life of your ball mill liners. Discover 5 expert solutions to diagnose and fix the root causes of rapid wear.

View detailsThe grinding process determines the success of mineral separation. Proper selection of grinding equipment in mining ensures a high liberation degree for mineral particles. This technical guide analyzes ball mills, rod mills, and SAG technology fo...

View detailsDive into the world of efficient mineral processing with our gold shaking table guide. Understand its mechanism, operation, and achieving high recovery rates.

View details