Rock Crusher for Gold Mining: How to Choose Portable Hard Rock Solutions to Maximize Recovery?

3603The perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsSearch the whole station Crushing Equipment

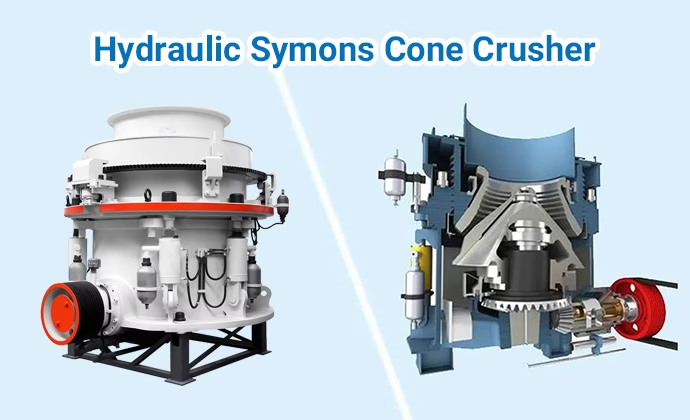

In mineral processing, the Cone Crusher is vital for medium and fine crushing. The Hydraulic Cone Crusher represents the most advanced form of this equipment. Its hydraulic technology transforms crushing operations. It significantly boosts efficiency, safety, and automation.

Many people understand Hydraulic Cone Crushers by their basic function of crushing ore. They know these machines offer high automation. However, the true value of a Hydraulic Cone Crusher lies deeper. Its hydraulic actions and smart adjustments boost production. They lower operating costs. They extend equipment lifespan.

This article will explain the Crusher Working Principle of a Hydraulic Cone Crusher. I will reveal key insights. These insights are crucial for your project. They help you understand its core value. You can maximize your investment return.

A Hydraulic Cone Crusher is an advanced type of Cone Crusher. It uses a hydraulic system for critical operations. This system manages adjustments, protections, and clearance. Traditional cone crushers, often spring-loaded, lack these hydraulic functions. This difference makes hydraulic versions more efficient, safer, and highly automated. They offer significant Hydraulic Crusher Advantages.

The core of its operation involves an eccentric sleeve. This sleeve drives a moving cone. The moving cone gyrates around a fixed main shaft. Material is crushed in the space between the moving cone and the stationary concave. This crushing occurs through compression, shear, and bending forces. The hydraulic system precisely controls these crushing parameters. This allows for superior performance and flexibility.

The introduction of hydraulics changed Crushing Equipment. It moved from simple mechanical setups to intelligent, controlled systems. Hydraulic systems provide precise, responsive power. This allows for dynamic adjustments. It offers robust overload protection. It also enables quick chamber clearing. These functions were impossible or cumbersome with traditional designs.

For example, adjusting the discharge opening on a traditional spring cone crusher required stopping the machine. It involved manual labor. With a Hydraulic Cone Crusher, this adjustment happens instantly. It is done with the push of a button. This capability alone dramatically increases operational flexibility. It enhances overall Crushing Efficiency.

The Hydraulic Cone Crusher works by compressing, shearing, and bending material. This happens between the moving cone and the stationary concave. The core of its efficiency lies in its hydraulic system. This system allows for precise control. It also enables the principle of layer crushing.

This crushing method creates superior aggregate products. The hydraulic system adjusts the crusher’s settings in real-time. This ensures optimal performance under varying conditions. It is a significant Hydraulic Crusher Advantage.

The Hydraulic Cone Crusher ensures its crushing chamber remains full or nearly full. It does this by precisely controlling the discharge opening. This creates a “layer crushing” effect (Inter-Particle Crushing). Here, most crushing force acts between material particles. This is instead of directly on liners and material.

Many operators avoid chamber fullness. They fear blockages. This leads to “thin layer” crushing. It prevents blockages. But it loses the benefits of layer crushing. This results in poor Product Particle Shape. More flaky or elongated particles are produced. Successful crushing is about “grinding” and “layer crushing”, not just “smashing.” The hydraulic system precisely controls this. It makes material particles break each other. This forms high-quality, cubical aggregate. This is crucial for construction projects.

The hydraulic system is the “brain” of the Hydraulic Cone Crusher. It gives the machine unmatched control. It enables real-time adjustments. These adjustments enhance efficiency and safety.

These capabilities reduce downtime. Increased productivity is a key advantage of hydraulic crushers. This benefit, central to their appeal, significantly differentiates them from older, less flexible crushing technologies.

Hydraulic Cone Crushers possess several advanced technical features. These features leverage hydraulic power. They make the crushers highly efficient, safe, and easy to operate. These innovations provide significant Hydraulic Crusher Advantages. They set modern machines apart from traditional models.

These features enable precise control. They also offer robust protection. They simplify maintenance. This results in superior performance for various applications.

The hydraulic discharge opening (CSS) adjustment is a key feature. It allows operators to change output particle size without stopping the machine. The real value is dynamic CSS adjustment. This can be done based on feed changes, screen load, or final product needs. It optimizes cavity fullness. It maximizes Crushing Efficiency.

Many operators set CSS once. They do not adjust it. This makes the crusher inefficient. It causes overload or under-crushing. The CSS is the “steering wheel” of the Hydraulic Cone Crusher. It controls product size. It also sets the pace of the entire Crushing Production Line. Modern hydraulic systems use PLC automation. They integrate sensors. This allows for closed-loop automatic adjustment. It ensures optimal operation.

Hydraulic overload protection offers instant, automatic unloading and resetting. It minimizes downtime. This occurs from non-crushable materials like tramp iron or sudden blockages. It protects the equipment from damage.

Traditional spring crushers require manual clearing. This causes long downtime. It risks damage to the frame. Poor hydraulic maintenance (e.g., low accumulator pressure) can make the system slow. It can also cause frequent false triggers. This protection system is the “immune system” of the Hydraulic Cone Crusher. It quickly clears threats. It restores normal operation automatically. This improves Mean Time Between Failures (MTBF).

| Feature | Traditional Cone Crusher | Hydraulic Cone Crusher | Your Benefit |

|---|---|---|---|

| CSS Adjustment | Manual, requires stopping | Automatic, on-the-fly | Increased uptime, precise product control |

| Overload Prot. | Spring release, manual clear | Hydraulic release, auto reset | Reduced downtime, enhanced safety |

| Chamber Clearing | Manual, dangerous | Hydraulic, one-button clear | Faster recovery, improved safety |

The hydraulic chamber clearing function is not just convenient. It ensures operator safety. It improves production efficiency. When blockages occur due to sticky material, power failure, or malfunction, the hydraulic system automatically lowers the moving cone. This quickly empties the crushing chamber.

Non-hydraulic crushers require dangerous manual clearing. This is time-consuming. It risks accidents. This hydraulic feature changes “passive waiting” to “active intervention.” It turns unexpected stops into manageable, brief interruptions. This significantly reduces downtime from blockages. It avoids manual clearing risks and labor costs.

The Hydraulic Cone Crusher through precise control of its discharge opening. It ensures the crushing chamber remains full or nearly full. This achieves “Inter-Particle Crushing.” This means most crushing force acts between material particles. It is not directly on the liners and material.

Many operators, to avoid blockages, use “thin layer” crushing. This prevents blockages. But it loses the advantage of layer crushing. This results in poor Product Particle Shape. More flaky or elongated particles are produced. Successful crushing is not just “smashing.” It is “grinding” and “layer crushing.” The Hydraulic Cone Crusher with precise control. It allows material to “crush” itself. This forms high-quality, cubical aggregate.

This is critical for projects needing excellent aggregate. These include high-grade concrete and highway pavement materials. The Hydraulic Cone Crusher is an irreplaceable choice. Good particle shape sells at a higher price. It reduces cement usage. It improves concrete strength. This brings significant economic benefits.

Modern Hydraulic Cone Crushers include automatic liner wear compensation. As liners wear, the hydraulic system automatically adjusts the moving cone’s position. This compensates for wear. It ensures the discharge opening setting remains constant. It maximizes Wear Parts Life.

Traditional crushers suffer from changing discharge size as liners wear. This requires frequent manual adjustments. It can lead to premature discarding of usable liners. Liner wear is no longer just consumption. It is a managed and optimized process. The hydraulic system turns liners from “wear parts” into “smart consumables.” This significantly increases liner utilization (15-30% longer lifespan). It reduces replacement frequency. It lowers downtime and maintenance costs.

Adjusting the main shaft’s rotation speed (often via a variable frequency drive) fine-tunes crushing characteristics. This impacts Product Particle Shape and processing capacity. While not as obvious as CSS adjustment, it is a powerful tool.

Most operators treat crusher speed as fixed. They miss its potential as a regulatory tool. Main shaft speed is the “heartbeat frequency” of the crusher. Changing it alters material stress time and frequency. This affects crushing results. Adjusting speed is effective when precise control over specific particle sizes is needed. It also helps when improving the shape of certain ores. Higher speeds often increase fine material output. They improve particle shape. Lower speeds help process coarser feed. They reduce fines. However, adjustment needs care. Too high or too low can reduce efficiency or cause abnormal wear.

Modern Hydraulic Cone Crushers often integrate lubrication and hydraulic oil stations. They share cooling and some filtering systems. This demands extremely clean oil. The lubrication system provides clean oil for both bearings and the hydraulic system.

Many customers neglect oil management. They assume regular oil changes are enough. However, oil contamination is a major cause of early failure. This affects hydraulic components (pumps, valves, cylinders) and main shaft bearings. Lubricating and hydraulic oil are the “blood” of the crusher. Their purity determines the equipment’s “health” and “lifespan.” Strictly following manufacturer guidelines for oil selection is critical. Regular oil analysis (checking moisture, particle size, wear metals) and efficient cooling system operation are fundamental. They ensure long-term stable operation. They prevent sudden failures.

High-end Hydraulic Cone Crushers have advanced sensors and PLC control systems. These systems offer real-time monitoring of crushing pressure, oil temperature, oil pressure, current, and vibration. They also provide detailed fault diagnosis information and even support remote monitoring and diagnosis.

Many factories only use basic start/stop functions. They do not fully use the powerful data collection and diagnostic capabilities. This leads to reactive maintenance after a fault occurs. The Hydraulic Cone Crusher is more than a mechanical device. It is intelligent equipment with a “brain” and “nervous system.” Predictive maintenance identifies potential problems early. It allows for planned shutdowns. This avoids significant losses from unplanned downtime. Remote diagnosis reduces service engineer travel costs and response time.

Hydraulic Cone Crushers offer various crushing chamber types. These include coarse, medium, fine, and extra-fine chambers. These types are not just different sizes. Their liner tapers and curve shapes are precisely designed. They adapt to different feed sizes and product requirements.

Customers often choose chamber types based on simple “coarse, medium, fine” categories. They overlook actual ore crushing characteristics. These include friability, abrasiveness, and clay content. They also miss specific final product shape requirements. The crushing chamber type is like a “tailored suit” for the crusher. Only the best fit yields optimal results.

Correct chamber selection optimizes Crushing Efficiency.It reduces energy consumption, extends liner life, and ensures final product quality meets market demand.

The hydraulic system provides the Hydraulic Cone Crusher with distinct advantages. It dramatically boosts efficiency, safety, and operational convenience. These enhancements stem from precise control and robust protection mechanisms inherent in hydraulic technology. This makes it a powerful crushing tool.

This integration transforms the crusher from a simple mechanical device into an intelligent, responsive machine. It ensures consistent output, minimizes risks, and simplifies daily operations. These are clear Hydraulic Crusher Advantages.

The hydraulic system allows for dynamic, on-the-fly adjustments to the discharge opening. This maintains optimal cavity fullness. It ensures continuous Crushing Efficiency. It also enables the superior “layer crushing” principle. This creates high-quality, cubical aggregate. This capability reduces over-crushing and minimizes energy waste. The ability to quickly clear blockages also reduces unplanned downtime, significantly improving overall productivity.

Overload Protection is a key safety feature. The hydraulic system automatically releases pressure when non-crushable material enters. This prevents damage to the crusher. It also eliminates the need for dangerous manual intervention. The hydraulic chamber clearing function allows operators to safely empty a blocked chamber with a push of a button. This protects personnel from hazards associated with manual clearing. These features reduce accident risks in the Crushing Production Line.

The hydraulic system simplifies various operational tasks. Discharge opening adjustment is automated. This reduces manual labor and speeds up changes. Fault diagnosis and remote monitoring capabilities allow for proactive maintenance. This reduces the need for on-site troubleshooting. The integrated lubrication and hydraulic systems simplify maintenance routines. This ensures cleaner operation and longer component life. These conveniences make the Hydraulic Cone Crusher highly user-friendly.

Hydraulic Cone Crushers significantly boost production value across various industries. This includes Mining Equipment, Aggregate Production, and construction. Their advanced features lead to higher efficiency. They produce better quality products. They also reduce operational costs. This maximizes profitability for businesses.

Their adaptability and robust performance make them indispensable. They meet the stringent demands of modern industrial processes.

For Aggregate Production, the ability to produce superior Product Particle Shape is crucial. The layer crushing principle of Hydraulic Cone Crushers yields cubical aggregate. This aggregate fetches higher market prices. It also performs better in concrete mixes. Precise control over product size minimizes waste. It meets specific market demands. This direct impact on product quality leads to higher revenue.

In mining, reducing downtime and extending Wear Parts Life directly impacts operational costs. Hydraulic overload protection and chamber clearing drastically cut down unplanned stops. Automatic liner wear compensation extends the life of costly wear parts. This reduces replacement frequency. It lowers maintenance expenses. These savings improve the overall economic efficiency of the Mining Equipment in the Crushing Production Line.

Construction projects often require large volumes of specific aggregate types. The high Crushing Efficiency and consistent output of a Hydraulic Cone Crusher ensure a steady supply. This meets project timelines. The ability to quickly adjust output size means greater flexibility. It helps adapt to varying project specifications. This reliability and efficiency translate into smoother project execution. It leads to better construction quality.

Selecting and maintaining a Hydraulic Cone Crusher correctly is vital. It ensures long-term stable operation. It maximizes your investment. Proper selection involves understanding your specific needs. Effective maintenance relies on diligent care. Both steps are crucial for achieving optimal Crushing Efficiency and minimizing downtime.

This guidance helps you make informed decisions. It also supports maintaining your Hydraulic Cone Crusher for peak performance.

When selecting a Hydraulic Cone Crusher, consider these key factors:

Effective maintenance of your Hydraulic Cone Crusher ensures its reliability and extends its service life:

Following these selection and maintenance guidelines will help you achieve maximum output. It ensures the longevity of your Hydraulic Cone Crusher.

Question 1: What is a Hydraulic Cone Crusher and how is it different from traditional cone crushers?

A Hydraulic Cone Crusher is an advanced Cone Crusher. It uses a hydraulic system for various functions. This includes adjusting discharge opening, overload protection, and chamber clearing. Traditional cone crushers, like spring types, lack these hydraulic features. This makes hydraulic crushers more efficient and automated.

Question 2: How does the hydraulic system enhance Crushing Efficiency?

The hydraulic system allows for dynamic adjustment of the discharge opening. This maintains optimal crushing cavity fullness. It ensures continuous Crushing Efficiency. It also provides automatic overload protection. This reduces downtime. These are key Hydraulic Crusher Advantages.

Question 3: What are the benefits of layer crushing in a Hydraulic Cone Crusher?

Layer crushing means material breaks against other material, not just against the liners. This leads to a superior Product Particle Shape. It produces more cubical aggregate. This is highly valued in the construction industry. It reduces Wear Parts Life significantly as well.

Question 4: How does a Hydraulic Cone Crusher improve safety and convenience?

The hydraulic system provides automatic overload protection. It clears blockages safely and quickly. This eliminates dangerous manual intervention. It minimizes downtime. This makes the operation safer and more convenient for operators. It is a major Hydraulic Crusher Advantage.

Question 5: What should I consider for Crushing Equipment Selection for a Crushing Production Line?

For Crushing Equipment Selection, consider your material’s properties and desired product size. Evaluate the specific technical features of different crushers. Hydraulic Cone Crushers offer flexibility in output size. They also provide robust protection and high automation. These are crucial for optimizing a Crushing Production Line .

The Hydraulic Cone Crusher is a vital part of modern mineral processing plants. Understanding its Crusher Working Principle and key features is crucial. Using its hydraulic system wisely helps manage the entire crushing process. This optimizes production efficiency. It lowers operating costs. It increases product value. My experience shows that deep understanding and practice of these details help you succeed in a competitive market.

To maximize your investment, prioritize dynamic adjustment of the discharge opening. Leverage automatic overload protection. Implement proactive maintenance. Choose the right crushing chamber type for your specific ore. Embrace data-driven monitoring for continuous optimization. These steps ensure peak performance and profitability for your Crushing Equipment.

ZONEDING has been a leader in mineral processing since 2004. We provide a full range of Crushing Equipment and Beneficiation Equipment and solutions. We serve clients worldwide. ZONEDING specializes in customized crushing solutions. Our machines are recognized for reliability, efficiency, and top performance. We offer full-process support. This covers design, manufacturing, installation, and after-sales service. ZONEDING assists in achieving superior production value. This ensures a successful investment.

Contact us today. Our experts can assist in designing or optimizing any Crushing Production Line. Maximize your mineral value with ZONEDING’s proven technology and experience.

The perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsBuild an efficient quartz sand plant. See our advanced equipment for high-quality production & get a precise quotation tailored to your operational needs.

View detailsDesigning a Copper Ore Beneficiation Process Design requires a rigorous analysis of micro-mineralogical characteristics rather than relying on generalized rules. The traditional approach of simply floating sulfides and leaching oxides o...

View detailsHigh Pressure Grinding Rolls (HPGR) and Vertical Roller Mills (VRM) continue to gain attention in the market. However, the Ball Mill still holds over 80% of the global market share in mining. This dominance is not merely due to tradition. It stem...

View details