Search the whole station Crushing Equipment

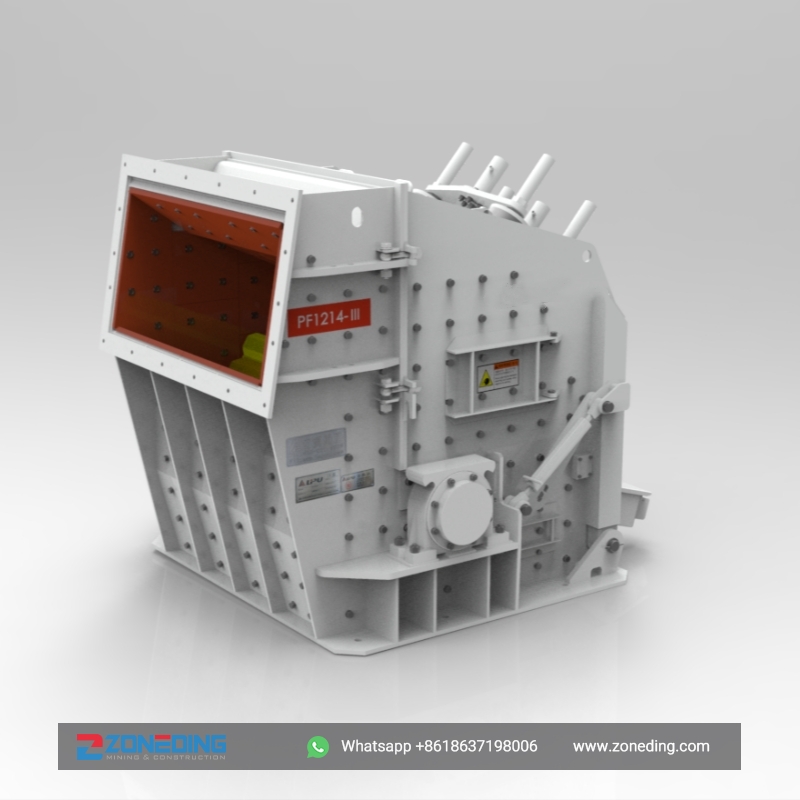

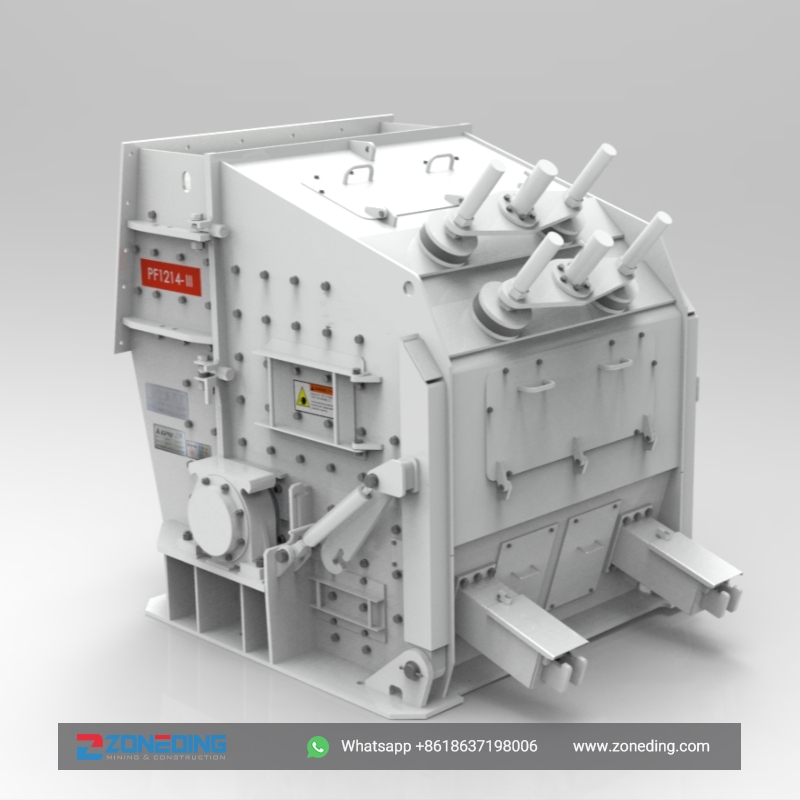

Impact crusher excel in primary crushing of rock. Stationary and mobile plants are available. Replacement of wearing parts is simple due to the hydraulic folding of the housing components.

A variety of models are available | Get the free price list!

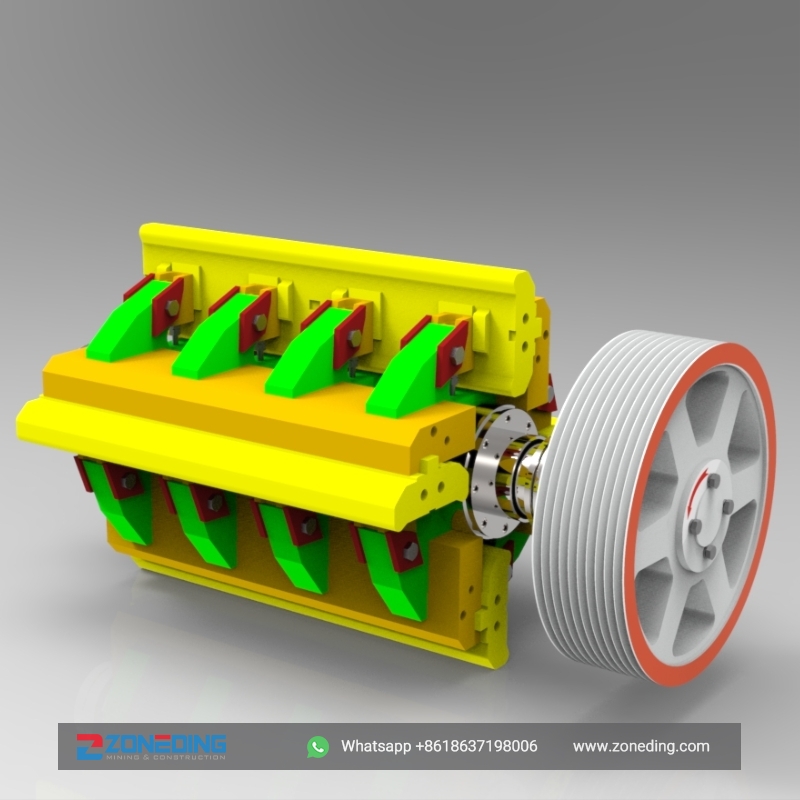

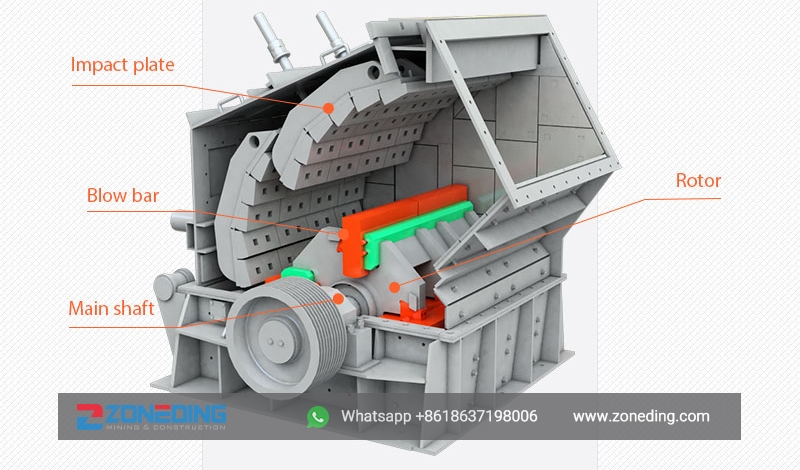

Impact crusher is a kind of crusher which utilizes impact energy to crush materials. It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with feed size not more than 500mm and compressive strength not more than 350MPa, and is widely used in all kinds of ore crushing, railroad, highway, energy, cement, chemical, construction and other industries. It adopts updated manufacturing technology and unique structural design. The finished product is cubic with no tension or cracks. Our impact breaker series is divided into two series: two-chamber and three-chamber series.

Impact crushers are versatile machines that have a wide range of applications across various industries. Here are some of the main applications of impact crushers:

The versatility and high efficiency of impact crushers make them a valuable asset in many industries that require material reduction and recycling.

Here is a brief overview of the working principle of an impact crusher:

| Model | Specification(mm) | Feed Opening(mm) | The Maximum Feeding Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension(mm) | Total Weight(t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

PFW-1315, PF-1214, and PF-1210 impact crushers perform well in processing medium-hard materials, with high crushing efficiency and large crushing ratio. The product shape is mostly cubic, with the advantage of selective crushing, and the discharge particle size is adjustable, simplifying the process.

PF-1010 and PF-1007 may have slightly lower processing capacity, but users still favor their compact structure, flexible layout, and low investment cost in some occasions where the output requirements are not particularly high.

It contains feeding, coarse crushing, medium crushing, screening, optional fine crushing, conveying, and storage and transportation of finished products. Feeding through the vibrating feeder uniform continuous feeding, coarse crushing by the jaw crusher will be crushed into small pieces of stone, crushing in the impact crusher, and then by the vibrating screen screening, does not meet the requirements of the particle size of the stone returned to the re-crushing, for the higher requirements of the particle size of the optional fine crushing links, between the links by the belt conveyor transportation stone, finished products are stored in the yard and transported as needed.

Application Areas: Sand and gravel production lines, dehydration stage in ceramic raw material processing systems, tailings recovery and treatment in concentrators, quartz sand processing systems, sand and gravel processing systems for hy…

Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc. Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials…

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. Cone crusher is ideal for crushing different stone and rock…

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also. It has the characteristics of stable and reliable work, easy maintenance, and a high sand production rate. The…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy