10 Key Points to Improve Gold Recovery Rate

4019From fundamental theory to practical application, grasp the top 10 crucial elements for enhancing gold recover to boost your gold recovery rate.

View detailsSearch the whole station Crushing Equipment

You’re asking about the ball mill price. That tells me you’re focused on the wrong number. I’ve seen miners lose millions not because they bought an expensive mill, but because they bought the wrong mill. The ball mill is the heart of your gold recovery circuit. Get it wrong, and you are actively throwing away gold every hour.

Choosing the right Gold ore ball mill is a critical engineering decision, not a shopping trip. An incorrect ball mill model, liner, or steel ball charge leads to poor recovery, high energy consumption, and excessive wear, costing far more in lost profit than the initial equipment price.

The price of the machine is a one-time expense. The cost of a poorly chosen machine is a daily, unending loss. Let’s walk through the questions you should be asking to ensure you select a machine that makes you money, not one that drains it.

You want a model number, but you haven’t defined the workload. It’s like asking for a truck engine without knowing if you’re hauling feathers or lead.

The very first parameter for any equipment selection is your target throughput, measured in tons per day (TPD) or tons per hour (TPH). This fundamental number dictates the required volume, diameter, and length of the ball mill needed to achieve the target grind.

Throughput is the foundation of your entire plant design.

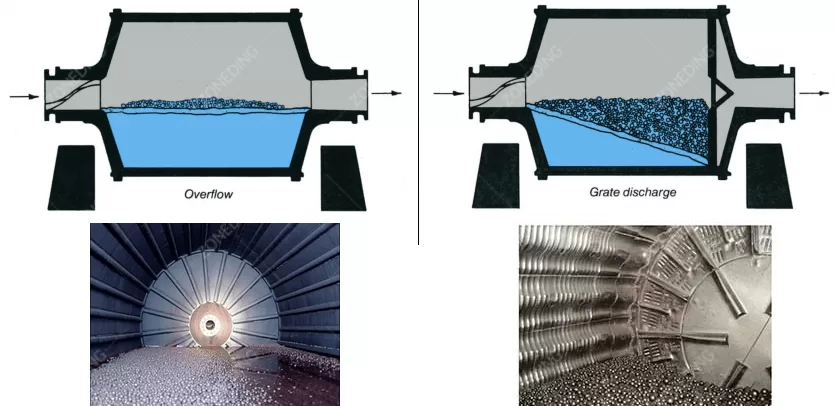

You’ll see two main types of wet ball mills offered. They look similar from the outside, but their internal discharge mechanism is critically different.

The choice depends on your desired product size and downstream process. An overflow type ball mill is simpler and used for finer grinds. A grate type ball mill discharges faster, is used for coarser grinds, and prevents over-grinding.

This choice directly impacts your grinding efficiency and the characteristics of your final product.

| Feature | Overflow Type Ball Mill | Grate Type Ball Mill |

|---|---|---|

| Discharge Mechanism | Slurry overflows from a discharge trunnion when the mill is about 70% full. | Slurry passes through grates at the end of the mill, which lift and discharge it. |

| Slurry Level | High | Low |

| Grinding Action | More attrition, longer retention time. | More impact, faster passage of material. |

| Typical Product Size | Finer grind (e.g., below 150 microns). | Coarser grind (e.g., above 200 microns). |

| Best For… | Most cyanide leaching (CIL/CIP) circuits that require very fine liberation of gold. | Primary grinding stages or circuits with a gravity concentrator where you want to avoid over-grinding coarse, free gold particles. |

Now we get to the science. Guessing your mill size and motor power is a recipe for disaster. The hardness of your ore is a measurable number, and it’s the key to proper sizing.

The Bond Work Index (BWi) quantifies your ore’s resistance to grinding. This value, combined with your throughput and target grinding fineness (P80), is used in engineering formulas to calculate the precise motor power (kW) required, which in turn determines the correct ball mill model.

Do not skip this step. A lab test is the cheapest insurance you will ever buy.

A single number on a piece of paper is not a quote; it’s a trap. A professional quote is a detailed technical proposal that shows you exactly what you are paying for.

A low ball mill price often hides missing components. A proper quote is a multi-page document detailing the mill shell, drive system (motor, gearbox, gears), liners, lubrication system, and other critical auxiliaries. The total installed cost is the only number that matters.

If a supplier only gives you a price for the steel cylinder, they are not a serious partner.

Ball mill liners are not just wear protection; they are functional parts that control the grinding action. The material you choose depends on the type of wear your mill will experience.

High-manganese steel is the standard choice for primary gold ore ball mills due to its toughness and ability to work-harden under impact. High-chrome cast iron is better for secondary or regrind mills where abrasive wear is dominant over impact.

Matching the material to the application is key to maximizing liner life and reducing your cost per ton of ore.

The ball charge is the engine of your mill. A poorly managed charge means you’re just wasting energy polishing rocks instead of breaking them.

The largest grinding steel ball size is determined by the largest feed ore size. A graded steel ball ratio is used for the initial charge, but makeup balls should only be of the largest size to maintain an equilibrium grind.

This is one of the most critical operational aspects to get right.

Your grinding circuit does not exist in isolation. It must be optimized for the recovery method that follows it.

Your downstream process dictates grinding requirements. Cyanide leaching often requires a very fine grind (e.g., P80 < 75 microns) to liberate gold, favoring an overflow mill. Flotation may have a coarser grind target and is very sensitive to the type of grinding media used.

The mill must prepare the ore perfectly for the next step.

Stop asking for the ball mill price and start a technical conversation. The right gold ore ball mill is a custom-engineered solution based on your ore, your tonnage, and your process. Investing in proper testing and engineering upfront will pay for itself a thousand times over in increased gold recovery and lower operating costs.

From fundamental theory to practical application, grasp the top 10 crucial elements for enhancing gold recover to boost your gold recovery rate.

View detailsThis complete guide compares crusher types, analyzes application needs, and helps you select the most efficient machine for your job.

View detailsIron ore beneficiation separates valuable metal from waste rock to increase grade and reduce smelting costs. This process determines the economic viability of mining projects. This article analyzes technical details ranging from crushing to dewat...

View detailsAchieve peak performance with optimal limestone sand production line ensure superior aggregate quality, max output, and lower operating costs via our solutions.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy