Search the whole station Crushing Equipment

You have magnetite ore. You want to make it high-grade iron concentrate. This is a goal for many companies. It is how you get more value from your mine. ZONEDING has worked with magnetite for a long time. ZONEDING builds the machines that do this job. ZONEDING has seen how to make lower grade rock into high-grade product. It takes the right steps and the right machines. This article will tell you how. It will share what ZONEDING learned from many projects.

Last Updated: March 2025 | Estimated Reading Time: 18 Minutes

Processing magnetite ore is different from processing other iron ores. Other common ores are hematite or limonite. Magnetite has very strong magnetic properties. This is the biggest difference. Hematite and limonite have only weak magnetic properties or no magnetism at all. This strong magnetic feature of magnetite is a great advantage. It means you can use magnetic fields to separate the iron minerals from the other rock. This method is called magnetic separation. It works very well for magnetite ore.

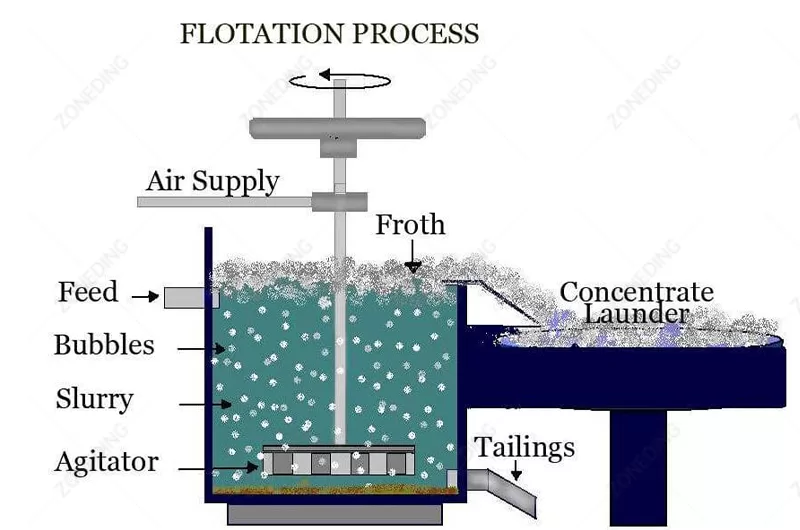

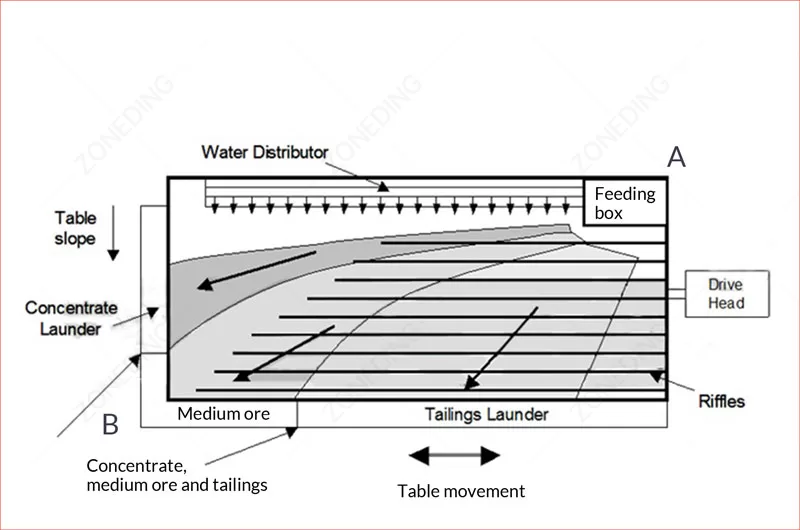

Hematite and limonite need different methods. They often use gravity separation. They also use flotation. These methods separate minerals based on how heavy they are. They also use chemicals that make minerals react with water and air differently. Magnetite can use these methods too. But magnetic separation is usually the first and most important step. It is often simpler and costs less for magnetite than for other ores. It uses the force of magnets. This force pulls the magnetic magnetite away from the non-magnetic rock pieces. This makes the process for magnetite often simpler in the first stages. You crush the ore. You grind it to free the minerals. Then you pass it through a magnetic field. This magnetic property is the key difference in processing magnetite.

Processing magnetite uses its magnetic power. You use magnets to pull the iron out. This is easy to do. It is different from floating minerals in water. It is different from using gravity to separate things by weight. This magnetic method is the best way to start with magnetite. It removes a lot of the waste rock early. This makes the next steps easier. ZONEDING builds strong magnetic separators for this reason. They are made to capture the magnetic particles efficiently.

Knowing these details guides the whole process design. For ore that has both hematite and magnetite, you might use magnets first for the magnetite. Then you might use flotation machines to remove the weakly magnetic hematite or the remaining non-magnetic waste. This is one way to get a higher iron content in the final product.

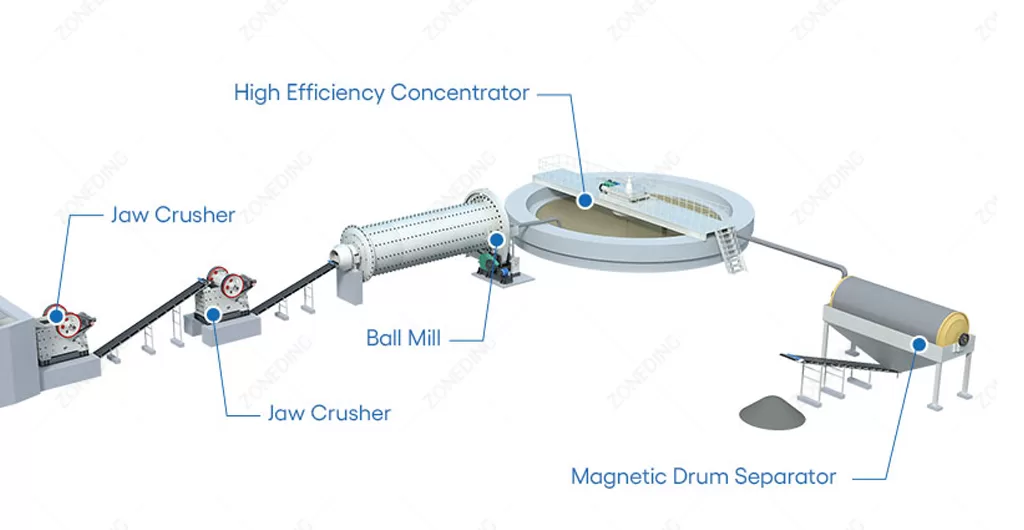

Crushing and grinding are very important steps for magnetite. You need to break the rock pieces. This frees the magnetite mineral from the other rock that is not iron. This is called liberation.

If you do not break the rock enough, the magnetite is still attached to larger pieces of waste rock. You cannot separate it well. If you break or grind it too much, you waste energy. You can also lose very fine iron particles later in the process. This makes the final iron product have a lower iron amount.

Using a closed circuit grinding system helps control the size. In a closed circuit, the material that is still too big after going through the grinding machine goes back to the machine again. This makes sure all the material gets ground to the right size. It also stops the machine from grinding material that is already small enough. Grinding uses a lot of electricity in a processing plant. Choosing the right grinding machines like efficient ball mills and making the grinding process work well saves a lot of money on power costs. It also helps you get better iron concentrate.

Grinding is the step that uses the most electricity in a magnetite processing plant. The machines like ball mills are very large and heavy. They need a lot of power to turn and crush the rock. There are many important factors.

An automated system can adjust the feed rate. This keeps the mill working at its best power usage. This saves energy and reduces operating costs. Choosing grinding mills that are designed to be efficient also helps.

Magnetic separation is the most important step for processing magnetite. It works because magnetite is very strongly magnetic. You use a magnetic field to pull the magnetic parts away from the parts that are not magnetic. This is the quickest and least expensive way to remove most of the unwanted rock from magnetite ore. It is a very effective way to increase the iron content early in the process.

You can perform magnetic separation in two main ways: using water (wet) or without water (dry).

You choose wet or dry based on the size of your material.

Most magnetite plants use wet magnetic separation after grinding. Some plants might use dry separation first on the crushed ore. Then they grind the material that was caught by the dry magnet and use wet separation. This is called pre-concentration. It makes the material smaller and lighter that needs to go to the expensive grinding step. This saves power and money.

The strength of the magnetic field in a magnetic separator is very important. This strength is measured in units like Gauss. Different separators have different strengths. The type of magnet used (like ceramic or rare earth magnets) affects the strength. The distance between the magnets and the material also matters.

An expert tip: The speed of the drum in a wet magnetic separator affects how well it works.

You need to adjust the drum speed and the water flow carefully for the best result with your specific ore. ZONEDING builds magnetic separators with adjustable settings. This allows you to fine-tune the process for your material.

Strong magnetic separation is the main step for processing magnetite. It removes most of the rock that is not magnetic. But sometimes, it might still have some waste minerals mixed in. Or the original ore might contain other iron minerals like hematite that are only weakly magnetic.

In these situations, you need other methods to clean the concentrate even more.

But for finely ground magnetite, flotation is more often used to get a very high grade concentrate. It is especially useful when you need to remove silica (which comes from quartz) or other waste minerals that are not magnetic and are still in the magnetic product. The goal is to reach a very high percentage of iron. This high percentage is often needed for making iron pellets or for direct reduction steelmaking.

Using magnetic separation first removes the bulk of the waste. Then flotation cleans the magnetic product further. This combined approach helps you get very high iron grades.

There is not one single process that works perfectly for every magnetite ore. Each ore deposit is different. The amount of iron changes. The size of the iron pieces within the rock changes. The types of waste rock mixed in also change. Because of this, the processing plant layout must be designed specifically for that particular ore. This is why custom design is very important.

Here are some common ideas for designing the process based on different magnetite ores:

There is no standard process design that fits every situation. A core truth: You must test your specific ore in a lab first. This testing shows how your ore behaves. It shows how fine you need to grind it. It shows how well magnetic separation or flotation works for your ore. Based on these tests, engineers can design the best process flowchart for your specific material. This customized design is essential for getting good results and not wasting money on unnecessary equipment or steps.

ZONEDING always advises detailed ore testing before designing a plant.

Before building a large, full-size processing plant, many companies build a small test plant. This is called a pilot plant. A significant advantage: A pilot plant lets you test the process design using a larger amount of your actual ore. They are helpful but cannot show everything that happens in a real plant. You can run the pilot plant for several days or weeks. You can see how the machines really perform with your ore. You can find problems in the design before building the big plant. You can see if the process achieves the iron grade and recovery amount you expect. This helps you make changes to the design before spending a lot of money on the large plant. It reduces the risk of building a plant that does not work well. This is a very important step, especially for complex ores or large mining projects.

Processing magnetite creates a large amount of waste rock. This waste is called tailings. It is the material left after you take out the valuable iron. Tailings are usually very fine particles mixed with water. You have a large volume of this material that you need to manage. You must handle it in a safe way. You also need to do it in a way that does not cost too much money. Protecting the environment is also very important.

Water is used in the wet magnetic separation and flotation steps. This water ends up mixed with the tailings. Getting this water back saves money for you. It also helps the environment by reducing the amount of water that needs to be stored with the tailings.

A technical point: How well the thickeners and filter presses work directly affects how much water you can recover. A good thickener makes the slurry very dense before it goes to the filter. This makes the filter press work better and faster. A filter press that works well removes most of the water. The water that comes out is much cleaner. It can be sent back to the beginning of the plant to be used again. This is called a closed-loop water system.

ZONEDING offers thickeners and filter presses that are designed to do this job efficiently.

Selecting the main machines is very important when you plan a plant for processing magnetite. The way these machines perform directly affects how much high-grade iron you can produce. It affects how much money it costs you to run the plant. It also affects how long the plant can operate without major problems. You need to choose machines that work well together. They must be suitable for your specific ore.

When you choose equipment, do not just look at the price tag. Think about how well the machine performs its job.

An engineering detail: You need to balance the capacity of the crushers, the mills, the separators, and the filters. The grinding mill must be able to process all the ore that the crusher produces. The magnetic separator must handle all the slurry from the mill. The filter press must dewater all the concentrate from the separator. This matching of equipment sizes is a key part of good plant design. It helps avoid problems where one machine limits the output of the entire plant. ZONEDING can provide suitable design for you.

Modern processing plants can use automation. Sensors can measure many things in the plant.

This information goes to a computer system. The computer system can make small changes to the machines in real-time, moment by moment. For example, it can change how fast the ore feeder sends material to the ball mill. It can change the amount of water going into the magnetic separator. This keeps the process running smoothly and at its best performance all the time.

A benefit of using data: You can track how any changes you make affect the quality of the final product and how much iron you recover. For example, if you change how long you grind the ore, the data will show you if the iron content in the concentrate gets better or worse. Smart control systems can also help predict when a machine might be about to break down. This allows you to fix it before it causes a stop. This saves a lot of money from unexpected shutdowns. It increases the total amount of time the plant is running. This directly increases the amount of iron you produce.

The final high-grade magnetite concentrate must meet very high standards. This is because it is the main material used to make iron pellets. It is also used to make direct reduced iron (DRI). These products are used in steel plants to make steel. Steel plants need very clean raw materials. They have strict rules about the quality of the iron concentrate.

A challenge to note: Different buyers might have slightly different quality requirements. You need to adjust your process slightly depending on your customer. Producing a consistent product with high quality, batch after batch, is a sign that your plant is well-managed and efficient.

New ideas and technologies are appearing. In 2025,some clear trends are seen.

The goal of these trends is to make processing magnetite more efficient. It is about getting more value from the ore. It is also about making the process more sustainable for the environment and less costly to run.

Question 1: What does it mean that magnetite is strongly magnetic?

It means magnetite is easily pulled by a magnetic field. This is different from most other minerals, which are not pulled or are pulled very weakly. This lets us use magnets to separate magnetite from rock.

Question 2: Why is the size of ore particles important for processing?

The size affects how well the minerals separate. You need to break the rock small enough to free the valuable mineral from the waste rock. This is called liberation. Different machines work best with different particle sizes.

Question 3: Can dry magnetic separation be used for very fine magnetite powder?

Generally, dry magnetic separation works best for larger particles. For very fine magnetite powder (like after grinding), wet magnetic separation is usually better. Water helps the fine particles move freely, which helps them separate well in the magnetic field.

Question 4: What is the biggest cost in running a magnetite processing plant?

The biggest cost is often electricity, mainly used by the grinding machines like ball mills. Water usage and chemical costs (if using flotation) are also significant.

Question 5: How often should I maintain the processing machines?

Machines need regular maintenance. You should check machines daily. Follow the schedule given by the machine maker for more detailed service. Keeping machines clean and maintained prevents big problems and keeps the plant running.

Question 6: Can I use tailings for anything useful?

Yes, people are looking into using tailings. They can potentially be used as material for building roads, cement, or bricks. Sometimes, valuable minerals that were not fully recovered can be taken from tailings.

Getting high-grade iron from magnetite ore needs a well-planned process.

First, you must deeply understand your specific ore’s properties. Crushing and grinding prepare the ore. Grinding must reach the right fineness to free the magnetite. Magnetic separation is the main method for magnetite. Wet magnetic separation is typically used for fine material. Sometimes, flotation is needed to further clean the concentrate and reach very high iron percentages.

Managing the large amount of waste rock (tailings) safely and efficiently is crucial for the environment and costs. Removing water from the final concentrate using thickeners and filter presses is important to meet quality needs. Picking the correct main machines that work well together is key for good plant performance. Using smart control systems and continuously improving the process helps get more iron recovery and lower operating costs. The final high-grade concentrate must meet strict quality rules, especially low levels of unwanted elements, for making pellets or steel.

ZONEDING builds machines for processing minerals. The company has helped many companies process magnetite ore. ZONEDING understands crushing, grinding with ball mills, magnetic separation, and dewatering with filter presses. ZONEDING’s machines are built strong and reliable. The company offers support for design, installation, and ongoing service.

If you have magnetite ore and want to produce high-grade iron, ZONEDING can help. ZONEDING can look at your ore and your needs. ZONEDING can suggest the right machines and the best process flow for you. Contact ZONEDING today to discuss your magnetite project.

Last Updated: March 2025

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy