Search the whole station Crushing Equipment

Setting up a Coal Processing Plant can be a complex but rewarding venture. This guide covers everything from understanding coal formation to choosing the right Coal Preparation Plant equipment. Whether you’re interested in Coal Washing for thermal coal or maximizing clean coal applications, ZONEDING can help you navigate each step of the process. This comprehensive guide can help you optimize your plant, reduce costs, and meet environmental standards.

Last Updated: November 2024 | Estimated Read Time: 15 minutes

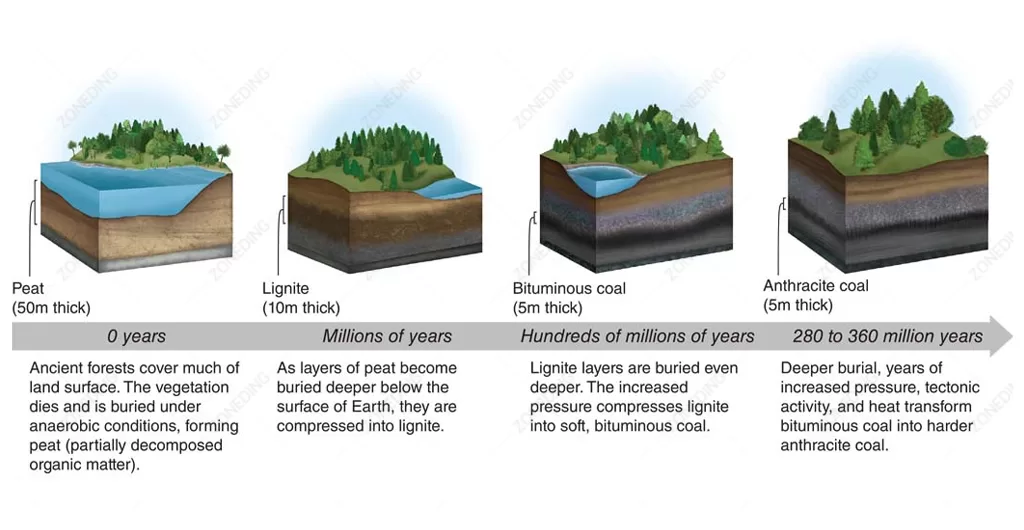

Coal is a sedimentary rock formed from accumulated plant matter over millions of years. The main types of coal include anthracite, bituminous, sub-bituminous, and lignite. Understanding these differences is vital for Coal Preparation.

Coal formation begins in swamps and peat bogs. Here, dead plant matter builds up. Over time, layers of sediment cover this material. The weight of these layers creates pressure. Heat from the Earth’s core also acts on the material. This process takes millions of years. It changes the plant matter into coal. The type of coal depends on how much pressure and heat were applied. Anthracite is the highest grade of coal. It has the most carbon and gives off the most heat. Lignite is the lowest grade. It has more moisture and less carbon. You can find coal deposits all over the world. Big reserves are in countries like the United States, Russia, China, and Australia. ZONEDING’s equipment is built to handle all types of coal. This ensures good Coal Beneficiation no matter where your coal comes from.ZONEDING’s can efficiently reduce moisture content. This makes your coal better for many uses.

| Coal Type | Carbon Content | Moisture Content | Energy Density | Application |

|---|---|---|---|---|

| Anthracite | High | Low | High | Industrial, Heating |

| Bituminous | Medium | Medium | Good | Power Generation, Coking |

| Sub-bituminous | Lower | Higher | Lower | Power Generation |

| Lignite | Lowest | Highest | Lowest | Power Generation |

Coal Preparation, also called Coal Washing or Coal Beneficiation, removes unwanted materials from coal. This makes the coal better quality and more valuable. It uses different ways to separate good coal from impurities.

Coal Preparation is like cleaning a dirty fruit. You want to eat the good part and throw away the bad. This process takes raw coal and makes it ready for use. It usually involves breaking the coal into smaller pieces. Then, you sort it by size. After that, you separate the good coal from the dirt or rock. This can be done by looking at how heavy things are, or how their surfaces act. The goal is to get rid of ash, sulfur, and other things you do not want. The result is clean coal that has more energy. Good Coal Preparation can make power plants work much better. It also cuts down on pollution. This improves the money side of Coal Mining. ZONEDING’s Crushing Equipment is made for different kinds of coal. It ensures the best Coal Beneficiation for your needs.ZONEDING provides complete Coal Processing Plant solutions. They are made for your specific coal type and processing needs.

Coal Preparation matters because it makes coal better. It boosts its heating value. It also lowers pollution and transportation costs. Good Coal Washing makes coal a more efficient and cleaner energy source.

Think about making a cup of coffee. You want pure coffee grounds, not dirt mixed in. Coal Preparation works like that. It cleans the coal so you get more energy from it. When you remove impurities, the coal burns better. This means you get more heat or electricity. It also means less ash and harmful gases like sulfur go into the air. This helps keep the environment cleaner. Another benefit is weight. When you take out the impurities, the coal weighs less. This saves money on shipping. So, Coal Preparation helps both the environment and your wallet. It makes using coal smarter and more responsible. ZONEDING’s Beneficiation Equipment makes sure your coal is cleaned to high standards. This helps you get the most value and reduce environmental harm.ZONEDING’s complete Coal Preparation solutions help you get these benefits. They also help you get the most out of your coal.

| Benefit | Impact | Result |

|---|---|---|

| Heating Value | Removes non-combustible materials | Higher energy output |

| Emissions Reduction | Removes sulfur and ash | Cleaner air, reduced environmental impact |

| Transportation Costs | Reduces weight and volume | Lower shipping expenses |

| Efficiency | Improves combustion process | More energy from less coal |

Clean Coal has many uses. These include making electricity, making steel, and heating factories. Using Clean Coal technologies helps reduce harm to the environment. It still lets us use coal for energy.

Clean Coal is like an upgraded version of regular coal. It goes through special cleaning to remove bad stuff. This cleaning happens before, during, and after you burn it. This makes it usable in many ways. It also leaves less of a mark on the environment. In power plants, Clean Coal methods, like carbon capture and storage (CCS), can greatly cut down on greenhouse gases. For making steel, Clean Coal provides the high-quality coke that is needed. It is also a steady and dependable heat source for different factory jobs. ZONEDING helps with the use of Clean Coal. We provide equipment that makes Coal Beneficiation effective and good for the environment.ZONEDING’s advanced equipment and processes support the making and use of Clean Coal. This helps you meet environmental rules and use resources fully.

Before cleaning coal, you should know how much cleaning is needed. You should also understand your coal’s traits. Learn how to get good coal samples. Know its washability. These points help you choose the best Coal Washing plan.

Think of cleaning coal like making a cake. You need to know your ingredients and recipe before you start baking. First, you must decide how clean you want the coal. This affects the methods you use. Then, you need to know your coal’s specific traits. This includes how much ash and sulfur it has. This information helps you pick the right cleaning technology. Taking a good coal sample is also important. If your sample is bad, your tests will be wrong. Washability tells you how easy it is to remove impurities. Some coal cleans easily, some is harder. Knowing all this helps you design your Coal Preparation Plant for the best results and lowest costs. ZONEDING gives expert advice and offers equipment. This helps you make smart choices about Coal Cleaning.

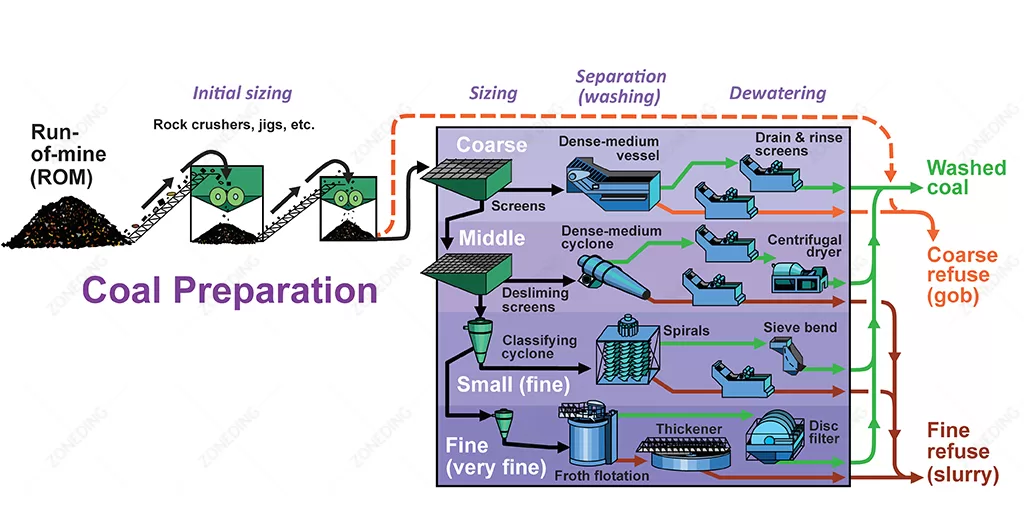

Coal beneficiation (also known as coal preparation or washing) enhances coal quality by removing impurities. This increases heating value, lowers ash, and reduces sulfur emissions. Coal Beneficiation uses several steps to remove impurities and improve coal quality. Key equipment includes crushers, screens, Jigging Separator Machine, Flotation Machine, and dewatering systems. Each step is important for making clean coal.

The process isn’t just a series of steps; it’s a carefully orchestrated flow using specialized equipment:

Throughout the plant, Conveyors transport material between each process stage, while Pumps move slurries. Sophisticated Instrumentation and Control Systems are essential for monitoring and controlling the entire beneficiation process. These integrated systems provide operators with the ability to adjust parameters to maintain optimal performance.ZONEDING has a full range of equipment for every step of Coal Beneficiation. This ensures your process works well and is effective.

Choosing the right Coal Cleaning technology depends on your coal’s type, particle size, and desired purity. Dense Medium Separation works well for large particles. Flotation is for small particles. Jigging can handle many sizes.ZONEDING gives expert advice. This helps you pick the right Coal Cleaning technology. It will fit your specific coal and processing goals.

Picking the right Coal Cleaning technology is like choosing the best tool for a specific job. If you have big pieces of coal, Dense Medium Separation (DMS) might be best. It uses a liquid that has a special density. The coal floats on top, and the heavier impurities sink. This is very good for getting high-quality coal. For very fine coal particles, Flotation Machine is often the choice. It uses chemicals to make the coal stick to air bubbles. The bubbles float the coal to the top, separating it from the dirt. Jigging Separator Machine uses pulsing water. This makes the particles separate by how heavy they are. It works for a range of sizes. Your choice should come from a deep look at your coal and what you want to achieve. ZONEDING offers all three methods. This means you can find the perfect solution for your Coal Preparation needs.

| Technology | Particle Size | Efficiency | Cost | Application |

|---|---|---|---|---|

| Dense Medium Separation | Coarse | High | Moderate | High-quality coal, coking coal |

| Flotation | Fine | High | Moderate | Processing coal fines |

| Jigging | Wide Range | Moderate | Low | General Coal Cleaning |

The choice between Wet Coal and Dry Coal depends on what you need and the environment. Wet Coal is easier to process but needs drying. Dry Coal uses less energy but can be dusty and hard to handle.

Wet Coal and Dry Coal are different ways to prepare coal. Each has good points and bad points. Wet Coal comes from processes that use water to clean. These methods are good at removing impurities. But, the coal stays wet. This makes it easier to move and work with at first. However, you must dry it later. This costs extra money and energy. Dry Coal has very little water. This makes it burn better and saves money on shipping because it is lighter. But, it can create a lot of dust. This means you need ways to control the dust. The best choice depends on your specific uses. It also depends on what environmental rules you must follow. ZONEDING has equipment for both Wet Coal and Dry Coal processing. We help you make the best choice for your work.ZONEDING provides solutions for both Wet Coal and Dry Coal processing. This includes dewatering systems and dust control equipment. We ensure your plant works its best.

| Feature | Wet Coal | Dry Coal |

|---|---|---|

| Moisture Content | High | Low |

| Processing | Easier | More Difficult |

| Energy Efficiency | Lower | Higher |

| Handling | Easier | Dustier |

To get the most from coal, you can use it for power, chemicals, and other things. Taking out impurities through Coal Preparation is very important. This makes every use better. It also lowers harm to the environment.

Coal is more than just something to burn. It is a useful resource for many industries. You can use it to make electricity in power plants. You can also change it into chemicals like methanol and ammonia. These chemicals are basic parts for many different products. Coal can also become liquid fuels or other valuable items. For any of these uses, cleaning the coal is key. When you remove the impurities, the process works better. It is like cleaning a machine. A clean machine runs more smoothly. This also means less pollution is released. This increases the money you can get from the coal. ZONEDING offers full plans for Coal Beneficiation and processing. We help you get all the benefits from this valuable resource.ZONEDING provides equipment and knowledge. We help you get the most value from coal for different uses. We ensure good impurity removal and top performance.

Meeting environmental standards with Green Coal means using technology to cut pollution. This includes Coal Preparation, capturing carbon, and better ways to burn coal.

Green Coal is the eco-friendly way to use coal. It involves methods that lessen its impact on nature. It starts with cleaning the coal well before it is burned. This removes many bad things. Then, technologies like carbon capture and storage (CCS) can catch carbon dioxide. This gas then goes underground. This stops it from harming the air. New burning methods, like super-efficient boilers, can also make more energy from less coal. This also means less pollution. By doing these things, coal can be used in a way that is better for the Earth. ZONEDING helps make Green Coal. We provide equipment that makes Coal Beneficiation efficient. This reduces the environmental footprint of using coal.

Storing and moving coal correctly stops dust, fires, and quality loss. Good ways include covered storage, enclosed conveyors, and dust control.

Storing and moving coal in the right way is very important. This keeps its quality. It also stops dangers like dust in the air or fires starting on their own. You can use closed storage places, like big bins or covered piles. This stops dust from escaping. It also lowers the chance of fire. Conveyor belts that move coal should be covered. Trucks that carry coal should also be covered. This helps stop dust when the coal is moving. Also, you can spray water or special chemicals on the coal. This helps control dust. By doing these things, your coal stays safe and good. ZONEDING provides equipment and plans for handling coal. This helps keep your coal in good condition during transport and storage.ZONEDING offers full solutions for coal storage and transport. We help you cut dust, stop fires, and keep your coal quality high.

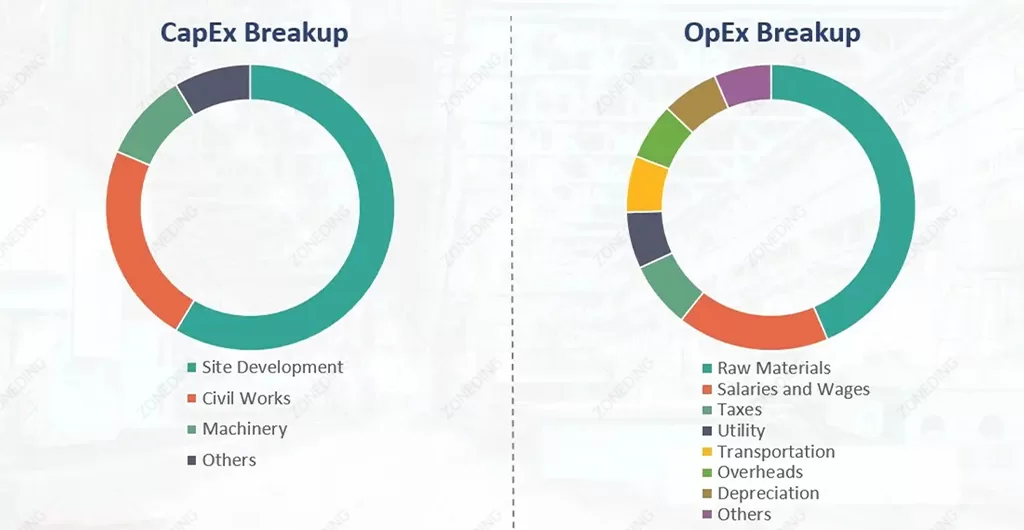

The cost for a Coal Prep Plant changes a lot. It depends on its size, where it is, and the technology used. Small plants might cost $5-15 million. Medium plants are $15-30 million. Large plants can cost $30 million or more.

A small plant, which can process a few hundred tons of coal every hour, might cost between $5 million and $15 million. A medium-sized plant, handling several hundred to one thousand tons per hour, could be $15 million to $30 million. A very large plant, processing thousands of tons per hour, can easily be $30 million or more. These costs cover many things. They include the machines, building the plant, getting permits, and the first costs of running it. Planning carefully and picking the right equipment can help you get the most out of your money. It also helps you earn money back faster. ZONEDING offers good value solutions. We also provide expert advice. This helps you plan your Coal Prep Plant investment well.

| Plant Size | Investment Range | Key Equipment |

|---|---|---|

| Small | $5 – $15 million | Crushers, Screens, Jigs |

| Medium | $15 – $30 million | Crushers, Screens, Jigs, Flotation |

| Large | $30+ million | Advanced Automation, DMS, Flotation |

Clean Coal Tech is the future of using coal. It focuses on cutting pollution and harm to the environment. This includes capturing carbon, better burning methods, and ways to turn coal into gas.

As the world seeks cleaner energy, Clean Coal Tech shows a way to use coal in a better, more lasting way. These technologies work to reduce bad gases like sulfur dioxide, nitrogen oxides, and dust. Carbon capture and storage (CCS) can catch carbon dioxide. This harmful gas can then be put underground. This lowers the amount of greenhouse gas in the air. Newer ways of burning coal, like super-efficient boilers, can make more energy. This means less coal is used for the same amount of power. It also means less pollution. Turning coal into gas, then burning the gas, is another cleaner way to make power. This method is called Integrated Gasification Combined Cycle (IGCC). ZONEDING helps with Clean Coal Tech. We provide machines and plans that make Coal Beneficiation efficient. This lowers the environmental impact of using coal.

Coal Gangue is a waste product from Coal Beneficiation. It can become a useful resource in different ways. You can use it to fill mines, make building materials, or generate power.

One way is to put it back into old mines. This helps make the mines stable. It also stops the ground from sinking. Another way is to turn it into building materials. You can make bricks or cement from Coal Gangue. This means we do not need to dig up as many new rocks for building. Some special power plants can even burn Coal Gangue to make electricity. This uses up waste and makes energy. By doing these things, Coal Gangue changes from a problem to something helpful. It can save money and reduce harm to the environment. ZONEDING supports smart waste handling. We provide equipment for processing and using Coal Gangue.

Regular machine maintenance is needed to keep your Coal Mining Plant running well. Regular maintenance helps prevent breakdowns, extend equipment lifespan, and improve efficiency, ensuring your plant’s success.

Regular care helps find small problems before they become big, costly breakdowns. This means less time when your machines are not working. It also helps your equipment last longer. This saves you money because you do not have to buy new machines as often. When machines are well-cared for, they also use less energy and get more work done. This means more coal processed for the same effort. Good maintenance includes: checking for hidden issues, oiling parts to reduce wear, and changing worn-out parts. ZONEDING offers full maintenance services. We also have spare parts. This keeps your Coal Mining Plant running smoothly and effectively.

Choosing the right supplier for your coal project is key to success. Look at their experience, the range of equipment they offer, customization options, service support, and what other customers say. Picking a supplier for your coal project is like choosing a trusted partner for your business. You want someone reliable, with lots of experience, and truly dedicated to helping you succeed.

Case: Colombia Coal Preparation Plant Project

A key difficulty was managing the high water content and coal slime generated by the existing plant. ZONEDING added a High Efficiency Concentrator and Dewatering Screen to improve water recycling and coal slime recovery. After implementation, the plant achieved a clean coal product with less than 10% ash content. The overall coal recovery rate increased by 8%. This project showcased ZONEDING’s ability to tackle complex design challenges. It also proved our commitment to delivering efficient and sustainable Coal Processing Plant solutions. The client was able to significantly increase their output of high-grade thermal coal. They also reduced their operational costs. This made their mining business much more profitable.

Setting up a Coal Processing Plant needs careful planning. You must know your coal, choose the right cleaning methods, and pick good equipment. Coal Preparation is important for getting clean coal. This makes coal more valuable. It also helps meet environmental rules. Think about things like types of coal, cleaning levels, and how to deal with Coal Gangue. Also, remember to plan for your investment and maintain your machines.

To start your coal project, first, understand your raw coal fully. Then, plan your process with an expert. Choose reliable equipment that can be customized. Ensure you have good maintenance in place. Finally, think about how to turn Coal Gangue into a resource. Consider partners like ZONEDING to help you with every step. We can provide the right equipment and support.

We are ZONEDING MACHINE. We are a leading manufacturer of mineral processing equipment from China. Our focus is on B2B. Since 2004, we have provided full solutions for the mining industry. We offer a wide range of products. These include crushers, grinding mills, and beneficiation equipment. We also provide drying and calcining machines. Our products are used in coal and other mineral processing jobs. We have 15 expert engineers. They ensure our designs and product quality are top-notch. Our factory is 8000 square meters. We can produce over 500 machines each year. We offer full services. This means we design, make, install, train, and support our equipment. We sell directly from the factory. This gives you competitive prices. Our products go to over 120 countries. This shows our global reach. Choosing ZONEDING means you get high-quality equipment. You also get reliable service and expert support.

Ready to start your Coal Processing Plant project? Want to upgrade your current Coal Preparation Plant? Contact us today. Our experts can give you a free consultation. We will help you find the best solution for your needs. Visit our website to learn more about our products. Get a quote now!

Last Updated: November 2024