6-S Shaking Table Installation and Maintenance

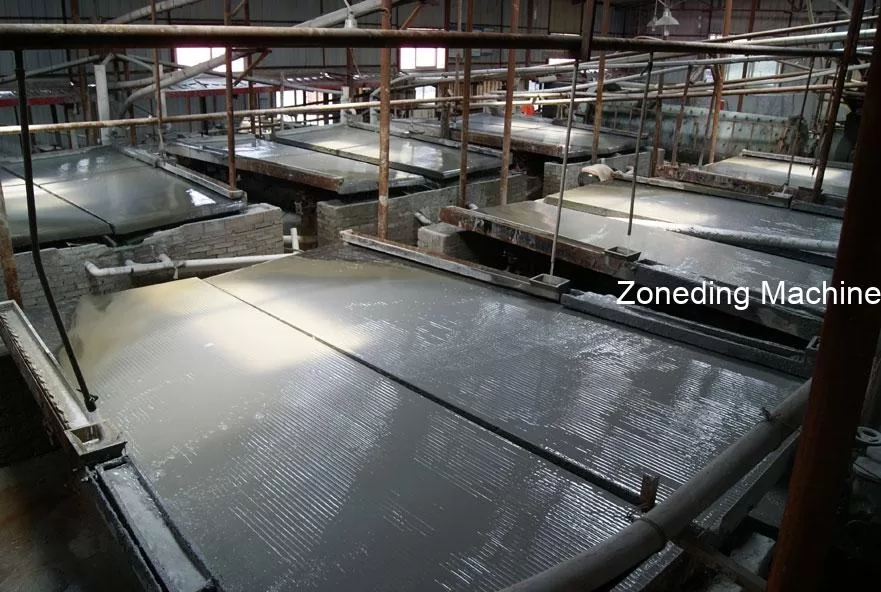

6-S Shaking Table is a gravity concentrator used for beneficiation and separation of ores. The following are general steps regarding the installation and maintenance of the 6-S Shaking Table:

Installation:

Site preparation: choose a flat and solid site to ensure that the shaking table can be installed stably. Remove obstacles and debris on the site.

Foundation Construction: Build a solid foundation according to the size and weight requirements of the shaker. The foundation should have sufficient stability and load-bearing capacity.

Installation of the frame: Install the frame of the 6-S shaker on the foundation. Make sure the frame is stable and follow the installation instructions provided by the manufacturer.

INSTALL BED TOP: Install the bed top on the shaker frame. The bed needs to be tight and level to allow for efficient ore separation and beneficiation.

Installation of transmission device: Install and connect the transmission device of the shaker, such as motor, reducer, etc., according to the instructions provided by the manufacturer.

CONNECT TO POWER SUPPLY: Connect the power cord of the shaking table to the power supply, ensuring that the voltage and current match the requirements of the equipment.

Maintenance:

REGULAR INSPECTION: Regularly inspect the various components of the shaker, including the bed surface, transmission device, motor, etc. Ensure their normal operation and tightness.

CLEANING MAINTENANCE: Clean the bed surface and the frame of the shaker regularly to remove dust, particles and impurities. Wipe with a clean cloth or brush, avoiding caustic or abrasive cleaners.

LUBRICATION AND MAINTENANCE: Lubricate and maintain the transmission of the shaker according to the requirements and recommendations provided by the manufacturer. Ensure adequate lubricant or grease and replacement intervals.

Damage Repair: If any damage or malfunction is found, repair or replace damaged parts promptly. Follow the manufacturer’s instructions or seek professional technical support.

Regular Maintenance Program: Establish a regular maintenance program, including inspection, cleaning, lubrication and repair, to ensure the continued operation and performance of the shaker.

These are general 6-S shaker installation and maintenance steps. Since specific shaker models and manufacturer’s requirements may vary, it is recommended that you refer to the specific installation and maintenance instructions provided by the manufacturer.

Zoneding Machine

Zoneding Machine