Search the whole station Crushing Equipment

You need to crush granite rock. This is a common need for many businesses. Crushing granite makes stone for buildings and roads. It changes raw rock into useful material. ZONEDING builds machines that crush rock. ZONEDING helps companies crush hard rock like granite. This article shows you how to crush granite. It tells you which machines work best. It helps you manage costs. It helps you get the right stone shape.

Last Updated: March 2025 | Estimated Reading Time: 15 Minutes

Crushing granite is harder than crushing other rocks. Think of limestone. Limestone is a soft rock. Granite is a hard rock. Granite is much harder. This hardness makes it harder to break. Granite is also very abrasive. It is like rough sandpaper. It wears down machines fast. Limestone does not wear down machines quickly.

Here are reasons granite is harder to crush:

Crushing hard granite needs strong machines. Granite’s abrasiveness means parts that touch the rock wear out fast. These are called wear parts. They include parts in Cone Crushers. Changing wear parts costs money. It also stops crushing while you change them. This means you make less stone each day. Knowing your granite’s hardness is key. Knowing its abrasiveness is key.

Granite breaks in a different way. Granite has natural cracks. These cracks can help crushing. But sometimes, these cracks make too many small pieces. This makes too much fine rock dust. You might not want this fine material.Crushing granite needs machines built for very hard materials. It needs a plan for changing worn parts often. This makes it harder than crushing soft rocks. This is why picking the right granite crushing equipment matters a lot for your work.

Not all crushing machines are good for granite. Granite is hard. It is abrasive. You need specific machines for these conditions. Picking the right crusher is important. It changes how much stone you make. It changes how long your machines last. It changes how much you spend on repairs. ZONEDING knows which machines work best for hard rock.

The best crushers for granite are built for hard rock. Here are the main ones:

Machines like Impact Crushers or Hammer Crushers are for softer rock like limestone. They hit rock with hammers.

Why these are not good for granite:

So, for granite, you start with a Jaw Crusher. Then you use one or more Cone Crushers. You might add a Sand Making Machine at the end for the best shape.

There is no single perfect machine for all granite crushing. The best machine or set of machines depends on things. It depends on how hard your granite is. It depends on how abrasive it is. It depends on what size stone you want. It depends on what shape you need the stone. It also depends on how much stone you need to make each hour. Simple truth: Match machine strengths to your rock and your product. A Jaw Crusher is great for the first big break. A Cone Crusher is great for more breaking and shaping hard rock. A Sand Making Machine is best for final shape, but wear costs are high. You must think about all these things for your granite crushing equipment.

Granite wears down Crushing Equipment fast. This is a big issue. New parts cost a lot. It also stops your work. You want to wear parts down less. There are ways to do this. Pick the right machines. Manage how you use them. Less wear means less cost for changing wear parts.

Here are ways to reduce wear:

Checking your machines often is very important. Look at the wear parts frequently. Check for loose bolts. Check the oil system. Missing small problems leads to big, costly problems. Simple rule: A little time checking saves a lot of time and money fixing big breaks. Keep notes for each machine. Write when you check it. Write what you see. Write when you change parts. This helps you guess when to change parts. It helps you order new parts early. This keeps your plant running. It stops sudden halts. This careful watch helps machines last longer. It lowers repair costs. It helps your granite crushing run well.

Making good granite aggregate for building needs more than one crusher. You must break the rock in steps. This is multi-stage crushing. Breaking rock step by step is the best way to get the right sizes and shapes of stone. It also helps machines work better. This makes a good granite crushing process flowchart.

A normal granite crushing process has steps:

Between crushing steps, use screens. Vibrating Screens sort rock by size. They have different size holes. Small rocks go through. Bigger rocks stay. This is screening.

Why screens are important:

Screening and sending big rock back to the crusher is a closed circuit. This controls final size well. This multi-stage process with screening is key for good granite aggregate.

Using a closed loop system makes better stone. In a closed loop, rock from a crusher goes to a screen. The screen sorts stone by size. Rock pieces that are the right size and shape go to storage. Rock pieces that are too big go back to the crusher. This repeats until all rock is the right size. Closed loop help: This checking and re-crushing makes sure almost all final stone is the right size. It also helps the shape. It stops you from crushing rock too much. Crushing too much wastes power. It makes dust. This method gives you good control over final stone quality. It helps you meet strict size rules for building. ZONEDING suggests closed loop for good granite work.

The shape of crushed stone matters a lot. For good concrete, asphalt, and roads, you need stone pieces like cubes. Flat or long pieces do not fit together well. They leave gaps. This makes concrete or asphalt weaker. Granite can break flat or long. This happens because of how granite is structured. Or it happens because of how it is crushed. You must work to get a good cube shape.

The crusher type changes the shape.

To get the best shape from granite aggregate, use many crushing steps. Use a Jaw Crusher first. Then use one or two Cone Crushers for the middle. A Cone Crusher in a closed loop helps shape. Flat pieces go back to be crushed more. For the best shape, add a Sand Making Machine at the end. The Sand Making Machine takes stone from the Cone Crusher. It hits stone fast. This makes more stone pieces into cubes.

Sand Making Machines make the best shape. But they wear out fast with abrasive granite. You must balance good shape with the cost of VSI wear parts. Sometimes, running the Cone Crusher carefully makes a good enough shape. Then you do not need a VSI. This choice depends on what your customers need. It depends on your plant’s money. Use screens after each step to check shape. Look at stone samples. See if you get enough cubes. Changing crusher settings can also change shape.

Every place with granite is different. The stone hardness is different. The amount of waste rock is different. The size of rocks from the mine is different. Small things about how the granite breaks are different. You must pick a granite crushing process flowchart that fits your granite. Using a process for another rock type will not work well. It will cost more money. It will make poor stone.

First, know your granite well. Get samples of your rock tested. Test it in a lab. Tests measure:

This information is your start. Important step: Test your rock carefully. This information is key for good plant design choices. Many plants have problems because they did not test rock first. ZONEDING helps clients know their rock properties.

Based on tests, pick machines and steps.

The final stone size needed is also key for design. Small sizes need more crushing steps and finer settings. Larger sizes need fewer steps and coarser settings. How much stone you need per hour (capacity) also decides machine size. More capacity needs bigger crushers, screens, and conveyors. Picking the right crushing process flowchart based on these facts makes your plant work well. It makes the stone you need.

Crushing granite makes dust. It also makes loud noise. These hurt the environment. They hurt workers’ health. You must control dust and noise. This follows environmental rules. It keeps people safe. A modern granite crushing plant must have good systems for this.

To stop dust, use systems:

To stop noise, use methods:

Environmental rules get stricter. Your plant must meet local rules for dust and noise. Paying for good dust and noise systems early is better. Fixing problems later costs more. It helps you get permission to run. It keeps workers safe. It also makes you a good neighbor. Business plus: Good environmental work helps your company image. It shows you care. ZONEDING includes dust and noise control in plant plans.

Buying crushers is a big cost. But running a granite crushing plant has other costs too. Know all these costs. This helps you plan your money. It helps you price your stone right.

Main running costs are:

Add all these costs. Then you know how much it costs to make one ton of granite aggregate. Cost tip: Wear parts and electricity are often the top two costs for crushing granite. Try hard to cut these costs. Use good machines. Plan maintenance well. Planning these costs helps your business make money. ZONEDING helps clients see likely running costs for their plant and rock type.

Having the right machines is one part. Running them the best way is another. You want your granite plant to work best. Make more stone with less work and cost. This is optimizing. Good running and fixing are key.

Here are ways to run better:

A challenge to note: Different buyers might have slightly different quality requirements. You need to adjust your process slightly depending on your customer. Producing a consistent product with high quality, batch after batch, is a sign that your plant is well-managed and efficient.

When picking granite crushing equipment, look at certain numbers. These numbers tell you what a machine can do. They tell you if it is right for your job. Looking at the right numbers helps you pick best for your granite crushing plant.

Key numbers to check:

Compare these numbers for different machines. Do not just look at one number like capacity. See how all numbers fit. Match machine specs to your granite and your goals. Selection tip: Ask the seller how the machine works with hard granite. They should show data or examples from other granite sites. ZONEDING gives detailed numbers for all its granite crushing equipment.

The way machines are placed matters. It is the plant layout. A good layout helps rock move smoothly. It saves space. It makes fixing machines easier. It makes work safer. Planning your granite crushing plant layout needs care.

Think about these when planning:

Plan space for piles of raw rock. Plan space for piles of finished stone. These piles can be big. Trucks need space to dump rock and load stone. Roads must be strong and wide. Put the control room where operators can see key machines and rock flow. Put dust control systems near dust sources. Think about wind direction. A good layout helps everything run well. It makes your granite crushing business better.

ZONEDING helps plan efficient layouts for granite crushing plants. They use computer tools to design the best flow and access. Layout detail: Good space around machines means less time fixing them. Less fixing time means more time crushing granite.

Building and running a granite crushing plant needs permission. This permission comes from government bodies. These are called environmental permits. Permits make sure you follow rules for air, water, and noise. Crushing rock affects the environment. Making dust affects air. Using water affects water. Machines make noise. Governments have rules to protect nature and people.

Permits ensure:

Getting permits takes time. You must show your plan for the plant. Show how you will meet environmental rules. You need to show how your dust control works. Show how your water system works. Show how you will reduce noise. This plan is part of the permit process. Permit reality: It is often slow. Start early. Do not build your plant without the right permits. This can stop your work. It can cost you money.

Environmental permits are serious. Rules are strict. Breaking rules can lead to fines. Or it can shut down your plant. Work with experts who know the rules in your area. ZONEDING can suggest systems for dust and noise control that help meet rules. They know about systems for managing water. Planning for environment needs early saves trouble later. It helps your granite crushing business operate legally.

How much stone do you need to make each hour? This is your required capacity (tons per hour, tph). Choosing the right capacity for your granite crushing plant is very important. If capacity is too small, you cannot meet orders. If capacity is too big, you spend too much money on machines you do not use fully.

Capacity depends on:

Start by guessing how much stone you will sell each year. Divide by working days and hours to get needed hourly capacity. Match this need to machine capacities. Each machine (Jaw Crusher, Cone Crusher, Vibrating Screen) has a capacity number. Machines must work together. The first crusher must feed enough rock to the next. All machine capacities in the line must be balanced. If one machine is too small, the whole plant runs slow.

Consider future growth. Maybe start with a smaller capacity. Design the plant layout so you can add more machines later. This saves money now. It lets you grow when your business grows. Capacity math: Undersizing costs lost sales. Oversizing costs wasted investment. ZONEDING helps calculate the right capacity needed based on your needs and mine. They suggest machine sizes that work together well. This helps your granite crushing equipment meet your business goals.

Question 1: Can I use a mobile crusher for granite?

Yes, Mobile Crushers work for granite. They have strong crushers like Mobile Jaw Crushers and Mobile Cone Crushers. These handle hard rock. Mobile crushers are good for moving the crusher near the rock.

Question 2: How often to change granite wear parts?

It changes based on your granite and how much you crush. It could be days or weeks or months for parts like jaw plates. Check wear often to know when.

Question 3: Is granite crushing dust bad?

Yes, granite crushing makes fine dust. This dust can have silica. Breathing silica dust can harm lungs over time. Controlling dust is very important for worker health.

Question 4: What’s the difference: cone crusher vs VSI for granite?

A Cone Crusher squeezes and bends rock. Good for size reduction and shaping hard rock. A Sand Making Machine hits rock fast. Mainly used to make the shape more like a cube.

Question 5: Can ZONEDING help plan the granite crushing line?

Yes, ZONEDING plans whole plants. Engineers look at your rock, your site, your stone needs. They design a full Aggregate Production Line. From start to finish. All machines and layout.

Question 6: Are used granite crushers okay to buy?

Used machines cost less to buy. But check them carefully. Look at wear parts and machine body. A bad used crusher costs much money to fix later.

Crushing granite is hard. Rock is hard and abrasive. It needs special Crushing Equipment. Jaw Crushers and Cone Crushers are usually best for main crushing. A Sand Making Machine can be for final stone shape. To cut wear, pick strong machines and parts. Feed rock carefully. Plan many crushing steps with screens to get right sizes and shapes. Use closed loops for size and shape control. Get good cube shape with a Sand Making Machine often. Pick the right process for your granite and products. Control dust and noise for safety and rules. Think about all running costs, not just machine price. Make plant work better with good training, planning, and data. When picking machines, look at capacity, rock sizes in/out, and power. Plan a good layout for rock flow and access. Get necessary environmental permits. Choose plant capacity based on need and mine supply. Think about your granite and goals.

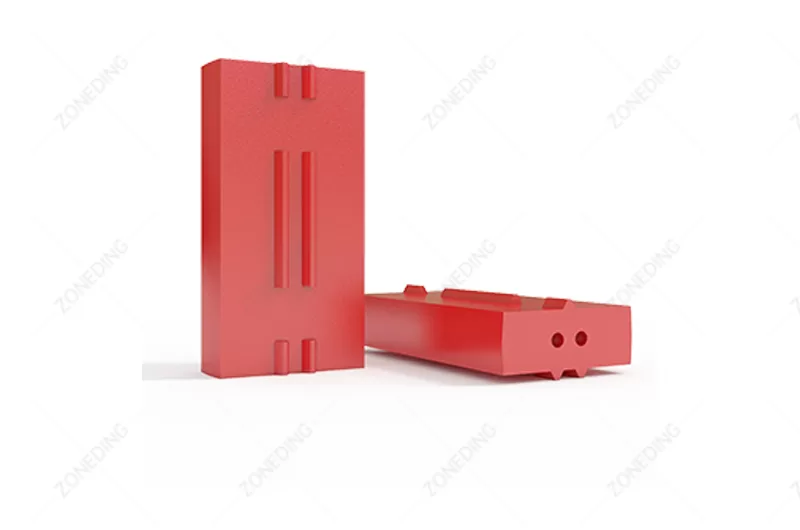

ZONEDING makes machines for crushing and processing rock. The company knows about crushing hard rock like granite. ZONEDING has many types of granite crushing equipment. This includes Jaw Crushers, Cone Crushers, Sand Making Machines, and Vibrating Screens. ZONEDING helps design a full Aggregate Production Line for your granite. The company helps you pick machines, plan your plant, install, and provides service.

If you need to crush granite, you need good equipment and advice. Contact ZONEDING. ZONEDING helps you find the best plan for your rock and needs. Contact us today to talk about your granite crushing job.

Last Updated: March 2025

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy