Search the whole station Crushing Equipment

Flotation is a common method for gold concentrators to process rock gold ore, and it is often used to process sulfide mineral gold-bearing ores with high floatability. The flotation gold process can directly discard the tailings, and at the same time consider the convenience of operation, low operating cost and maximum recovery of useful minerals.

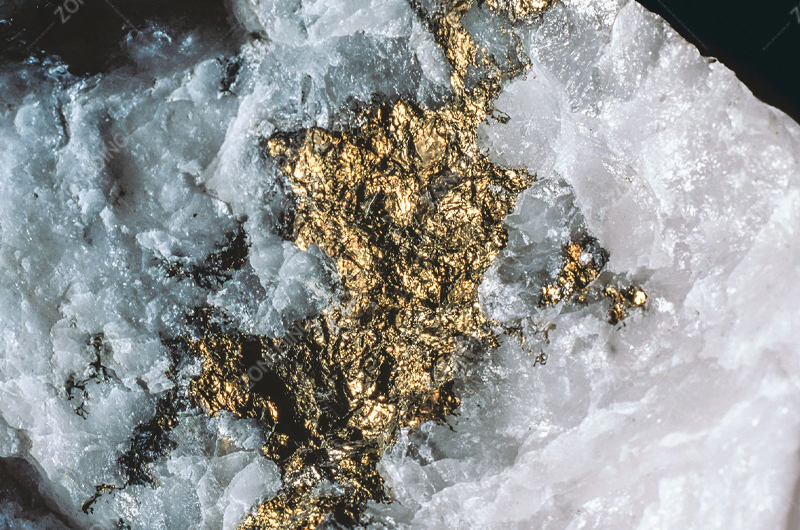

Flotation process is used to process fine gold, sulfide gold-containing quartz ore, multi metal gold-containing sulfide ore and carbon-containing ore.

You’re looking for effective ways to maximize your gold recovery. Gold flotation is a key gold processing technique, especially for certain ore types. It allows you to concentrate fine gold particles that might be lost by other methods. ZONEDING understands the nuances of gold flotation and how to optimize it for the best gold recovery rate. This guide will explain how gold flotation works, its advantages, and how to apply it to unlock more value from your gold ore.

Last Updated: March 2025 | Estimated Reading Time: 23 minutes

Gold flotation is a mineral processing technique that separates gold-bearing particles from gangue (waste rock) by making the gold or its carrier minerals hydrophobic (water-repelling) and attaching them to air bubbles. These bubbles rise to the surface, forming a froth rich in gold, which is then collected. This differs significantly from other common gold extraction methods. Gravity concentration (like using a or Spiral Chute) relies on gold’s high density to separate it. Gold cyanidation, a hydrometallurgical process, dissolves gold into a cyanide solution.

The key advantage of gold flotation lies in its effectiveness for fine, disseminated gold, particularly when gold is associated with sulfide minerals like pyrite or arsenopyrite. Gravity methods struggle with very fine gold. Cyanidation can be expensive for low-grade ores or face challenges with “preg-robbing” ores (where carbonaceous material re-adsorbs dissolved gold). Gold flotation can pre-concentrate the gold into a smaller volume of gold flotation concentrate, making subsequent cyanidation or smelting more efficient and cost-effective. It’s a crucial part of many gold processing flowsheets. ZONEDING often finds that a common misconception is that all “free” gold floats easily. In reality, the surface properties of even liberated fine gold can be altered by contamination or oxidation, making its flotation challenging without careful reagent selection and pulp chemistry control.

Gold flotation is particularly well-suited for gold ores where the gold is finely disseminated and associated with sulfide minerals. This includes sulfide gold ore flotation, where gold occurs as microscopic particles within minerals like pyrite, arsenopyrite, chalcopyrite, or pyrrhotite. In these cases, the sulfide minerals act as “carriers” for the gold. By floating the sulfides, you effectively concentrate the gold. This method is often more efficient and economical than trying to directly float the gold itself, especially if the gold is sub-microscopic or locked within the sulfide matrix.

Flotation can also be used for ores containing some fine, free (liberated) gold, though it may not be as efficient for very coarse free gold, which is better recovered by gravity methods. However, the “floatability” of free gold can be a paradox. Not all “free” gold particles readily attach to air bubbles. Their surfaces can become contaminated or coated during grinding, making them less hydrophobic. This “tarnishing” can significantly hinder their recovery by flotation. Therefore, even for ores with free gold, a combination of gravity separation for coarser gold and flotation for finer gold and sulfide-associated gold is often the optimal gold processing strategy. In some cases, fine, seemingly liberated gold shows poor flotation response until pre-treatment steps like attrition scrubbing were introduced to clean the particle surfaces.

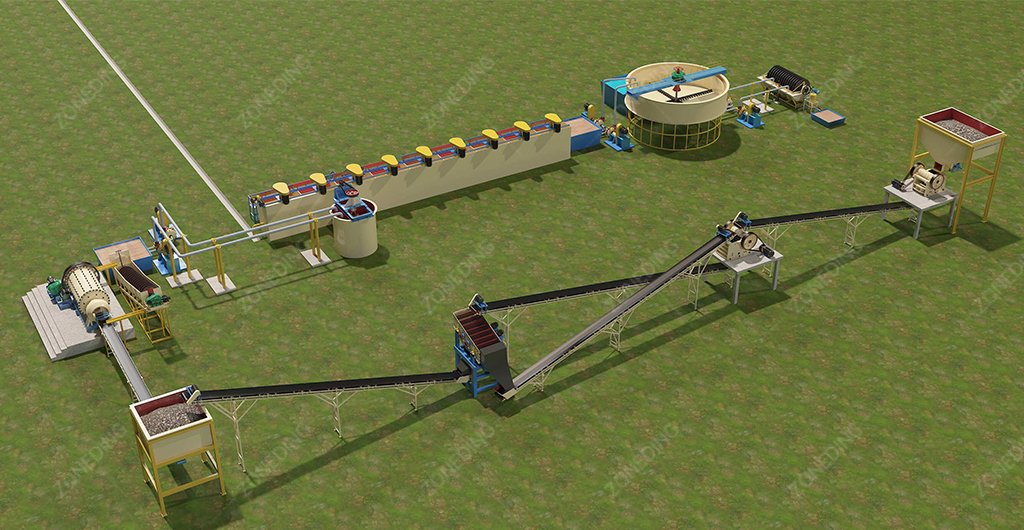

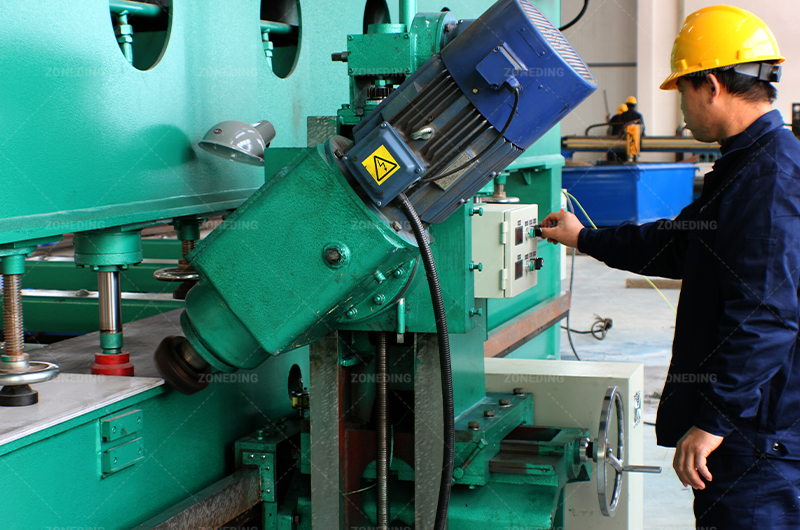

A typical gold flotation process flow involves several interconnected stages, each playing a crucial role in achieving optimal gold recovery. The process begins with comminution: crushing the run-of-mine ore using Jaw Crushers and Cone Crushers, followed by grinding, usually with Ball Mills or Rod Mills, to liberate the gold or gold-bearing sulfide particles. Proper liberation size is critical and is determined by ore mineralogy. After grinding, the ore slurry is conditioned in Mixer tanks with specific flotation reagents.

The conditioned slurry then enters a series of Flotation Machines. These are typically arranged in banks: rougher, scavenger, and cleaner stages. Rougher flotation aims to recover as much gold as possible, even at a lower grade. The tailings from the rougher stage may go to scavenger flotation to recover any remaining gold. The rougher concentrate is then usually sent to cleaner flotation stages (often multiple stages) to upgrade the gold flotation concentrate by removing entrained gangue and unwanted minerals. The final concentrate is dewatered using thickeners (like a High Efficiency Concentrator) and filters. The choice and configuration of gold ore beneficiation equipment are tailored to the specific ore characteristics and project scale. One often overlooked aspect is the strategic placement of “flash flotation” cells within the grinding circuit. These can recover liberated gold as soon as it’s freed, preventing overgrinding and surface contamination, significantly boosting overall gold recovery.

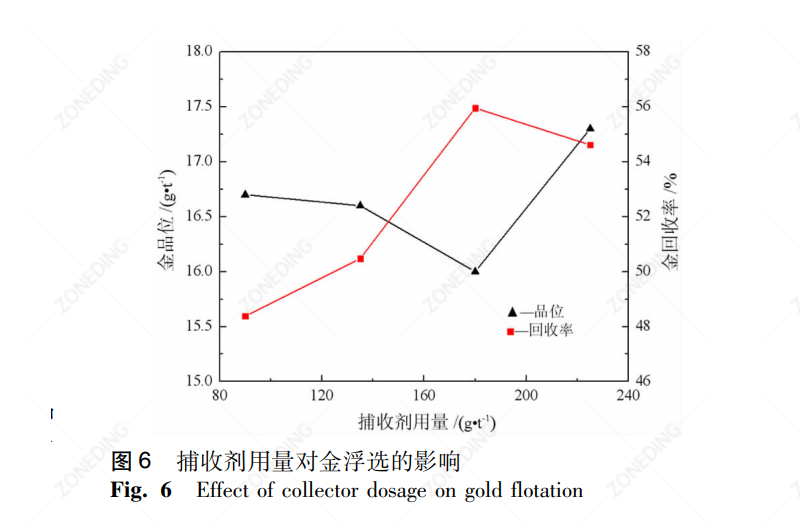

The selection and precise dosing of flotation reagents are absolutely critical to the success of gold flotation, directly impacting gold recovery and concentrate grade. There are three main types of flotation reagents used in gold processing: collectors, frothers, and modifiers. Collectors are chemicals that selectively adsorb onto the surface of gold or gold-bearing sulfide minerals, making them hydrophobic. Common collectors for gold and sulfides include xanthates (e.g., PAX, SIBX), dithiophosphates (e.g., Aero promoters), and mercaptans. The choice depends on the specific mineralogy and whether you’re targeting free gold or sulfide carriers.

Frothers (e.g., MIBC, pine oil, glycols) are added to create stable, yet suitably brittle, air bubbles that can carry the hydrophobic mineral particles to the surface. The froth structure is vital for effective collection of the gold flotation concentrate. Modifiers are used to control the pulp chemistry and enhance selectivity. These include pH regulators (like lime or soda ash to adjust alkalinity), activators (to enhance the floatability of certain minerals, e.g., copper sulfate for some gold-associated sulfides), and depressants (to prevent unwanted minerals like certain gangue or non-gold-bearing sulfides from floating). The interplay between these reagents is complex. For example, the pH significantly affects collector adsorption and the behavior of many minerals. You should notice that “more is not always better” with reagents. Overdosing can lead to non-selective flotation, poor froth characteristics, and increased costs. Careful laboratory testing and plant optimization are essential to find the optimal reagent suite and dosages for your specific ore.

Several core process parameters must be carefully controlled and optimized to maximize gold recovery rate and the grade of your gold flotation concentrate. Particle size is paramount; the ore must be ground finely enough to liberate the gold or its carrier minerals, but overgrinding can create slimes that hinder flotation. Pulp density (solids percentage in the slurry) affects reagent consumption, retention time, and bubble-particle collision efficiency. The pH of the pulp is crucial as it influences the surface charge of minerals and the effectiveness of flotation reagents, particularly collectors and depressants.

Reagent dosage and conditioning time are also key. Insufficient collector means poor hydrophobicity, while too much can lead to non-selective flotation. Adequate conditioning time allows reagents to properly interact with mineral surfaces. Aeration rate and froth depth in the Flotation Machines control the bubble generation and the selectivity of the froth collection. A less commonly discussed but highly influential factor is the electrochemical potential (Eh or ORP) of the pulp. For sulfide gold ore flotation, the Eh can significantly impact the surface chemistry of sulfide minerals and the effectiveness of certain collectors. Managing the “carrier minerals” for gold is another layer. If gold is hosted in pyrite, you need to float pyrite efficiently. But if there are multiple sulfide species, some barren of gold, you need to selectively float only the gold-bearing ones, which requires precise control of depressants and activators.

Refractory gold ores, such as those containing carbonaceous material (“preg-robbing” ores) or finely disseminated gold in arsenical sulfides, present significant challenges for gold flotation and require special processing strategies. Carbonaceous material can adsorb dissolved gold if any pre-cyanidation occurs, or it can float non-selectively, diluting the gold flotation concentrate and consuming reagents. For these ores, strategies include: pre-flotation of carbon (carbon scalping), using blinding agents (like kerosene or specialized polymers) to passivate the carbon surface before gold flotation, or employing a flotation-roast-leach sequence.

Arsenical gold ores, where gold is often locked within arsenopyrite or other arsenic-bearing sulfides, require effective flotation of these carrier minerals. However, arsenical concentrates can incur penalties from smelters or require specialized downstream processing like pressure oxidation (POX) or bio-oxidation before gold cyanidation. Fine-grained gold, whether free or encapsulated, demands very fine grinding for liberation, which can lead to slime issues. In such cases, techniques like ultra-fine grinding followed by flotation, or specialized flotation cells designed for fine particles, might be necessary. The management of “carrier minerals” is critical. It’s not just about floating any sulfide; it’s about selectively floating the gold-bearing sulfides while depressing barren ones. This requires detailed mineralogical knowledge and tailored flotation reagent schemes, possibly involving multiple stages of differential flotation.

Gold flotation concentrate typically requires further processing to extract the elemental gold, as the gold is still often encapsulated or not in a pure, saleable form. The choice of post-treatment depends on the nature of the concentrate (e.g., free gold content, sulfide association, presence of refractory components) and economic considerations. A common route for sulfide-rich gold flotation concentrate is gold cyanidation. The concentrate is reground (if necessary) and then leached with a dilute cyanide solution to dissolve the gold. The gold is then recovered from the pregnant leach solution by methods like Carbon-In-Pulp (CIP), Carbon-In-Leach (CIL), or Merrill-Crowe precipitation.

If the concentrate is highly refractory (e.g., gold locked in arsenopyrite or significant preg-robbing carbon), pre-treatment before cyanidation is often essential. This can include roasting (to oxidize sulfides and carbon), pressure oxidation (POX), or bio-oxidation. Roasting converts sulfides to oxides and burns off carbon, liberating the gold for subsequent leaching, but it generates SO2 gas that must be managed. POX and bio-oxidation are hydrometallurgical methods that break down the sulfide matrix under specific conditions. In some cases, particularly for very high-grade concentrates with coarse free gold, direct smelting might be an option, though this is less common. The overall goal is to select a post-treatment method that maximizes gold recovery economically and environmentally.

Investing in a gold flotation circuit involves specific gold ore beneficiation equipment and ongoing operating costs that you need to carefully consider. The main equipment includes crushing units (Jaw Crushers, Cone Crushers), grinding mills (Ball Mills), conditioning tanks (Mixers), banks of Flotation Machines (roughers, scavengers, cleaners), thickeners, filters, and reagent preparation/dosing systems. The scale of operation (tonnes per day) will largely dictate the size and number of these units, directly impacting capital expenditure (CAPEX).

Operating costs (OPEX) for gold flotation primarily consist of:

The “hidden cost” of poor carrier mineral management can also inflate OPEX. If you’re floating large quantities of barren sulfides along with the gold-bearing ones, you’re wasting reagents, power, and downstream capacity on material that doesn’t contribute to your gold recovery rate. Optimizing selectivity is key to managing these costs effectively.

Laboratory amenability testing is a crucial first step to determine if your gold ore is suitable for gold flotation and to develop a preliminary processing flowsheet. These tests provide vital data on potential gold recovery, concentrate grade, reagent consumption, and identify any processing challenges. The testing typically starts with detailed ore characterization: chemical assays (gold, silver, sulfur, arsenic, carbon, etc.) and mineralogical analysis (QEMSCAN, XRD, microscopy) to identify gold deportment (how gold occurs – free, encapsulated, grain size) and associated minerals.

Flotation tests are then conducted on representative ore samples. These batch tests explore various parameters:

Locked cycle tests (LCTs) simulate a continuous circuit by recycling intermediate streams, providing a more realistic estimate of plant performance. The results will indicate the achievable gold recovery rate and gold flotation concentrate quality. These tests also help identify issues like preg-robbing or the presence of difficult-to-float gold. For instance, the behavior of “free gold” in flotation is often counterintuitive. Lab tests can reveal if fine, liberated gold is being lost due to surface contamination, requiring specific pre-treatment or specialized collectors.

Maximizing your return on investment (ROI) in a gold flotation project hinges on several key factors, extending beyond just purchasing gold ore beneficiation equipment.

Effective process control and automation can lead to more stable operation and higher gold recovery. Investing in good instrumentation and skilled operators pays dividends. A critical factor, often underestimated, is the management of “carrier minerals.” If your gold is hosted in specific sulfides, ensure your flotation circuit is optimized to recover those sulfides selectively, not just bulk sulfides. This avoids diluting your gold flotation concentrate and reduces downstream processing costs. Finally, consider the entire value chain, including concentrate transportation, smelting/refining terms, and environmental compliance. A holistic approach that balances CAPEX, OPEX, gold recovery rate, and risk management will ultimately ensure the best ROI for your gold flotation venture.

Question 1: Can gold flotation recover 100% of the gold from an ore?

No, 100% gold recovery is practically impossible. The achievable gold recovery rate depends on ore mineralogy, liberation, particle size, and process efficiency. Typical recoveries can range from 70% to over 95% for suitable ores.

Question 2: What is the main difference between a gold collector and a frother?

A collector makes gold or gold-bearing mineral particles hydrophobic (water-repelling) so they attach to air bubbles. A frother helps create stable air bubbles that carry these mineral-laden bubbles to the surface to form a collectable froth.

Question 3: Why is pH important in gold flotation?

pH affects the surface charge of minerals and the ionization/effectiveness of many flotation reagents, especially collectors. Optimizing pH is crucial for selective flotation and maximizing gold recovery.

Question 4: How is preg-robbing carbon handled in gold flotation?

Strategies include pre-floating the carbon before gold flotation, using blinding agents (like kerosene) to deactivate the carbon, or employing specialized leaching circuits (like CIL/CIP) if flotation is followed by cyanidation.

Gold flotation is a powerful and widely used gold processing technique essential for maximizing gold recovery from many ore types, especially those with fine, disseminated gold or gold associated with sulfides. Success depends on understanding your ore, selecting the right flotation reagents, optimizing process parameters, and choosing appropriate gold ore beneficiation equipment. Addressing challenges like refractory ores and managing operating costs are key to a profitable operation. The journey to a high gold recovery rate involves careful planning, testing, and continuous optimization.

If you are considering gold flotation for your project, start with comprehensive metallurgical testing. This will lay the groundwork for a successful and profitable venture. ZONEDING is dedicated to providing efficient and tailored solutions for your gold flotation needs.

ZONEDING is your expert partner for a full range of mineral processing equipment and complete gold processing solutions. ZONEDING specializes in gold flotation technology, providing everything from Jaw Crushers and Ball Mills to state-of-the-art Flotation Machines and concentrate handling systems. Our experience spans global projects, offering flowsheet design, equipment supply, installation, commissioning, and ongoing support to help you achieve the highest possible gold recovery and operational efficiency.

Contact ZONEDING’s specialists today to discuss your gold project and let us help you turn your ore into gold!

Last Updated: March 2025