What are the 5 essential crusher types for mineral processing?

3837Maximize efficiency in mineral processing! Uncover performance of five key crusher types, optimized for throughput, energy, and cost-saving ore reduction.

View detailsSearch the whole station Crushing Equipment

Planning a project requires a budget, but asking for a single ball mill price is the wrong place to start. A price tag without context is misleading. The “cheapest” mill often becomes the most expensive one to operate.

A ball mill is not an off-the-shelf product; it is a custom-engineered system. The ball mill cost depends on ore characteristics, capacity, and component quality. For 2025, expect a range from $40,000 for a small mill to over $1,500,000 for a large one, before key components.

The initial price of the steel drum is only a fraction of the total investment. A true ball mill budget must account for the drive system, wear parts, and operational efficiency. This guide provides a framework for understanding the real cost drivers and for securing a comprehensive ball mill quotation.

It can be frustrating. A simple request for a price is met with a list of questions. This isn’t a delay tactic. It’s a critical step to protect the buyer’s investment from failure.

Professional ball mill manufacturers ask detailed questions to engineer a machine that will perform efficiently and reliably. Without understanding the material, capacity, and size requirements, any price given is just a guess that could lead to a costly mistake.

These five questions are the foundation of a correct mill specification.

A low price might look attractive, but it could be missing critical components. An incomplete quotation creates a risk of unexpected expenses that can completely derail a project budget.

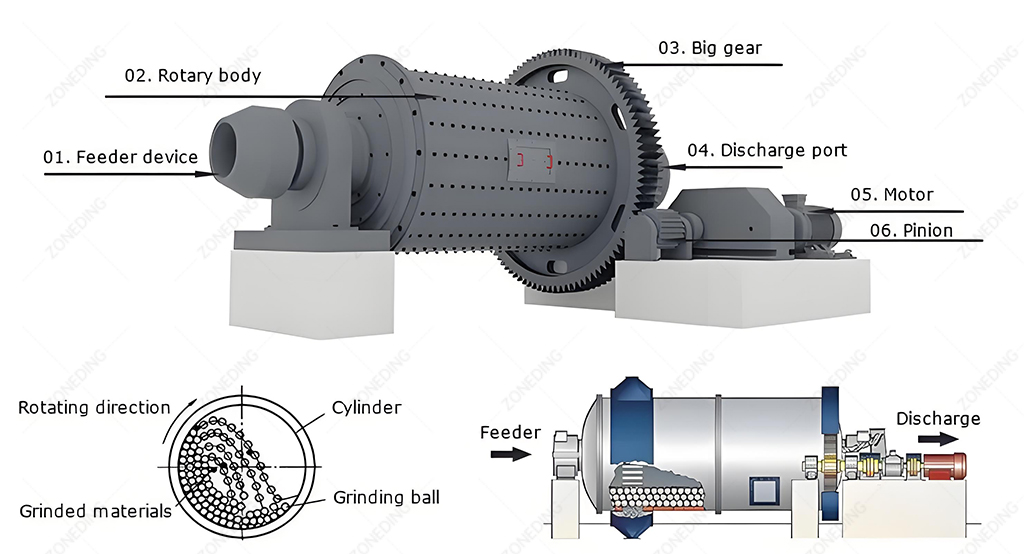

A complete ball mill quotation must detail more than just the mill shell. It should clearly specify the entire drive system (gear, pinion, motor), the bearing assemblies, the lubrication system, and the liner package. Grinding media is typically quoted separately.

A professional quote from a reputable ball mill supplier should be transparent and itemized.

Receiving two quotes for mills of the same size with vastly different prices is confusing. It’s easy to assume one supplier is simply overcharging. The reality is that the difference lies in the unseen quality of critical components.

The ball mill price for a given capacity can double based on the specification of its liners, motor, and drive system. Premium, long-life components have a higher upfront cost but result in a lower total cost of ownership through reduced downtime and maintenance.

Three key areas account for the largest price variations.

| Component | Standard (Lower Price) Option | Premium (Higher Price) Option | Impact on Performance |

|---|---|---|---|

| Liners | High-Manganese Steel | Rubber or High-Chrome Alloy | Premium liners can last 2-4 times longer in abrasive applications, drastically reducing downtime for relining. |

| Main Motor | Generic Brand, Standard Efficiency | Siemens/ABB, High Efficiency (IE3/IE4) | A high-efficiency motor costs more but saves thousands in electricity costs over its lifetime. Premium brands offer better reliability. |

| Drive Gear | Standard Casting Process | High-Standard Casting (e.g., AGMA), Documented QC | A poorly made gear will fail prematurely, causing a catastrophic shutdown. A high-quality gear is an insurance policy for uptime. |

While a final price requires a detailed specification, having a starting point for budget discussions is essential. These figures provide an order-of-magnitude estimate for planning purposes.

For a standard mining ball mill from a reputable Chinese supplier in 2025, a small-scale mill may cost $40k-$75k, a mid-size production mill $250k-$450k, and a large-scale mill $800k-$1.5M+. These are FOB prices for the base machine.

This table provides estimates for a standard wet-grinding overflow ball mill.

| Category | Typical Specs (Diameter x Length) | Motor Power (Approx.) | Estimated Price Range (USD) |

|---|---|---|---|

| Small / Pilot Scale | 1.2m x 2.4m | 30-45 kW | $40,000 – $75,000 |

| Mid-Size Production | 2.7m x 4.0m | 400-500 kW | $250,000 – $450,000 |

| Large Production | 4.0m x 6.0m | 1,500-1,800 kW | $800,000 – $1,500,000 |

| X-Large Scale | 5.5m x 8.5m | 4,500-5,000 kW | $2,500,000 – $4,000,000+ |

| Disclaimer: These are estimates for the base mill assembly (shell, liners, gear, bearings). They exclude the motor, drive electronics, grinding media, shipping, insurance, and installation, which are all significant additional costs. |

An unbelievably low price is a major red flag. While sourcing from China can offer a cost advantage, some prices are low because corners have been cut in ways that are not immediately visible.

Extremely low ball mill prices often indicate the use of substandard materials, a lack of quality control, non-existent after-sales support, or that the quote is from a trading company, not a true manufacturer. These hidden compromises lead to higher long-term costs.

Be vigilant for these potential traps when a price seems too good to be true.

To move from a budget estimate to a firm, reliable quotation, the supplier needs specific data. Providing comprehensive information upfront streamlines the process and ensures the final quote is accurate.

To get a precise and reliable ball mill quotation, a buyer must provide a complete set of technical specifications. This includes detailed information about the ore, the process, and the production goals.

Prepare this checklist before contacting a supplier.

Building a reliable ball mill cost budget involves more than asking for a price. It requires understanding the technical factors that drive cost and performance. A well-specified mill from a reputable supplier like ZONEDING is a profitable long-term investment.

Maximize efficiency in mineral processing! Uncover performance of five key crusher types, optimized for throughput, energy, and cost-saving ore reduction.

View detailsOur guide to the andesite crushing process, from rock properties to plant design. Learn to select the right jaw & cone crushers for high efficiency.

View detailsThe selection of mineral processing dewatering equipment determines the final moisture of your product and waste. Removing water correctly lowers your transport costs and protects the environment. This guide provides a full overview of the dewate...

View detailsAlluvial gold washing often fails when sticky clay exists in the ore. This clay creates mud balls that trap gold particles and carry them into the waste piles. Breaking these mud balls requires high-energy mechanical force and specific equipment....

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy