What Machinery is Used in Quartz Sand Production?

3897Discover essential machinery applied in a quartz sand processing line. Learn about crushers, washers, screens and separators for high purity sand production.

View detailsSearch the whole station Crushing Equipment

Choosing between an impact crusher and a hammer crusher is a common point of confusion. They look similar—a spinning rotor in a box—but they are as different as a scalpel and a sledgehammer.

The main difference is their crushing philosophy. An Impact Crusher “throws” material to create a superior, cubical shape. A Hammer Crusher “smashes” material with brute force for high reduction, sacrificing shape.

Making the wrong choice for your application is a costly mistake. An impact crusher acts like a high-speed slingshot, breaking rock along its natural lines of weakness. A hammer crusher acts like a grinder, pulverizing material against grate bars. As a manufacturer, I will explain the differences that a spec sheet will never tell you.

You need to produce high-quality aggregate for concrete or asphalt. Your customers demand a good, cubical particle shape. You cannot afford to produce flaky or elongated stone.

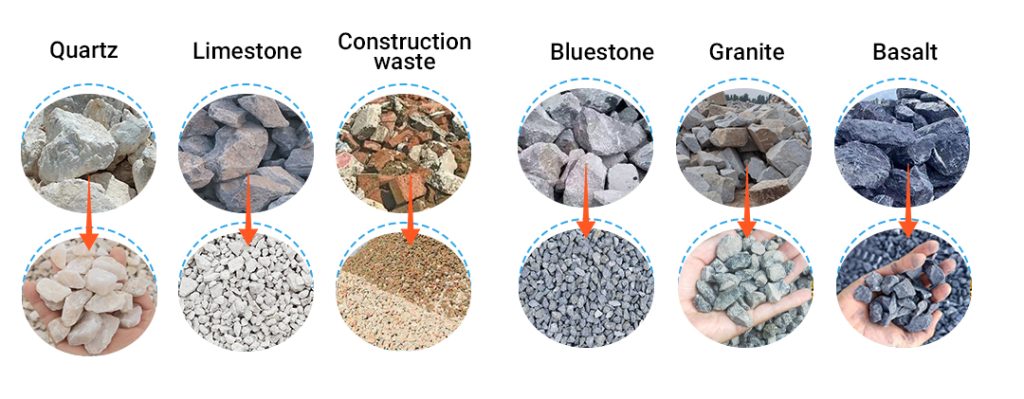

An Impact Crusher is best for medium-hard, non-abrasive materials like limestone, dolomite, and basalt. Its top application is in concrete and asphalt recycling, where it creates a premium cubical product.

This is the million-dollar difference for aggregate producers. The impact crusher’s mechanism is key.

The rotor has heavy blow bars that strike the rock and hurl it at high speed against stationary impact plates. The rock shatters along its natural weak points from this collision. This “throwing” action is what produces a superior aggregate shape.

Its ability to produce cubical aggregate makes it the top choice for secondary crushing in quarries. It also excels at construction waste crushing. Its design can liberate rebar from concrete effectively. For these jobs, a Mobile Impact Crusheroffers ultimate flexibility.

| Material | Impact Crusher Suitability |

|---|---|

| Limestone, Dolomite | Excellent (Primary Application) |

| Basalt (low silica) | Good |

| Concrete & Asphalt Recycling | Excellent |

| Granite, River Gravel | Poor (High Wear Cost) |

You need to process softer or stickier materials. Your main goal is high size reduction, not perfect particle shape. You might be producing raw material for a cement plant or grinding industrial minerals.

A Hammer Crusher (or hammer mill) excels with softer, more friable, or sticky materials like coal, gypsum, phosphate rock, and bauxite. It’s chosen when a high reduction ratio is the priority.

The hammer crusher’s design is all about brute force and controlled sizing.

The rotor is fitted with swinging hammer heads. These hammers smash the material directly and drag it against a breaker plate and grate bars. This action smashes, shears, and pulverizes the material until it is small enough to pass through the grate openings.

This machine is a workhorse in industries where final shape is not the main concern. It’s used for preparing raw meal for cement, crushing coal for power plants, and processing various softer industrial minerals. It is not suitable for hard, abrasive rock due to very high wear parts cost.

| Material | Hammer Crusher Suitability |

|---|---|

| Coal, Gypsum, Bauxite | Excellent |

| Limestone (for cement) | Excellent |

| Glass, Agricultural Lime | Good |

| Abrasive Rock | Poor (Extreme Wear Cost) |

Your production is constantly stopping because wet, sticky material is building up and choking your crusher. This downtime is killing your profitability and causing major frustration for your operators.

An impact crusher is much better for wet, sticky materials. Its open-discharge design prevents clogging, while the grate bars in a hammer crusher can easily get plugged, causing a complete stoppage.

This is one of the most important practical differences in crusher selection.

An Impact Crusher has no screen or grate at the bottom. The crushed material falls freely out of the chamber. This open design makes it very difficult for sticky material to build up and cause a blockage. It keeps running when other machines would have stopped.

A Hammer Crusher relies on its grate bars to control the product size. When processing wet material crushing, the fine, sticky particles can quickly build up and blind the openings in the grate. This completely stops the flow of material, choking the crusher and forcing a shutdown for cleaning.

| Feature | Impact Crusher | Hammer Crusher |

|---|---|---|

| Discharge Design | Open, Free-Flow | Grate-Controlled |

| Wet/Sticky Material | Handles Well | High Risk of Clogging |

| Downtime Risk | Low | High |

You do not care about particle shape. You just want to take your material and make it as fine as possible in a single machine to simplify your process.

Yes, a hammer crusher can achieve a much higher reduction ratio and produce a finer output size in a single pass. This is because its grate bars ensure no material exits until it is small enough.

This capability is a core design feature, but it’s not a simple case of “finer is better.”

The combination of direct smashing and the positive sizing of the grate bar system allows a Hammer Crusher to achieve reduction ratios of 30:1 or more. It can effectively turn small stones into a sand-like product in one step, which is why it is popular for certain specific applications like cement raw meal preparation.

An Impact Crusher has a good reduction ratio, typically around 10:1 to 20:1. It is designed to be a secondary crusher. Forcing it to produce an ultra-fine product by tightening the gaps and increasing the speed is highly inefficient. It dramatically increases the wear parts cost and energy consumption.

You are crushing demolished concrete. Your biggest worry is a piece of rebar getting into the crusher and causing catastrophic damage, leading to expensive repairs and long downtime.

The impact crusher is the only safe and effective choice for crushing concrete with rebar. Its large, robust chamber and heavy blow bars can liberate the rebar from concrete without destroying the machine.

This is a critical safety and operational consideration in construction waste crushing.

An Impact Crusher shatters the concrete around the rebar. The rebar is then discharged along with the crushed aggregate, where it can be easily removed by a magnet. The machine is designed to handle this. For this application, a Tracked Impact Crusher provides the mobility needed on demolition sites.

Feeding rebar into a Hammer Crusher is a recipe for disaster. The swinging hammer heads will get caught on the rebar, which can lead to broken hammers, a damaged rotor, and a destroyed discharge grate. The machine is not designed to handle tramp metal of this size and strength.

| Feature | Impact Crusher | Hammer Crusher |

|---|---|---|

| Handles Rebar? | Yes, effectively liberates it | No, high risk of damage |

| Suitability for C&D Waste | Excellent | Very Poor / Dangerous |

| Typical Setup | Crusher + Magnet | Not Applicable |

You are looking at prices, and the hammer crusher seems like a bargain. You are tempted to save money on the initial purchase, but you are worried about the long-term costs.

Yes, this can be a classic cost trap. A hammer crusher has a lower initial price, but if used on the wrong material, its operating cost for wear parts will be many times higher than an impact crusher.

Never make a crusher selection based on purchase price alone. You must consider the Total Cost of Ownership (TCO).

A Hammer Crusher is a simpler machine and is often built lighter. This results in a lower initial purchase price. An Impact Crusher is a heavier, more robust machine designed to handle higher dynamic forces, so its upfront cost is higher.

This is where the real story is. In a typical limestone aggregate application, the wear parts cost for a hammer crusher (hammers and grates) can be 3 to 5 times higher than for an impact crusher (blow bars and impact plates). The cheap initial purchase is quickly erased by constant maintenance and parts replacement. The TCO almost always favors the machine that is correctly chosen for the application.

| Cost Factor | Impact Crusher | Hammer Crusher |

|---|---|---|

| Initial Purchase Price | Higher | Lower |

| OpEx (Abrasive Rock) | High | Extremely High |

| OpEx (Soft Rock) | Low | Low |

The choice is clear if you know your goal. An impact crusher creates value through superior shape. A hammer crusher creates value through high reduction. Choosing the right machine is key to profitability.

Discover essential machinery applied in a quartz sand processing line. Learn about crushers, washers, screens and separators for high purity sand production.

View detailsThe right ball mill depends on your application. We compare wet and dry grinding for mining, cement, and ceramics to help you select the most efficient and effective solution.

View detailsDesign a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsLearn how magnetic separation uses magnetism and froth flotation uses surface chemistry, plus see their key applications.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy