Alluvial Gold Processing Plant: A Complete Guide

3526Choosing the right alluvial gold equipment is crucial. Compare trommel screens, jigs, and shaking tables to build an efficient processing line for max recovery.

View detailsSearch the whole station Crushing Equipment

You are trying to select a flotation machine, but the different model numbers and designs can be confusing. Choosing the wrong type of cell can lead to poor recovery, sending valuable minerals straight to the tailings pond.

The primary difference between flotation machine models is their method of air induction and slurry agitation. Models are designed to create specific hydrodynamic conditions suitable for different particle sizes and stages within the flotation process, such as roughing, cleaning, or scavenging.

To the untrained eye, they all look like tanks that mix slurry. But to an experienced metallurgist, a flotation circuit is a finely tuned instrument. Each cell model has a specific purpose. As a flotation machine manufacturer, we design these machines to solve specific challenges in mineral separation. This guide will clarify the key differences, helping you understand which model is the right tool for your job.

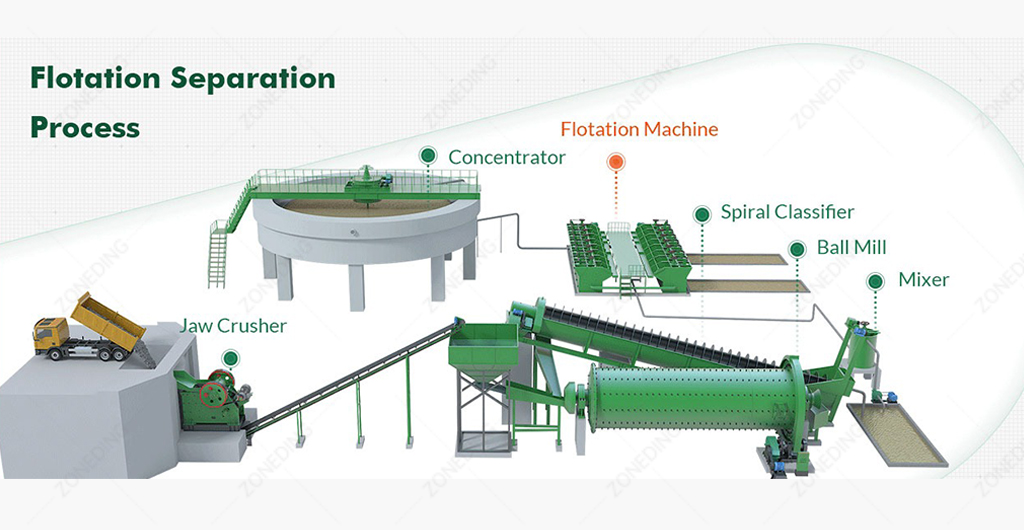

Different models of flotation machines have variations in their structure and application.

Here are the main differences:

These models may have additional specific features or variations depending on the manufacturer. Users should consider factors such as energy efficiency, slurry handling capacity, and application requirements when selecting the appropriate flotation machine for their needs.

The type of ore you are processing has a huge impact on machine selection. The size, density, and liberation characteristics of your valuable minerals dictate the hydrodynamic environment they need to float successfully.

Choosing the right machine for your ore is critical to recovery. You must match the machine’s mixing intensity and aeration characteristics to the physical properties of your mineral particles.

For coarse, heavy mineral particles (like some lead or copper ores), you need a cell with high agitation power to keep them suspended. For fine, slow-floating minerals (like some gold or molybdenum ores), you need a cell with gentle mixing and excellent fine bubble dispersion.

As a manufacturer of beneficiation equipment, we help clients make this choice every day.

A flotation circuit is not a single step; it is a multi-stage process. Each stage—roughing, cleaning, and scavenging—has a different objective. The machine design must reflect that objective.

Different stages of the flotation process have conflicting goals. Machine models are specialized to meet these specific goals, from maximizing recovery in roughers to maximizing grade in cleaners.

Rougher cells are designed for high recovery and fast kinetics to capture as much valuable mineral as possible. Cleaner cells are designed for high selectivity and grade, using features like deep froth beds to wash out impurities. Scavenger cells are designed to recover the last remaining particles, often handling a coarser feed.

Using the right machine in the right position is key to an efficient flotation process.

| Stage | Primary Goal | Required Machine Characteristics |

|---|---|---|

| Roughing | Maximize mineral recovery | High capacity, strong slurry circulation, fast froth removal, good for a wide particle size range. Large-volume forced-air cells are common. |

| Cleaning | Maximize concentrate grade | Excellent selectivity, stable and deep froth beds to allow for washing, gentle agitation to prevent entrainment of gangue. Smaller forced-air cells with good level control are ideal. |

| Scavenging | Recover remaining minerals | Strong agitation to float coarse or slow-floating particles that were missed in the rougher stage. Robust, high-power machines are often used here. |

The initial purchase price of a flotation cell is only one part of the equation. The Total Cost of Ownership (TCO) is dominated by ongoing operational costs. Different models can have vastly different TCO profiles.

The differences in operational costs between models can be enormous. A machine’s design directly impacts its power consumption, the wear rate of its components, and its efficiency in using expensive reagents.

Forced-air cells are typically more energy-efficient per cubic meter than self-aspirating cells. Wear on the impeller and stator is the largest maintenance cost, and their design and material composition are critical. An efficient cell with good mixing can also reduce reagent consumption.

At ZONEDING, we design our machines to minimize these long-term costs.

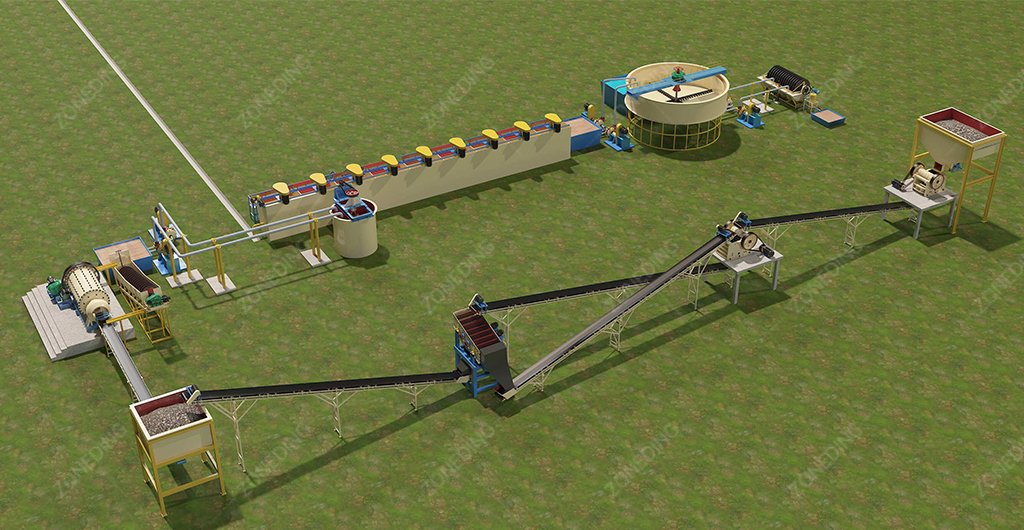

A single type of flotation cell is rarely the best solution for an entire circuit. The most effective mineral processing plants use a combination of different models, leveraging the specific strengths of each.

You cannot build a truly optimized flotation circuit with just one type of machine. The best practice is to combine different models to create a “hybrid” circuit that matches the machine to the specific task at each stage.

A common and highly effective strategy is to use a suction-type cell (like our XCF model) at the head of a flotation bank, followed by a series of standard forced-air cells (like our KYF model). This design eliminates the need for feed pumps between banks.

This is an example of smart circuit design.

The differences between flotation machine models are based on fundamental engineering principles. By understanding these differences, you can build a circuit that maximizes your recovery and profitability. Contact us to discuss your specific ore and process goals.

Choosing the right alluvial gold equipment is crucial. Compare trommel screens, jigs, and shaking tables to build an efficient processing line for max recovery.

View detailsThis expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View detailsJaw crusher components and functions determine the efficiency of primary crushing in mining and construction. This manual details the mechanical structure, material choices, and design variations of modern machines. It answers specific questions ...

View detailsLearn various methods for separating antimony ore, including gravity separation, flotation, magnetic separation. Improve your antimony recovery process today!

View details