High Frequency Screen

Applied Material:nIron ore, tin, tungsten, tantalum, niobium sand and other concentrator screening or grading operations, also suitable for mineral processing, coal processing, chemical industry, brick making, food, pharmaceutical, alkali production, chemical fertilizer, paper making and other industries.- Power:0.72-2.2KW

- Capacity:15–48TPH

The Introduction of High Frequency Screen

The Applition Fields of High Frequency Screen

The high frequency screen has several performance characteristics that make it an efficient and effective screening equipment:

The working principle of the high frequency screen involves the controlled and classified screening of grinding products.

Here are the regulations on production safety and the steps to follow in the instruction manual of a high frequency screen:

Regulations on production safety:

Preparation before driving:

High Frequency Screen Manufacturer

General Specification

| Specification Model | Processing capacity(t/h) | Power (kw) |

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |

Related Products

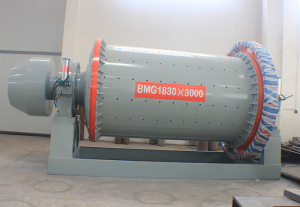

Ball Mill

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Rod Mill

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

Ceramic Ball Mill

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Flotation Machine

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

Magnetic Separator

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Jigging Separator Machine

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet Pan Mill

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking Table

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Hydrocyclone

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine