Search the whole station Crushing Equipment

Lignite Dryer is a key equipment for Lignite drying process.Lignite is a low-grade coal with a low degree of coalification, with colors like brown and dark brown and a lack of cohesion. It has properties between peat and bituminous coal, with high water content, high volatility, low density, and a high oxygen content that makes it prone to fragmentation and spontaneous combustion.

Lignite dryer machine is a kind of rotary equipment for dewatering lignite coal. Lignite dryer is brown coal dryer and wood coal drying machine, which can realize continuous, industrial and automatic operation. It comes according to lignite characteristics. Zoneding lignite dryer was born with aim to meet environmental legislation and customers’ need.

To guarantee the quality of lignite and coal slime unchanged after the drying process, Zoneding engineers keep researching and have developed advanced lignite drying technology. Zoneding focuses on controlling the scorching wind temperature and rotating speed to reach higher drying efficiency. Lignite coal dryer machine can dewater the coal slime to the moisture content below 13%, and improve the combustion efficiency.

Lignite is a kind of mineral coal with minimum coalification degree. Because it is rich in volatile elements, it is easy to burn and generate smoke. Besides, lignite contains about 6-19% ash, which makes it pollute the environment a lot when burning. Therefore, washing process can improve the purity.

Lignite is a soft, brownish-black coal that represents the youngest stage of coal formation. While abundant worldwide, it includes two key drawbacks:

These factors make raw lignite an inefficient, low-value fuel.

Drying lignite is not just about removing water; it’s about fundamentally upgrading the material.

In addition to this physical characteristic, it is of high moisture and easy to self-ignite, which is a big issue for storage and transportation. Sometimes, good coal cannot meet the fuel requirement, for which lignite is in large demand as an alternative.

In view of the above, lignite drying machine become requisite. Dried lignite is in thermal power plant, chemical industry, metal recycling as well as catalyst supports, adsorbents, sewage purification etc. And the lignite dryer machine can also apply for drying fly ash, coke, coal as well as other granular, paste and powder materials.

The applications for lignite depend entirely on whether it has been dried. Raw, high-moisture lignite is almost exclusively used for one purpose: steam-electric power generation in power plants built directly at the mine site (“mine-mouth” plants). Its high water content makes it uneconomical to transport anywhere else. However, once the lignite is dried and upgraded, its applications expand dramatically. This stable, high-energy product can be sold and transported for use in:

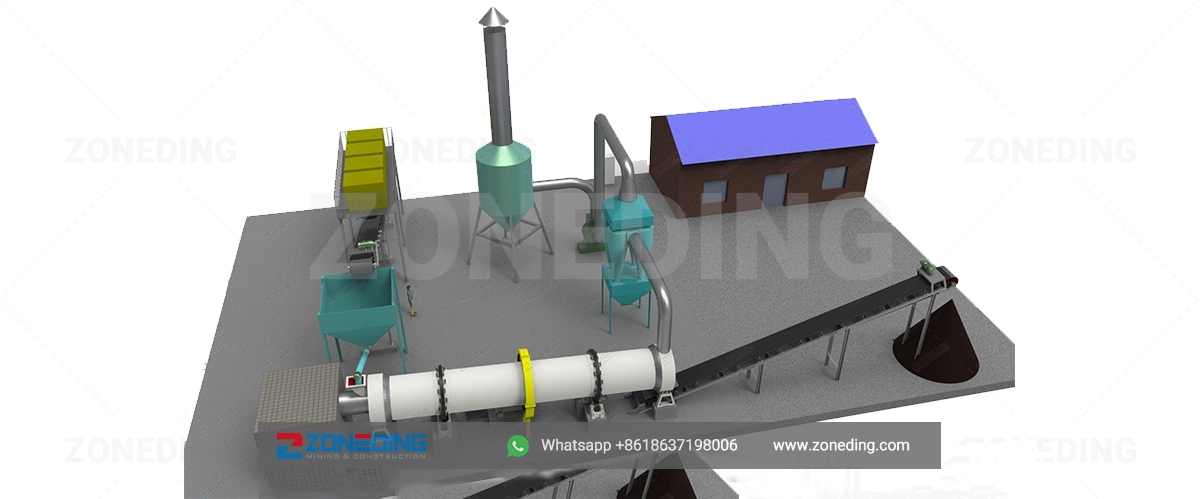

A professional lignite drying system is a carefully staged, closed-loop process focused on safety and efficiency.

A lignite dryer is a highly specialized piece of industrial equipment, almost always a modified rotary dryer for lignite. It is fundamentally different from a standard dryer because it is engineered as a sealed, oxygen-starved pyrolysis environment. The primary goal is to heat the lignite to drive off water without providing the oxygen needed for it to burn. It is a chemical reactor first and a dryer second. The entire design philosophy revolves around mitigating the extreme fire and explosion risk associated with dried lignite dust.

A lignite dryer is a strategic asset for any industry that has access to cheap lignite deposits and a need for low-cost, high-volume energy. The primary industries that invest in lignite drying systems are:

Investing in a professional lignite dryer offers transformative benefits.

A safe and effective lignite dryer is a system of interconnected, purpose-built components.

Lignite Dryer adopts the new technology of drying after crushing, which realizes the industrialization, automation and continuous production. When the lignite dryer machine works, wet lignite is fed into the crushing equipment firstly. Then low-temperature four-stage drying process is introduced and dries the wet lignite to the humidity of 13% or below.

Working Principle of Lignite Dryer

The process is a masterclass in controlled pyrolysis.

First Level: 400 ℃, high temperature removes most of the moisture and make sure the lignite not change chemically;

Second Level: 300 ℃, strong wind produced works in high efficiency to ensure that the lignite is not coking;

Third Level: 120-210℃, with the crushing function of the cleaning devices inside the cylinder, wet lignite flows in the cylinder and is dried;

Fourth Level: 60-80℃, the removal of water depends on low-temperature current produced by the induced draft system.

Therefore, lignite dryer can take full advantage of the coal resources and reduce the emission concentration, so as to achieve energy-saving emission reduction and environmental protection objectives.

At ZONEDING, our lignite dryer design is built around the “safety first” principle, incorporating decades of experience with dangerous materials.

The brown coal rotary dryer price is a significant investment, typically ranging from $300,000 to over $3,000,000. The price is dictated by its water evaporation capacity and the extensive, non-negotiable safety and material requirements. The need for an inert gas generation system, extensive safety monitoring (CO, O2, temperature), explosion-proof motors and sensors, and stainless steel components for corrosion resistance all contribute to the higher cost compared to a simple mineral dryer. This is not just a machine; it’s a complete processing plant where safety engineering constitutes a major part of the value and cost.

Choosing a lignite dryer is one of the most serious safety decisions you can make.

Maintaining a lignite dryer is a task centered on safety and planned replacement, not preventing wear. The machine is designed as a consumable workhorse. Your top priorities should be:

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Can ZONEDING Company Provide the Customized services?

Yes, absolutely. Every lignite source is different. We custom-engineer every lignite drying system based on your specific material analysis, required capacity, and site conditions. We can design everything from the dryer itself to a complete, self-sufficient plant with its own fuel system.

How Do You Control Final Moisture for Maximum Calorific Value?

Final moisture is precisely controlled by a feedback loop. Temperature sensors at the dryer outlet measure the product temperature, which is directly related to its moisture content. The PLC control system then automatically adjusts the temperature of the inert gas and the feed rate of the wet lignite to consistently hit the target moisture, typically 10-15%.

What Fuel Sources Can Economically Power the Dryer Itself?

While the dryer can be powered by natural gas, diesel, or other conventional fuels, the most economical solution by far is to use the product itself. We design systems with a gasifier or specialized furnace that uses a small portion of the final upgraded lignite to generate the hot, inert flue gas needed for the process.

What Factors Determine the Final Lignite Dryer Investment Cost?

The main factors are: 1) Water evaporation rate (tons/hour), which dictates the physical size of the machine. 2) The scope of supply (dryer only vs. a complete plant with fuel system, conveyors, and storage). 3) The level of automation required. 4) The specific materials of construction needed (e.g., grade of stainless steel).

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

loading…

已经是到最后一篇内容了!