Hydraulic Cone Crusher: How it Works, Why it’s Your Crushing Solution

3941Understand hydraulic cone crushers' working principle and key features: hydraulic adjustment, overload protection, and high efficiency in mineral processing.

View detailsSearch the whole station Crushing Equipment

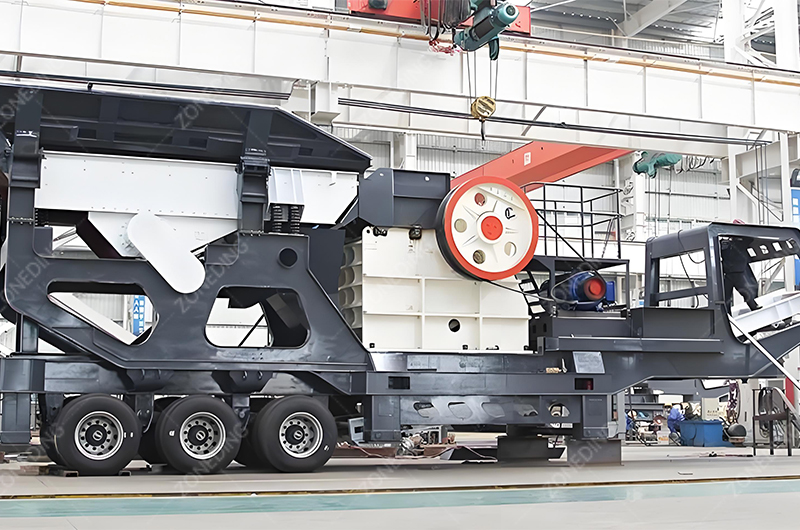

You are asking for the price of a mobile stone crusher, but you feel trapped. You see wildly different numbers online and don’t know why. You need a real budget number, but you are afraid of buying the wrong machine.

A mobile stone crusher can cost from $100,000 for a small, basic model to over $1,000,000 for a large, high-production plant. The final price is not arbitrary. It is directly determined by seven key decisions about your specific project needs.

I am going to break down the seven factors that actually build the final price tag. As a manufacturer, we see customers make costly mistakes by not understanding these points. By the end of this article, you will be able to define your needs and understand what a realistic budget for your project should be.

You are crushing rock, but what kind of rock and for what purpose? This is the first and most important question. The type of crusher is the core of the machine and the biggest factor in its base price.

Choose a mobile jaw crusher for hard rock primary crushing. Choose a mobile cone crusher for secondary crushing of hard rock. Choose a mobile impact crusher for recycling concrete and asphalt or for softer stone.

Choosing the wrong type is a disaster. It leads to extremely high wear costs, poor product shape, or a machine that simply cannot crush your material.

Are you running a small contracting business or supplying a major highway project? Your required production capacity directly determines the physical size of the machine and its price.

A 100 TPH machine is a completely different class of equipment from a 400 TPH machine. The price increases significantly with size because every component—the crusher inlet, the engine, the chassis, the conveyors—must be bigger and stronger.

Higher TPH is not just a bigger number; it’s a step-change in engineering and cost.

| Capacity (TPH) | Machine Class | Price Impact | Common Use |

|---|---|---|---|

| 50-150 | Compact | Lowest | Small demo sites, landscape supply, tight spaces |

| 150-400 | Production | Medium-High | Quarries, medium to large contractors, road building |

| 400-800+ | High-Capacity | Highest | Major infrastructure projects, large-scale mining |

A 300 TPH jaw crusher needs a much larger and more powerful diesel engine than a 100 TPH model. This engine alone can account for a huge jump in price. The steel frame has to be thicker and heavier. The discharge conveyor has to be wider and longer. Each increase in capacity has a compounding effect on the overall cost.

How will you move your machine around the job site? The choice between a tracked mobile crusher (crawler) and a wheeled crusher (tyre-mounted) has a major impact on both price and operational flexibility.

Tracked crushers are more expensive but offer superior on-site mobility and faster setup. Wheeled crushers have a lower initial cost and are easier for long-distance road transport, but require more site preparation and have limited mobility on rough terrain.

Your site conditions and business model will determine the right choice.

The price you see advertised is often for a base machine. The final price you pay will include the essential options needed to make your specific product.

Options like a pre-screen, magnetic separator, or a closed-circuit return conveyor are not luxuries; they are essential tools for many applications. Each of these systems adds to the total cost of the mobile crushing station.

It is critical to budget for these from the start.

You can find two mobile jaw crushers with the same stated capacity, where one costs three times more than the other. This price difference is not random; it reflects differences in engineering, components, and support.

Premium brands (like Kleemann, Metso) have higher prices due to their investment in R&D, use of high-end components (e.g., CAT/Scania engines), advanced automation, and global service networks. Value-focused manufacturers like us (ZONEDING) offer a lower price by selling factory-direct and using robust, proven designs without the overhead.

Understanding the brand tiers helps you align your budget with your needs.

How you power your crusher affects both the initial purchase price and your daily operating costs. This is an increasingly important factor.

Direct diesel-hydraulic drive is the traditional, simplest, and often cheapest option to buy. Diesel-electric or fully electric options have a higher initial price but can dramatically lower your long-term fuel and maintenance costs.

Your choice depends on your long-term business plan.

The real cost of owning a mobile stone crusher is not the price you pay upfront. It is the Total Cost of Ownership (TCO) over its entire life. A cheap machine can be the most expensive one to own.

You must calculate your cost per ton to produce. This means factoring in daily fuel consumption and the cost and lifespan of wear parts (jaw plates, blow bars, mantles). A cheap machine that burns more fuel and needs new wear parts every month will destroy your profit.

Before you buy, ask the manufacturer these questions:

A manufacturer who can give you clear, confident answers to these questions is one you can trust.

The price of a mobile stone crusher is a direct result of the choices you make. Instead of asking for a price, define your needs first: type, capacity, mobility, options, and power source. Then, you can find the right partner to build the right machine for you.

Understand hydraulic cone crushers' working principle and key features: hydraulic adjustment, overload protection, and high efficiency in mineral processing.

View detailsThe selection between Direct Flotation and Reverse Flotation constitutes a fundamental engineering decision in the design of mineral processing circuits. This choice is not merely based on mineral hydrophobicity but involves a complex analysis of...

View detailsDesign a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsHow to select the best barite processing equipment for operations? Learn about crushing, grinding, and beneficiation technologies to optimize efficiency yield.

View details