From Mine to Mill: Extraction & Ore Dressing Equipment

3553What's the difference? Extraction equipment handles raw mining. Ore dressing (beneficiation) equipment refines the ore. Discover their unique functions.

View detailsSearch the whole station Crushing Equipment

Oxidized gold deposits are often considered geologically simpler to process. However, selecting an inappropriate extraction method can severely impact a project’s economic viability, turning a potential asset into a liability.

The principal hydrometallurgical methods for oxidized gold ore extraction are Heap Leaching and Carbon-in-Leach (CIL). Heap Leaching is applied to large-tonnage, low-grade ores, while CIL is reserved for higher-grade or metallurgically complex ores. The optimal process is dictated by ore-specific mineralogical and geotechnical characteristics.

As a manufacturer that designs and supplies equipment for gold ore processing projects, we at ZONEDING understand that project success hinges on technical details. While academic principles outline the options, practical experience is essential for selecting the correct flowsheet. This article will detail the critical factors for making an informed decision.

Engineers and geologists often classify oxidized ore as ‘free-milling,’ a term that implies simpler processing. This classification, however, requires careful definition to avoid misinterpreting the metallurgical challenges involved.

Oxidized ores are termed ‘easier’ because the gold particles are liberated and chemically accessible. They can be leached directly with a cyanide solution, bypassing the costly and energy-intensive pre-treatment (e.g., roasting, pressure oxidation) required for refractory sulfide ores where gold is encapsulated.

The term ‘oxidized’ describes a zone of supergene weathering where atmospheric oxygen and water have altered the primary ore mineralogy. Sulfide minerals, such as pyrite, which commonly host or encapsulate gold, are decomposed into oxides and hydroxides (e.g., goethite, hematite). In refractory sulfide ores, this gold is physically locked and chemically inaccessible. Extracting it requires destroying the sulfide matrix. In oxidized ores, this natural decomposition has already occurred. The gold particles, though often microscopic, are physically liberated and available for direct contact with a lixiviant like cyanide. This geological pre-treatment significantly simplifies the metallurgical flowsheet for gold ore processing, reducing complexity and cost compared to refractory ore treatment.

With the gold being chemically accessible, the next step is determining the most effective extraction method. For commercial-scale oxidized gold ore extraction, the options condense to a few primary processes.

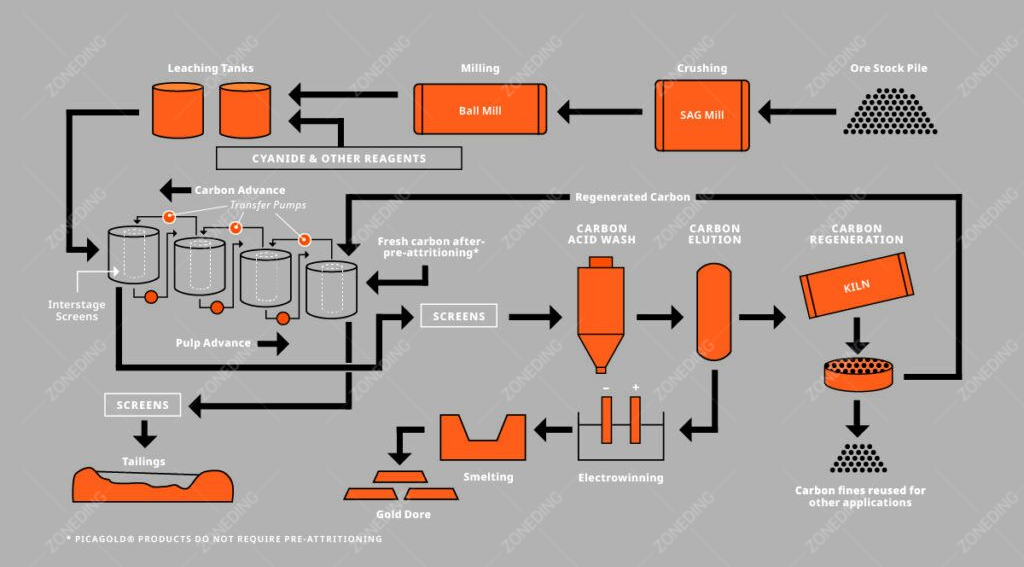

The primary methods are Heap Leaching, Carbon-in-Leach (CIL), and Carbon-in-Pulp (CIP). Gravity concentration is frequently integrated as a pre-concentration step to recover coarse, free gold. These processes can be implemented individually or in combination to optimize recovery.

Here is a technical overview of the primary methods, based on our experience in equipment supply and process design.

This is a primary method for large, low-grade gold ore deposits (typically 0.5 – 1.5 g/t). The process involves crushing the ore, stacking it on an impermeable liner, and irrigating the stack with a dilute cyanide solution. The solution percolates through the heap, dissolving the gold, and the gold-bearing solution is collected for recovery.

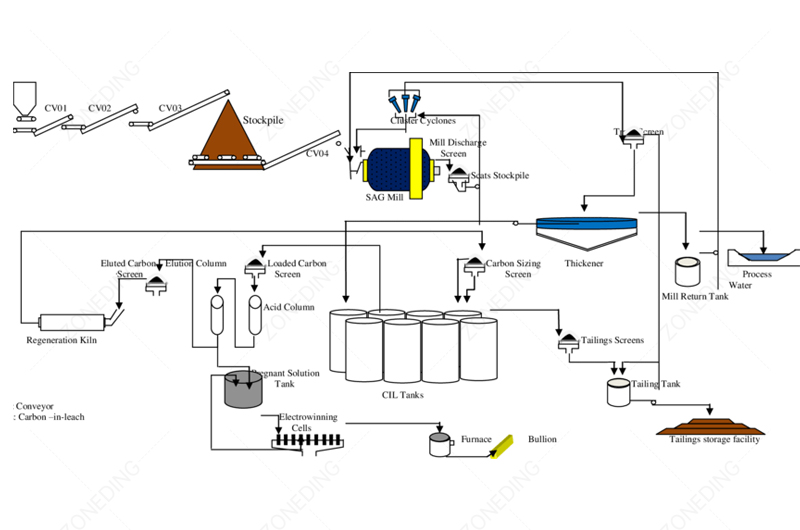

For higher-grade or metallurgically complex ores, CIL/CIP is employed. In these processes, the ore is ground to a fine slurry. Leaching and adsorption occur in a series of large, agitated tanks where activated carbon is used to recover the dissolved gold from the slurry.

This method leverages the high specific gravity of gold to separate it from lighter gangue minerals. While rarely a complete solution, integrating a gravity circuit with equipment like a Centrifugal Concentrator can recover a significant portion (20-40%) of free gold at a low cost before the leaching stage.

A process flowsheet is defined by its required equipment. The capital cost and operational complexity of a project are directly tied to the machinery that must be procured, installed, and maintained.

A Heap Leach circuit primarily consists of crushers, conveying systems, and potentially an agglomeration drum. A CIL plant is significantly more capital-intensive, requiring a complete grinding circuit with ball mills and a train of large, agitated leaching tanks.

The equipment scope defines the project’s capital cost and operational complexity. As a manufacturer of this full range of minerals processing machines, we design circuits based on these distinct equipment requirements. The following table provides a typical equipment breakdown for each process:

| Process | Key Equipment Required | Primary Function |

|---|---|---|

| Heap Leaching | Jaw Crusher, Cone Crusher | Ore size reduction to a target crush size. |

| Conveyors & Stacker | Material transport and placement on the leach pad. | |

| Agglomeration Drum | Pelletizing fine particles with a binder (e.g., cement). | |

| Irrigation System & Pumps | Application and circulation of the lixiviant solution. | |

| CIL / CIP Plant | Full Crushing Plant | Multi-stage crushing to prepare ore for grinding. |

| Ball Mill & Cyclones | (High-Cost Item) Liberation of gold through fine grinding. | |

| Leaching/Agitation Tanks | (High-Cost Item) Vessels for leaching and adsorption. | |

| Thickeners, Pumps | Slurry density control and water management. | |

| Carbon Screens | Separation of loaded carbon from the slurry. |

This is the most critical technical decision in project development. The selection must be based on empirical data from the ore itself to ensure a positive gold recovery rate and economic outcome.

The decision is driven by four key factors: gold grade, clay content, gold particle size, and the presence of ‘preg-robbing’ carbonaceous material. These factors, determined by metallurgical testing, dictate the technical and economic viability of each process.

Based on our extensive experience, the process selection is a technical trade-off informed by a detailed orebody analysis.

The project’s financial structure depends on the balance between initial investment and long-term returns. The capital cost differential between these two methods is substantial and is a key determinant of project feasibility.

The capital expenditure (CAPEX) for a CIL plant is substantially higher than for a heap leach operation. The primary cost drivers are the grinding circuit, specifically the ball mills, and the series of agitated tanks, which are not required for heap leaching.

An analysis of major cost centers clarifies the difference.

Among the gangue minerals present in an ore, clays are particularly deleterious to hydrometallurgical processes. Underestimating their impact is a common cause of operational failure in oxidized gold ore extraction.

High clay content severely compromises heap leach permeability by blocking solution pathways. In a CIL circuit, it increases slurry viscosity, leading to higher power consumption, accelerated equipment wear, and potential mass transfer limitations that inhibit gold adsorption.

The specific detrimental effects of clay differ by process.

Clay particles, due to their fine size and plate-like structure, migrate with the solution flow and block the interstitial voids between larger rock fragments. This loss of permeability results in solution “channeling” and the creation of large unsaturated zones within the heap, preventing the lixiviant from contacting the gold in those regions.

In a milled circuit, high-clay ore generates high-viscosity slurries. This has several deleterious effects:

Process selection for a multi-million dollar investment must not be based on assumptions. The final decision for your gold ore processing flowsheet must be validated by scientific evidence derived from your specific ore.

A definitive process selection requires comprehensive metallurgical ore amenability testing. This is a multi-stage investigation designed to simulate process options at lab and pilot scales, generating quantitative data on recovery, reagent consumption, and identified processing risks.

A structured test program is the most effective method for de-risking a project. At ZONEDING, we maintain that equipment selection is a direct outcome of these test results. A typical program includes:

Selecting the optimal oxidized gold ore extraction method is a data-driven engineering decision. The ore’s specific mineralogical characteristics, not generalized assumptions, determine whether heap leaching or CIL represents the most profitable process.

What's the difference? Extraction equipment handles raw mining. Ore dressing (beneficiation) equipment refines the ore. Discover their unique functions.

View detailsEquipment choice impacts everything. This guide breaks down the 5 essential factors for selecting lithium ore processing equipment for optimal recovery rates.

View detailsExplore the complete process of converting spodumene ore into high-grade lithium concentrate. Covers all vital steps, from crushing to final beneficiation.

View detailsChoosing the right crusher is key. We compare cone, VSI, and impact crushers for producing consistent, high-quality fines for any project.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy