Efficient Iron Ore Processing: A Five-Step Guide to Success

3548The perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsSearch the whole station Crushing Equipment

Building an activated charcoal plant is a significant industrial undertaking that requires careful planning and the right equipment. As manufacturers of the core machinery involved, we want to provide a clear, step-by-step guide for potential investors. The process is more than just heating a raw material; it involves precise material preparation, a controlled carbonization stage, and a highly technical activation stage. A successful activated charcoal production line depends on selecting the correct equipment for each of these critical steps. This guide will walk you through the essential machinery you’ll need, from raw material intake to the final, high-value product.

The first stage in any activated charcoal plant is raw material preparation. This step is non-negotiable for achieving a high-quality and consistent final product. Uniformity is the primary goal. Raw materials like coconut shells, wood logs, or coal arrive in various sizes and moisture levels. If you feed uneven material into the carbonization furnace, it will heat inconsistently. Smaller pieces will turn to ash while larger pieces remain under-processed, drastically reducing your yield and quality.

To prevent this, you need a dedicated preparation circuit. This typically includes:

Carbonization, also known as pyrolysis, is the process of heating the prepared raw material in a low-oxygen environment. The goal is not to burn the material, but to thermally decompose it. This process removes water, volatile organic compounds, and other elements, leaving behind a fixed-carbon mass called “char.” This char is the precursor to activated charcoal.

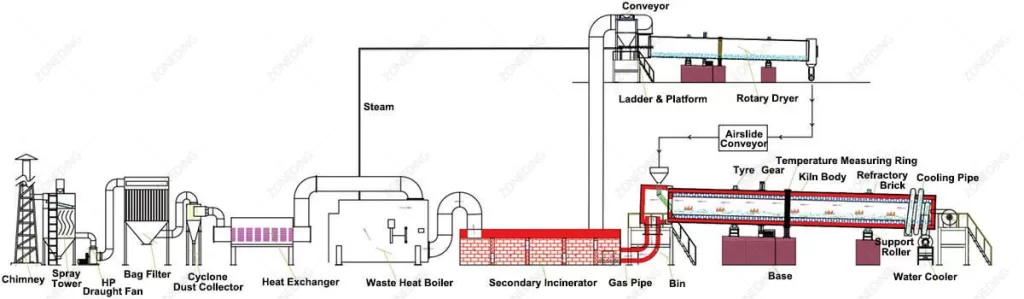

The core piece of activated charcoal equipment for this stage is the carbonization furnace. For continuous, industrial-scale production, a Rotary Kiln is the standard choice. The kiln rotates slowly, tumbling the material to ensure every particle is heated evenly to temperatures between 600-900°C. A critical control point is maintaining a low-oxygen atmosphere to prevent the char from combusting into ash. Modern plants capture the flammable syngas released during this process and use it as a secondary fuel source to heat the kiln, significantly improving energy efficiency.

This is the most critical, value-adding step in the entire process. Activation is what transforms low-value char into high-performance activated charcoal. The process dramatically increases the material’s internal surface area by creating a vast network of microscopic pores.

This is achieved in an activation furnace, which is another, more robust rotary kiln capable of withstanding even higher temperatures (900-1200°C). Inside this kiln, the char is heated to the target temperature, and a controlled amount of an activating agent—typically superheated steam or carbon dioxide—is injected. The steam reacts with the carbon surface in a process of controlled gasification. It etches and erodes the internal pore walls, developing an intricate, interconnected network of micropores. It is this massive increase in specific surface area, often reaching 500-3,000 m²/gram, that gives activated charcoal its powerful ability to adsorb molecules from liquids and gases.

| Feature | Carbonization | Activation | Your Key Takeaway |

|---|---|---|---|

| Operating Temperature | 600-900°C | 900-1200°C | The activation kiln requires superior refractory materials and construction to handle extreme heat. |

| Process Control | Control oxygen levels | Precise control of temp, steam flow, and residence time | Activation is a technical process. The control system is vital for final product quality. |

| Material Stress | Moderate thermal stress | High thermal and chemical stress | The activation furnace is a more specialized, higher-cost piece of equipment. |

| Value Added | Creates precursor char | Creates the final high-value product | Your main investment in quality should be focused on the activation stage equipment. |

A complete, industrial-scale activated charcoal production line is a multi-stage system. While configurations vary based on raw material and capacity, a typical line includes:

The cost to build an activated charcoal plant varies enormously. A very small, basic batch-style system might be possible for under $100,000 USD. However, a proper, continuous industrial activated charcoal production line represents a significant capital investment.

A small-to-medium scale plant with a capacity of a few thousand tons per year could range from $500,000 to over $2 million USD. The final cost depends on:

Your choice of raw material fundamentally defines your final product and, therefore, your equipment needs.

Owning the right activated charcoal equipment is only part of the equation. Long-term success depends on several other critical business and operational factors:

Consistent Raw Material Supply: Securing a stable, long-term supply of your chosen feedstock at a predictable price is paramount.

Q1: What is the difference between physical (steam) and chemical activation?

A: Steam activation (physical) is a two-step process (carbonization, then activation) that produces a very pure product but is highly energy-intensive. Chemical activation uses an agent like phosphoric acid in a single, lower-temperature step but requires extensive washing of the final product and creates a wastewater treatment challenge.

Q2: Can I use a single kiln for both carbonization and activation?

A: While technically possible in some batch systems, it is highly inefficient for industrial production. Continuous plants use two separate, optimized kilns to maintain a steady workflow and allow for precise control over each distinct process.

Q3: How important is the quality control lab?

A: It is absolutely critical. You cannot sell your product without verifying its quality. An in-house lab to test key metrics like Iodine Number (for microporosity), Molasses Number (for mesoporosity), hardness, and ash content is essential for process control and to provide certificates of analysis to your customers.

Q4:What is the typical return on investment (ROI) for an activated charcoal plant?

A: The ROI depends entirely on your capital costs, operating expenses (especially raw material and energy), and the market price for your specific grade of activated carbon. High-spec carbons for applications like gold recovery command a premium price and can offer a strong ROI, but require a higher initial investment in quality equipment.

Building an activated charcoal plant is a complex but potentially very profitable venture. Success hinges on a clear strategy and investing in the right equipment for each stage of the activated charcoal production line.

The key stages are raw material preparation, carbonization, and the value-adding activation process. The activation stage, requiring a high-temperature Rotary Kiln with precise controls, is the most technically demanding and is central to producing a high-quality product.

As you plan your project, focus not just on the machinery, but on your raw material strategy, energy costs, and target market.

The perfect solution for gold mining. Our portable hard rock crushers are engineered to process gold-bearing ore efficiently.

View detailsGravity separation remains the primary method for gold recovery in both artisanal and industrial mining operations. It functions on the principle of Specific Gravity (SG), utilizing the density difference between gold (SG approx. 19.3) and typica...

View detailsBuild an efficient quartz sand plant. See our advanced equipment for high-quality production & get a precise quotation tailored to your operational needs.

View detailsLearn various methods for separating antimony ore, including gravity separation, flotation, magnetic separation. Improve your antimony recovery process today!

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy