What are the Most Effective Methods for Kaolin Iron Removal and Purification?

3535Our complete guide walks you through the process of iron removal from kaolin clay. Boost whiteness and quality for industrial applications like ceramics.

View detailsSearch the whole station Crushing Equipment

This article discusses building a top-tier limestone sand making production line. The focus is on making manufactured sand. A system should provide high-quality sand. It also needs to generate good profits. Many operations concentrate only on running machines. But real success comes from understanding the details. This involves knowing limestone’s unique characteristics, meeting final product demands, and making small, smart adjustments that boost performance. This guide shows how to achieve these goals. It helps ensure long-term success.

Limestone is a popular and cost-effective raw material for manufactured sand, producing high-quality aggregate for roads and concrete due to its abundance and ease of mining. ZONEDING’s expertise ensures efficient processing.

Its cubical shape ensures superior concrete strength and durability, requiring less cement and water. As natural sand sources deplete, manufactured limestone sand offers a reliable, consistent alternative. Advanced crushing allows precise control over size and shape, yielding a superior product that meets strict building standards for concrete, asphalt, railway, and highway applications.

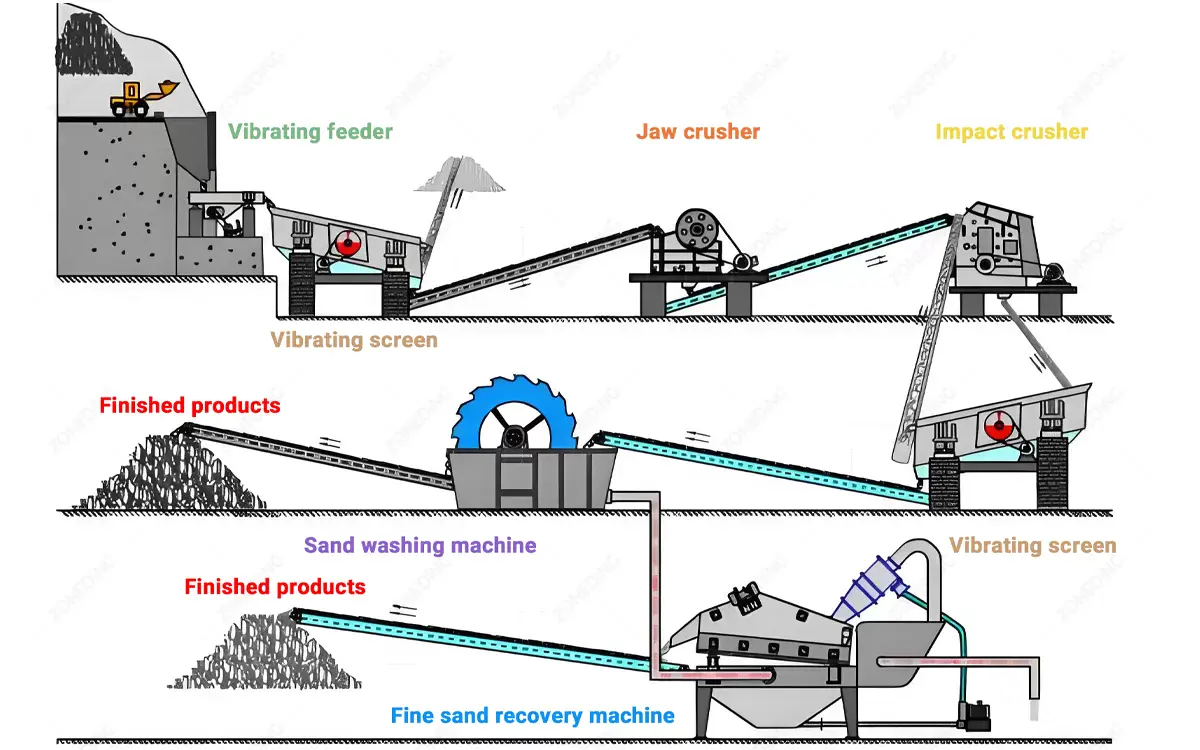

A successful Sand Making Production Line, from raw limestone to high-quality sand, optimizes each step for efficient material flow and maximum output. The process begins with raw limestone fed into primary, then secondary and tertiary crushing. The “Pre-Shape Imperative” is crucial: particle shape before the VSI matters significantly. An optimized cone crusher delivering cubical feed allows the VSI to efficiently shape sand, improving quality and reducing wear. Post-crushing, screening separates sizes, after which a VSI (Vertical Shaft Impact) crusher shapes particles into high-quality sand. Conveyors link stages and dust collectors manage air quality, all focused on achieving optimal size, shape, and low operating costs.

Choosing the right core equipment is key for a successful limestone sand making production line. This means picking crushers, sand makers, and screens that match limestone’s unique traits. It ensures high output and top-quality sand. Making the right choices here can save significant money and time later. Many factors go into these decisions.

Planning a limestone sand making production line layout is critical. A smart layout maximizes output while lowering energy use and running costs. Such a layout isn’t merely about machine placement; rather, its essence lies in creating a smooth, logical material flow that minimizes unnecessary transport and stops.

Controlling the quality of manufactured sand is very important. It needs to meet strict construction standards. This means managing particle shape, gradation, and powder content. High-quality sand leads to better concrete and asphalt. It gives a competitive edge. Achieving this quality requires careful choices in equipment and operation.

| Quality Parameter | Equipment/Method | Direct Benefit |

|---|---|---|

| Particle Shape | VSI Sand Maker (Closed Rotor) | Higher strength concrete, reduced cement use |

| Gradation | Multi-deck Vibrating Screens | Meets exact project specifications |

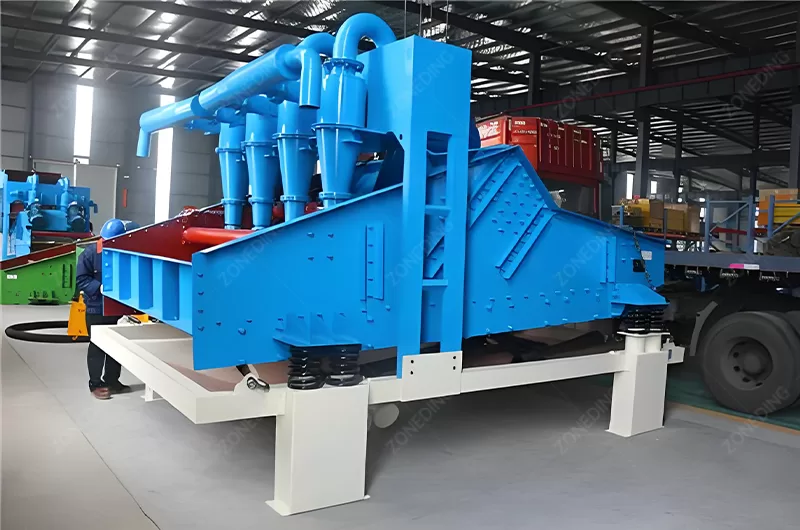

| Fines Content | Sand Washing Machine, Hydrocyclone | Optimized concrete mix, prevents segregation |

| Cleanliness | Sand Washing Machine, Attrition | Durable structures, higher market value |

Meeting environmental rules is crucial for sustainable, compliant limestone sand production, necessitating proactive planning due to tightening regulations.

While wet washing is often chosen, a fully dry sand making process, especially in dry areas, offers significant cost and environmental benefits if feed moisture is properly managed. The “Moisture Threshold” is key: limestone clumps or blinds screens above 3-5% moisture. Below this, dry air classification and screening work efficiently. If raw material consistently exceeds its critical moisture content, a dedicated pre-sand making drying stage may be more economical than full wet washing, drastically reducing water usage, dewatering energy, and waste.

Beyond just equipment, operational management “secrets” significantly boost profit. For limestone deposits with significant clay or impurities, “Attrition Scrubbing” is a game-changer. A VSI alone cannot yield premium sand from dirty material. Integrating a log washer or high-intensity attrition cell removes adhered clay and polishes aggregate surfaces, greatly improving cleanliness for high-quality concrete. This targeted processing transforms product from “general purpose” to “premium manufactured sand,” enabling higher market prices and expanded sales.

| Operational Secret | Impact on Profitability | Practical Result |

|---|---|---|

| Fines Management | Turns waste into revenue, reduces disposal costs | Additional income stream, improved sustainability |

| Attrition Scrubbing | Upgrades product to premium status, higher selling price | Access to high-value markets, stronger reputation |

| VSI Component Choice | Lower wear costs per ton, better cubicity | Reduced operating expenses, superior product output |

| Performance Audits | Identifies savings and efficiency gains | Continuous improvement, higher profit margins |

The limestone sand making production line industry continues to evolve. New technologies and trends focus on increased efficiency, sustainability, and automation. These developments help operations stay competitive. They also meet rising demands for high-quality construction materials. Staying informed about these trends is crucial for long-term success.

Innovations in equipment design, process control, and material science drive these advancements. Digitalization plays a growing role. Smart factories use data analytics to optimize performance in real time. Advanced wear materials extend equipment life. This reduces maintenance downtime. Environmental concerns also push for greener solutions. These include more efficient water recycling and dust control. These trends shape the future of limestone sand production. They offer significant opportunities for improvement and profitability.

The global demand for manufactured sand is projected to grow steadily. This is driven by rapid urbanization and infrastructure development. Depletion of natural sand resources further accelerates this trend. Operations adopting efficient, sustainable, and technologically advanced production lines are best positioned to capture market share. They also ensure long-term profitability. This shift towards manufactured sand represents a significant market opportunity.

Question 1: What is the ideal moisture content for limestone in a dry sand making process?

The ideal moisture content for limestone in a dry sand making process is generally below 3-5%. Exceeding this causes fines to clump, blinding screens and hindering dry classification. Knowing the specific critical moisture content is crucial.

Question 2: How often should wear parts in a VSI sand maker be checked?

Visual inspection of VSI wear parts (rotor tips, wear plates, anvils) should be daily, with detailed checks weekly, especially for abrasive limestone. Regular checks predict replacements, prevent sudden failures, and maximize equipment lifespan.

Question 3: Can limestone fines be used in concrete without issues?

Yes, limestone fines can be used in concrete, but must meet specific quality standards. Particle size and cleanliness are critical; excessive or impure fines can reduce strength and increase water demand. Proper classification and testing are essential for suitability as a supplementary cementitious material.

Question 4: What is the main advantage of a closed rotor VSI over an open rotor for limestone?

The main advantage of a closed rotor VSI for limestone is superior particle shaping, forcing more rock-on-rock crushing for a higher percentage of cubical particles. This is ideal for high-quality manufactured sand. Though rotor shoe wear costs may be higher, improved product quality often justifies it.

Building a high-quality, profitable limestone sand making production line demands careful planning and smart operation. Beyond just machinery, it requires understanding limestone’s unique traits and optimizing every stage: initial crushing, VSI shaping, and fines management. Implementing advanced screening and strategic surge piles is vital to reduce costs and boost output. Precise equipment choices and environmental compliance are crucial for sustainable, long-term success.

ZONEDING recommends a holistic approach, combining top-tier Mining Machinery with expert operational strategies. This ensures high-quality manufactured sand production and maximizes investment return. Partnering with ZONEDING helps design optimal systems, meeting tough standards and delivering lasting profitability.

ZONEDING MACHINE is a leading Chinese mineral processing equipment manufacturer. It specializes in B2B solutions. ZONEDING has provided reliable equipment since 2004. Our factory covers 8,000 square meters. It produces over 500 units annually. Our product range is comprehensive. It covers crushing, grinding, beneficiation, screening, and drying. ZONEDING offers full-service support. This includes design, manufacturing, installation, training, and after-sales service. Our products export to over 120 countries. ZONEDING commits to delivering high-quality, customized, and efficient solutions. These help operations achieve their goals.

Contact ZONEDING today to discuss your limestone sand making project.

Our complete guide walks you through the process of iron removal from kaolin clay. Boost whiteness and quality for industrial applications like ceramics.

View detailsExplore secondary impact crushers for efficient material reduction. They produce cubical, well-shaped aggregate, ideal for construction, road building.

View detailsOptimize mineral processing! Compare spiral classifiers vs. hydrocyclones. Learn 5 differences to select ideal equipment for efficiency & beneficiation.

View detailsProcessing tin ore (Cassiterite) might appear straightforward due to its significant weight. However, decades of industry experience demonstrate that high specific gravity is deceptive. Cassiterite is fragile and shatters easily. Without a precis...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy