How to Choose Optimal Barite Processing Equipment?

3794How to select the best barite processing equipment for operations? Learn about crushing, grinding, and beneficiation technologies to optimize efficiency yield.

View detailsSearch the whole station Crushing Equipment

A Secondary Impact Crusher represents a vital component in modern aggregate production. This machine follows a primary crusher in a Crushing Production Line, performing the essential function of further size reduction and shaping of materials. The equipment’s operational principles focus on material impact rather than compression. This approach creates distinct advantages for producing high-quality aggregate.

This article provides a comprehensive overview of the Secondary Impact Crusher, its working mechanisms, benefits in generating cubical aggregate, material suitability, and strategic considerations for model selection. It includes insights for effective operation and cost management.

A Secondary Impact Crusher is a type of crushing equipment designed for the second stage of material size reduction. It typically receives feed material that a Jaw Crusher or another primary crushing unit has already processed. The purpose of this secondary stage is to reduce the material further. It also improves the shape of the aggregate. This machine is pivotal for achieving the desired product specifications in aggregate production operations.

| Crushing Stage | Key Equipment | Typical Feed Size (Approx.) | Typical Output Size (Approx.) | Material Fineness Classification | Output Particle Shape Characteristics |

|---|---|---|---|---|---|

| Primary Crushing | Jaw Crusher | Below 1000mm | 100-300mm | Coarse Crushing | High reduction ratio, but poor particle shape; high content of flaky and elongated particles. |

| Secondary Crushing | Impact Crusher | 100-300mm | 0-80mm (0-50mm/0-40mm) | Medium Crushing | Excellent cubical particle shape, low flakiness/elongation; suitable for medium-hard materials. |

| Tertiary Crushing | VSI Sand Making Machine (Vertical Shaft Impact Crusher) | 0-80mm (0-40mm) | 0-5mm (0-10mm) | Fine Crushing / Sand Making | Extremely good cubical particle shape, excellent gradation; produces high-quality manufactured sand. |

The role of a Secondary Impact Crusher in a crushing production line is critical. It bridges the gap between the coarse output of primary crushing and the fine requirements of tertiary crushing or final product sizing. The equipment accepts medium-sized rock. It transforms this material into smaller, more uniform particles. These particles are suitable for construction and road-building applications. Proper integration of the impact crusher ensures a smooth flow of material and optimized overall plant efficiency. It handles a significant portion of the total size reduction work.

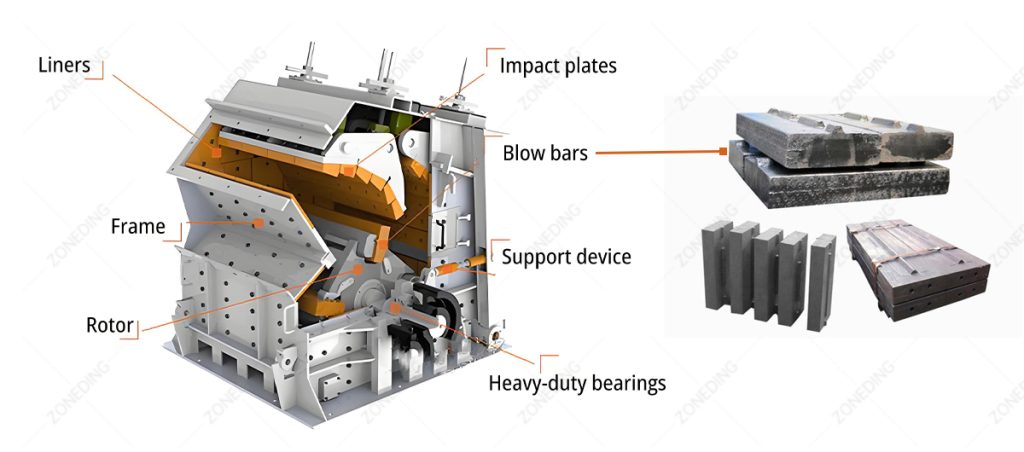

The impact crusher working principle relies on the rapid acceleration and collision of material. This process differs fundamentally from the compressive action of jaw or cone crushers. Material enters a chamber. Rapidly rotating blow bars mounted on a rotor strike it. The impact propels the material against stationary impact plates, also known as aprons, located in the crusher’s casing.

This action involves two primary crushing mechanisms:

The material continues to be impacted and broken until it is small enough to pass through the adjustable gap between the rotor and the impact plates. This creates a high Reduction Ratio. The continuous cycle of impact and attrition ensures efficient size reduction and shaping.

An Impact Crusher offers distinct advantages for producing high-quality aggregate, particularly cubical aggregate. The impact crushing mechanism naturally generates a more desirable particle shape compared to other crushing methods. When material is subjected to high-speed impact, it tends to break along its natural cleavage planes. This results in cubical, well-graded particles.

The cubical shape of aggregate particles is highly valued in the construction industry. Cubical aggregate packs more densely. It reduces the amount of binder material needed in concrete and asphalt mixes. This leads to stronger, more durable final products. Flaky or elongated particles create voids. These voids weaken the structural integrity. The consistent, blocky shape produced by an impact crusher contributes directly to the marketability and premium pricing of the aggregate. This machine’s ability to consistently produce Cubical Aggregate makes it a strategic investment for operations aiming to maximize product value. A high percentage of cubical material directly impacts the profitability of an Aggregate Production operation.

A Secondary Impact Crusher is best suited for processing specific types of materials. Its design excels with materials that are relatively soft to medium-hard and non-abrasive. These material characteristics allow the crusher to operate efficiently and economically.

Examples of highly suitable materials include:

Materials that are highly abrasive, such as granite, quartzite, or Basalt Crushing (which is very hard and abrasive), are generally not recommended for impact crushers, especially the HSI type. Processing these hard and abrasive materials leads to rapid wear of the Wear Parts, such as blow bars and impact plates. This results in frequent downtime and significantly increased operating costs. For abrasive rock, a Cone Crusher is often a more cost-effective choice for secondary crushing.

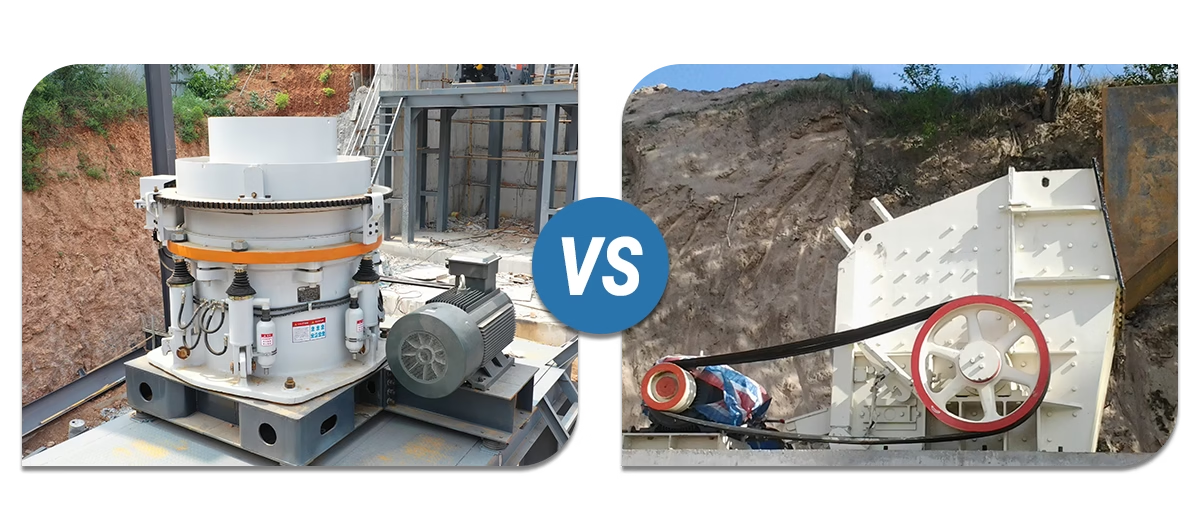

The choice between a Secondary Impact Crusher and a Cone Crusher for secondary crushing depends heavily on material properties and desired product characteristics. Each machine offers distinct advantages and disadvantages.

Advantages of an Impact Crusher:

Disadvantages of an Impact Crusher:

Advantages of a Cone Crusher:

Disadvantages of a Cone Crusher:

The decision is based on a trade-off between product quality (cubicity) and operating costs (wear) when considering material characteristics.

Impact Crusher Selection requires a thorough analysis of specific project parameters. An optimal choice ensures efficient operation and maximizes economic returns. Incorrect selection leads to reduced efficiency and increased operational expenditure.

The following criteria are essential for selection:

Detailed consultation with equipment specialists is recommended to match the correct Impact Crusher model to the specific demands of a project. This ensures a balanced and productive crushing circuit.

Managing Wear Parts consumption and routine Maintenance Cost is crucial for the profitable operation of a Secondary Impact Crusher. The impact mechanism inherently causes abrasion. Proactive strategies minimize downtime and extend component life.

Key management strategies include:

Effective management of these aspects transforms the Secondary Impact Crusher from a potential high-cost center into an efficient and profitable producer of High-quality Aggregate.

| Component | Wear Rate Factor | Management Strategy | Impact on Cost |

|---|---|---|---|

| Blow Bars | Material Abrasiveness, Rotor Speed | Material choice, Speed optimization, Rotation | High |

| Impact Plates | Material Abrasiveness, Feed Size | Gap adjustment, Material choice | Medium |

| Bearings | Lubrication, Load, Alignment | Regular lubrication, Condition monitoring | Low-Medium |

| Rotor | Tramp Metal, Unbalanced Load | Tramp metal removal, Feed control | Catastrophic |

Question 1: What is the primary difference between an HSI and a VSI crusher?

An HSI (Horizontal Shaft Impact) crusher uses blow bars on a horizontal rotor to impact material against fixed plates. It is designed for high reduction ratios and excellent cubical product shape in secondary crushing. A VSI (Vertical Shaft Impact) crusher uses a high-speed rotor to centrifugally accelerate material into the crushing chamber. The VSI often impacts other material (stone-on-stone). VSI crushers are typically used for tertiary crushing or sand-making. Fine product and superior shape are critical in these applications. They have higher wear costs for abrasive materials.

Question 2: How does rotor speed affect the crushing process in an impact crusher?

Rotor speed significantly influences product characteristics. Higher rotor speeds generally lead to finer product gradation, increased cubicity, and a higher reduction ratio. However, higher speeds also accelerate the wear of blow bars and impact plates. They increase power consumption. Optimized rotor speed aims for an efficient balance between product quality and wear part longevity. This leads to lower overall operating costs for the Impact Crusher.

Question 3: What materials should not be processed by an impact crusher?

Impact Crushers are not suitable for highly abrasive materials such as granite, basalt, or high-silica quartzites. Processing these materials results in extremely rapid wear of blow bars and impact plates. This leads to frequent downtime and high Maintenance Cost. Impact crushers are best suited for softer to medium-hard, non-abrasive materials like limestone, dolomite, and certain types of coal.

Question 4: Can a secondary impact crusher be used for primary crushing?

Generally, no. A Secondary Impact Crusher is designed for processing material that has already undergone primary reduction. Its feed opening is not typically large enough for raw run-of-mine material. Its internal components are not designed to withstand the immense impact forces of breaking very large, unprocessed rocks. Using it as a primary crusher leads to frequent blockages and severe damage.

The Secondary Impact Crusher is an indispensable machine for aggregate production, particularly where high-quality aggregate and cubical aggregate are desired. Its unique impact-based crushing mechanism offers superior product shaping capabilities. This machine transforms medium-sized raw materials into highly marketable finished products. Careful consideration of material properties is paramount for its economic application.

Effective Impact Crusher Selection balances production capacity, feed size, and product specifications. This includes careful consideration of material characteristics. Proactive management of Wear Parts and consistent maintenance practices are critical to controlling Maintenance Cost. When properly integrated and managed, an Impact Crusher significantly enhances the profitability and product quality of any crushing operation.

Since 2004, ZONEDING has manufactured high-performance mineral processing equipment. As a factory-direct supplier, the company provides a complete range of machinery, from single crushers to entire customized Stone Crushing Plants. Its team of 15 professional engineers ensures every machine is designed for maximum efficiency and a long service life. ZONEDING has delivered solutions to more than 120 countries.

Contact the company for a professional consultation and a competitive quote.

How to select the best barite processing equipment for operations? Learn about crushing, grinding, and beneficiation technologies to optimize efficiency yield.

View detailsIn the mining and aggregate sectors, a veteran axiom holds true: 'Crushers are not worn out; they are shaken out and repaired out.' While many operators fixate solely on throughput volume, neglecting the unique mechanical demands of each machine ...

View detailsTungsten is a strategic metal characterized by its extreme density and brittleness, often described in mineral processing as "heavy as iron but fragile as glass." The successful extraction of this metal depends entirely on correctly identifying t...

View detailsChoosing the right alluvial gold equipment is crucial. Compare trommel screens, jigs, and shaking tables to build an efficient processing line for max recovery.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy