What are effective ways to boost ball mill output/capacity?

3819Guide to improving ball mill output. Learn about optimizing grinding media, feed, speed, and liners to achieve maximum productivity and efficiency.

View detailsSearch the whole station Crushing Equipment

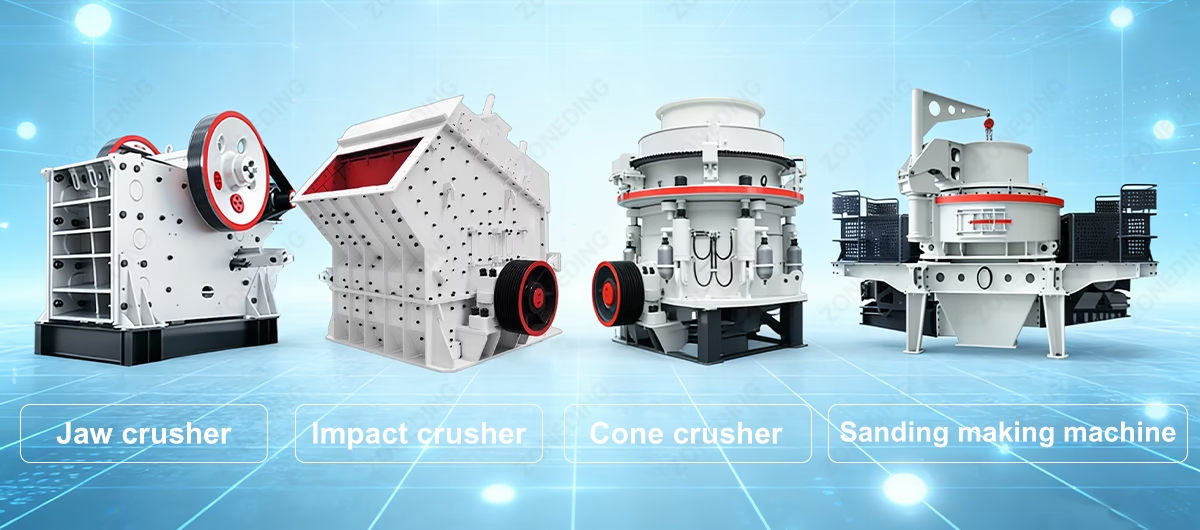

In the mining and aggregate sectors, a veteran axiom holds true: ‘Crushers are not worn out; they are shaken out and repaired out.’ While many operators fixate solely on throughput volume, neglecting the unique mechanical demands of each machine leads to premature failure. ZONEDING understands that disciplined maintenance is the key to extending equipment lifespan by 100% and reducing energy consumption by 20%. Leveraging extensive field expertise, ZONEDING presents essential maintenance protocols for Jaw, Cone, Impact, and VSI crushers, providing you with the actionable insights needed to eliminate costly downtime and maximize operational efficiency.

Maintenance is not a cost. It is an investment in profit. Many site managers wait for a machine to break. This is the “run-to-failure” method. This method is the most expensive way to operate. The cost of a breakdown is not just the repair bill. It includes the lost production revenue. It includes idle labor costs. It includes the high shipping fees for emergency parts.

Preventive maintenance follows a schedule. You change parts before they fail. Predictive maintenance uses data. You monitor the health of the machine in real-time. This changes the game. You fix issues only when necessary, but before catastrophe. This strategy increases equipment availability. It stabilizes your cash flow. It ensures safety for your workers. A well-maintained plant produces 20% more aggregate annually than a reactive plant.

The is a robust primary machine. However, two specific areas often cause major failures: the toggle seat and the feed size.

Toggle Seat Lubrication

Operators often view the toggle plate only as a safety device against overload. However, the toggle seat is a critical lubrication point. If the toggle seat runs dry, metal grinds against metal. This generates high-frequency vibrations. These vibrations transmit directly to the main frame. We have investigated many cracked frames. The cause is usually a dry toggle seat, not hard rock. You must grease the toggle seat daily. A well-lubricated toggle plate absorbs shock and protects the frame.

Feed Size and Nip Angle

A common error is feeding oversized rocks. The maximum particle size should be 85% of the feed opening width. If the rock is too large, the “Nip Angle” becomes too wide. The jaw plates cannot grip the material. The rock spins in the upper chamber. This causes “slippage” and rapid localized wear. It also stops production. If you see material popping back up (fly rock), your Closed Side Setting (CSS) is likely too wide. You should reduce the CSS or install jaw plates with a sharper tooth profile to improve the grip.

The Cone Crusher relies on “lamination crushing” principles. Efficiency depends on how you feed it.

The Necessity of Choke Feeding

90% of operators make a mistake here. They see a full hopper and slow down the feeder. This is incorrect. You must maintain a Choke Feed. You must keep the cavity full of rock. The weight of the material pushes the rock through the crushing zone.

The Impact Crusher (HSI) shapes material well. Its performance depends on the blow bars and the gap settings.

Blow Bar Material Selection

You cannot use High Chrome bars for every application. High Chrome is hard but brittle. If you process abrasive granite or feed containing iron, High Chrome bars will shatter.

The Sand Making Machine (VSI) operates at high speeds (50-70 m/s). Rotor balance is the most critical factor.

Optimizing Cascade Feed

The VSI allows you to split the feed. Some goes into the rotor (Center Feed). Some falls around the rotor (Cascade Feed).

Lubrication failure is the number one cause of bearing damage. The film of oil or grease separates the metal parts.

Contamination Control

Dust is abrasive. It is harder than steel. You must clean the grease fittings before attaching the grease gun. Ensure oil tanks have breathable filters to keep dust out.

Temperature Monitoring

You should choose liners based on the Abrasiveness Index (Ai) of your ore, not just the price.

| Ore Type | Abrasiveness (Ai) | Recommended Material | Benefit |

|---|---|---|---|

| Limestone | Low (<0.1) | High Chrome | Maximum wear resistance |

| River Gravel | Medium (0.2-0.4) | Mn18Cr2 (High Manganese) | Balance of tough and hard |

| Granite | High (>0.5) | Mn22Cr2 / Ceramic Inserts | Resists high abrasion |

| Tooth Profile Selection | |||

| For jaw crushers, the tooth profile matters. Heavy-duty smooth teeth last longer but consume more power. Sharp teeth crush faster but wear out quicker. You must balance your energy costs against your parts budget. |

The Vibrating Feeder acts as the throttle for your plant. Correct feeding reduces energy waste.

Remove Fines Early

You should use a feeder with a grizzly bar section. This removes soil and small rocks (fines) before they enter the crusher. Fines cushion the large rocks in the crushing chamber. This reduces the crushing effect and wastes energy. Removing fines can increase effective capacity by 20-30%.

Automation for Choke Feeding

You should link the feeder speed to the crusher’s amp draw or level sensor.

Reactive maintenance (fixing broken machines) is expensive. You should switch to predictive maintenance.

Vibration Monitoring

Install simple vibration sensors on bearing housings. A change in vibration amplitude is the first sign of trouble. It detects loose bolts, failing bearings, or an unbalanced rotor weeks before failure.

Daily Inspection Routine

Question 1: How do I know when to replace my jaw crusher toggle plate?

You should inspect it weekly. If you see visible cracks, deformation, or deep scoring on the seating surface, replace it immediately. A worn toggle plate transmits dangerous shocks to the main frame, which costs much more to fix.

Question 2: Why is my cone crusher output size coarser than the setting?

This often happens due to “liner bounce.” If the hydraulic pressure is too low or there is too much non-crushable material (fines) in the feed, the adjustment ring lifts. Check your accumulator pressure and screen out fines before feeding.

Question 3: Can I restart a crusher full of material after a power outage?

No, absolutely not. This is a “stalled start.” It puts massive torque on the motor and shaft, leading to breakage. You must clear the crushing chamber manually or use the hydraulic clearing system (if available) before restarting.

Question 4: What is the best grease to use for crusher bearings?

Always use the grease specified in your ZONEDING manual. Generally, use a Lithium-complex grease with Extreme Pressure (EP) additives (EP2 or EP3). Standard chassis grease melts at high temperatures and will cause bearing failure.

Question 5: How can I reduce dust emissions from my crushing plant?

Ensure your water spray nozzles are clean and positioned at the transfer points (feeder to crusher, crusher to belt). Also, enclose the conveyor belts. Regular maintenance of dust collector filters is essential for keeping suction strong.

Crusher maintenance requires observation, not just tools.

Guide to improving ball mill output. Learn about optimizing grinding media, feed, speed, and liners to achieve maximum productivity and efficiency.

View detailsThe grinding process determines the success of mineral separation. Proper selection of grinding equipment in mining ensures a high liberation degree for mineral particles. This technical guide analyzes ball mills, rod mills, and SAG technology fo...

View detailsEfficient stone processing requires a well-planned Stone Crushing Flow to maximize output and minimize costs. Modern mining operations in 2026 prioritize automation and energy-saving designs. A successful production line relies on the c...

View detailsThe selection of mineral processing dewatering equipment determines the final moisture of your product and waste. Removing water correctly lowers your transport costs and protects the environment. This guide provides a full overview of the dewate...

View details