How to Select a Fluorite Processing Machine?

3793Choosing your fluorite processing equipment? Discover critical factors like ore characteristics, capacity needs, and cost-efficiency to select the best machine.

View detailsSearch the whole station Crushing Equipment

Efficient stone processing requires a well-planned Stone Crushing Flow to maximize output and minimize costs. Modern mining operations in 2026 prioritize automation and energy-saving designs. A successful production line relies on the correct balance between primary, secondary, and tertiary stages. This guide provides a detailed look at equipment configuration for various rock types and production goals. Understanding the flow from raw material to finished aggregate is essential for any high-capacity mining project. Consistent material movement prevents bottlenecks and ensures long-term machine health.

Steady material movement starts with a reliable feeder system. Raw stones must enter the primary crusher at a controlled rate to prevent mechanical overload. An automated feeder adjusts the flow based on real-time sensor data from the main motor. This Feeder Frequency Adjustment keeps the crushing chamber at an optimal level for maximum efficiency. If the feed rate is too high, the machine stops due to blockage. If the feed rate is too low, the plant wastes electricity and potential profit. Consistent feeding is the foundation of a high-capacity Stone Crushing Flow.

Pre-screening is another vital function of the modern feeder. Grizzly bars allow small rocks and soil to bypass the primary crusher. This process is called “scalping.” Scalping reduces the workload on the and prevents mud from clogging the crushing plates. Removing fine material early can increase the total system capacity by nearly 20%. The gap between the grizzly bars must match the discharge setting of the primary machine. Proper maintenance of these bars ensures the raw material stays clean and manageable.

A variable frequency drive (VFD) offers the best control for modern feeders. This technology allows for instant speed changes to match the plant’s needs. Automated sensors detect the pressure in the crusher and signal the feeder to slow down or speed up. This setup removes the risk of human error during peak operation hours. Wear-resistant plates inside the hopper protect the frame from the impact of heavy falling rocks. Durable liners reduce maintenance costs and extend the life of the entire feeding unit.

| Feeder Part | Purpose | Maintenance Tip |

|---|---|---|

| Grizzly Bars | Pre-screen dirt | Replace when gap widens |

| Vibrating Motor | Moves the stone | Check oil every 500 hours |

| Spring Support | Absorbs shock | Replace if cracked or weak |

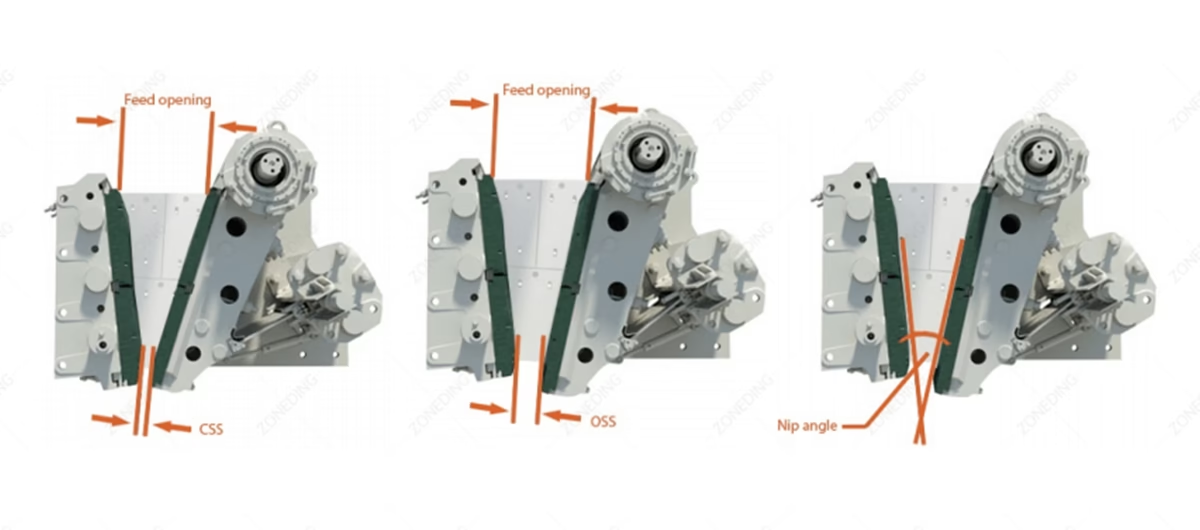

The Jaw Crusher performs the heavy work of the primary stage. This machine breaks large boulders into smaller pieces that fit into secondary equipment. The Closed Side Setting (CSS) determines the size of the output material. A proper Crushing Ratio Calculation ensures the machine operates without excessive stress. Most primary crushers work best with a ratio between 4:1 and 6:1. If the discharge gap is too small, the wear on the jaw plates increases rapidly. If the gap is too large, the secondary crusher becomes overloaded with oversized rocks.

Daily adjustments to the discharge opening are necessary for consistent results. Hydraulic wedges allow for quick changes to the gap without stopping the plant for long periods. Regular monitoring of the jaw plates shows the level of wear on the manganese steel. As the teeth on the plates flatten, the discharge size naturally increases. This change requires the operator to tighten the setting to maintain product quality. A well-adjusted primary stage creates a smooth flow for every machine downstream.

Maintaining an 80% chamber fill level creates the best “rock-on-rock” crushing effect. This technique improves the shape of the stone and reduces direct contact with the steel plates. Rotating the jaw plates upside down is a smart way to double their service life. This simple task uses the less-worn upper part of the plate for the final crushing zone. Also, the maximum feed size should never exceed 85% of the intake opening. This rule prevents large rocks from getting stuck and causing a plant shutdown.

| Setting Factor | Impact on Flow | Recommended Action |

|---|---|---|

| Tight CSS | Small output, high wear | Use only for soft rock |

| Wide CSS | Large output, low wear | Use to maximize capacity |

| Worn Plates | Inconsistent sizes | Check gap every 8 hours |

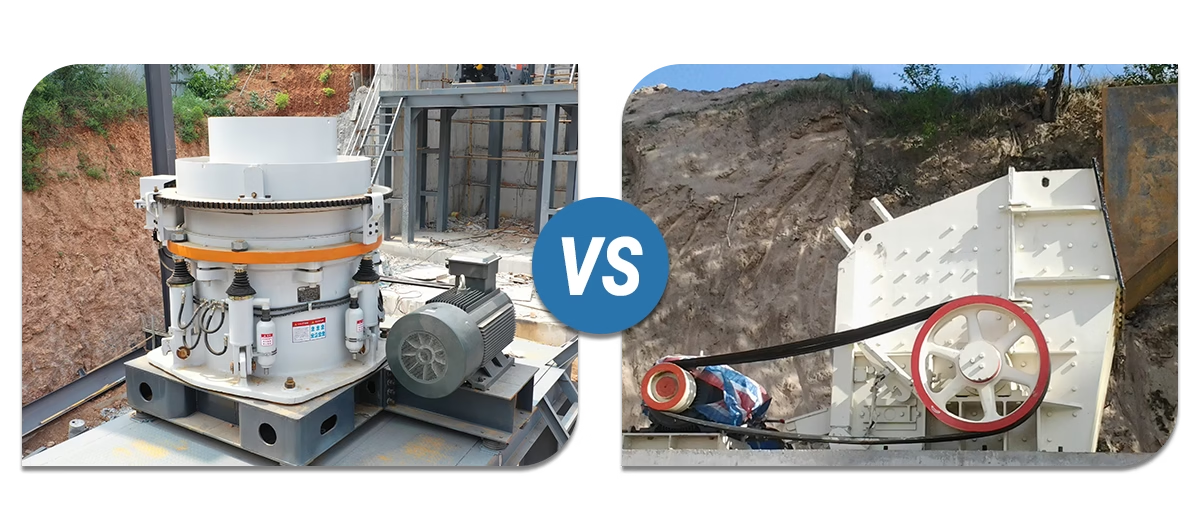

Selecting the right secondary machine depends on the hardness and abrasiveness of the stone. A Cone Crusher is the standard choice for hard materials like basalt, granite, and iron ore. This machine uses compression to break rocks, which is very efficient for tough minerals. Cone crushers provide a stable output size and have low operating costs for abrasive rocks. “Choke feeding” is the best way to run a cone crusher. Keeping the chamber full creates better stone shapes and reduces wear on the internal liners.

An Impact Crusher is better suited for soft or medium-hard stones like limestone. This machine uses high-speed hammers to break rocks by impact force. The main benefit of an impact crusher is the excellent cubical shape of the finished product. These machines have a high reduction ratio, often doing the work of two stages in one. But, high silica content in the rock will wear out the blow bars very quickly. A lab test for rock abrasiveness is the first step before making a final machine choice.

| Feature | Cone Crusher | Impact Crusher | Selection Strategy |

|---|---|---|---|

| Material | Hard / Abrasive | Soft / Non-abrasive | Match to rock test |

| Shape | Good | Superior (Cube) | Impact for road stone |

| Maintenance | Low cost | High cost (on hard rock) | Cone for granite |

Modern cone crushers in 2026 feature hydraulic clearing and setting systems. These tools allow the machine to pass uncrushable objects like metal scrap without damage. For impact crushers, the distance between the blow bars and the apron plates must stay consistent. Regular adjustments maintain the high quality of the crushed gravel. Choosing the correct liner profile for a cone crusher also changes the output size and capacity. Matching the machine to the specific rock type ensures the lowest cost per ton.

The Vibrating Screen acts as the quality control center for the whole plant. This machine separates the crushed stone into different piles based on size. A multi-layer screen deck produces several products at the same time, such as 20mm gravel, 10mm stone, and sand. Precise Vibrating Screen Grading ensures that the finished aggregate meets strict construction standards. If the screening is poor, the final product will contain too many “fines” or oversized pieces. This reduces the market value of the material and can lead to customer complaints.

Screen efficiency depends on the vibration stroke and the angle of the deck. Material should spread evenly across the entire screen surface to maximize the contact time. If the rock moves too fast, small stones do not have time to fall through the holes. If it moves too slow, the screen becomes overloaded and stops vibrating correctly. Polyurethane mesh is a popular choice for 2026 operations because it lasts longer than steel and resists clogging. Maintaining the correct tension on the screen mesh prevents the material from bouncing ineffectively.

| Deck Level | Product Size | Common Use | Target Market |

|---|---|---|---|

| Top Deck | > 40mm | Return to Crusher | Recycled for further crushing |

| Middle Deck | 10-20mm | Concrete Aggregate | Construction companies |

| Bottom Deck | < 5mm | Fine Sand | Asphalt and brick making |

High-quality concrete and asphalt require cubical stone shapes. Sharp or flat stones create weak points in the building material. A Sand Making Machine (VSI) solves this problem by shaping the stone at high speeds. The VSI uses a rotor to throw rocks against a bed of other rocks. This “rock-on-rock” technology breaks off weak edges and produces a perfect cube. This process also creates high-quality manufactured sand, which is a valuable product in 2026 as natural sand becomes scarce.

The speed of the VSI rotor controls the fineness of the sand. A faster rotor creates more sand but increases power consumption. Regular checks on the rotor tips and wear plates are necessary to maintain performance. A VSI crusher also helps in removing soft parts of the rock, leaving only the strongest material for the final product. Using a shaper is the best way to upgrade a standard Stone Crushing Flow into a premium production line. This machine adds significant value to the final aggregate by improving its physical properties.

A closed-circuit system ensures that no oversized material leaves the plant. In this setup, a conveyor belt takes large stones from the top screen deck and sends them back to the secondary crusher. This loop continues until all rocks are small enough to pass through the screen. A closed-circuit Crushing Line Configuration provides 100% control over the maximum product size. This is essential for meeting strict project specifications where even a few large rocks can cause a rejection of the entire load.

The return conveyor must be wide enough to handle the extra volume of the “circulating load.” If the return rate is too high, it indicates that the crusher setting is too open. Most efficient plants aim for a 20% to 30% return rate. This balance keeps the crusher full and produces a better stone shape due to the inter-particle crushing effect. A closed-circuit design increases the total quality of the output and prevents the waste of sellable material. It is the gold standard for modern aggregate production in 2026.

Conveyors move the lifeblood of the plant from one stage to the next. A poor Belt Conveyor Layout leads to spilled rocks and expensive downtime. The angle of the conveyor should generally stay below 18 degrees for crushed stone. If the angle is too steep, rocks will roll backward and cause piles of waste under the belt. Troughing rollers help center the material and prevent side spillage. Properly aligned belts reduce the wear on the rubber and the motor, saving money over time.

Dust and small particles often stick to the belt after the stone is dropped. Belt scrapers must be installed at the discharge end to clean the surface. Without scrapers, this material falls off during the return trip and creates a mess. Impact beds are also necessary at the loading points under the crushers. These beds absorb the energy of falling rocks and protect the belt from tears. A clean and well-maintained conveyor system ensures a safe working environment and a steady Stone Crushing Flow.

Environmental rules in 2026 are very strict regarding dust and noise. Every modern crushing plant must include a dust suppression or collection system. Water sprays are the most common and cost-effective method. Spray nozzles are placed at the crusher inlets and conveyor transfer points. A fine mist traps the dust before it becomes airborne. It is important to use only enough water to dampen the dust without making the stone too wet for the screens.

For dry climates, a baghouse dust collector is a better option. This system uses a powerful fan to suck dusty air through fabric filters. Enclosing the crushers and screens with steel covers also helps contain the noise and dust. Keeping a plant clean protects the health of the workers and prevents mechanical wear in the bearings. An environmentally friendly plant is easier to permit and creates a better relationship with the local community.

The industry is moving toward “Smart Mining” and greener operations. Artificial intelligence (AI) now monitors the rock size on conveyors using 3D cameras. The AI automatically adjusts the Cone Crusher settings to keep the product within the target range. This technology maximizes the yield of the most profitable sizes. Also, Mobile Crushing Stations are becoming more popular for infrastructure projects. These units can be moved closer to the work site to reduce trucking costs.

Q1: How do I choose the best primary crusher for soft rock?

For soft rocks like limestone, an Impact Crusher is often the best choice for the primary stage. It provides a higher reduction ratio and better shape than a jaw crusher in these specific materials.

Q2: What causes a bottleneck in the stone crushing flow?

Bottlenecks usually happen at the screen or the secondary crusher. If the screen is too small, it cannot process the volume from the crusher. Always size the screen 20% larger than the expected feed rate.

Q3: Can a VSI crusher make sand from hard granite?

Yes, a VSI is excellent for making granite sand. Use a “rock-on-rock” rotor configuration to keep the wear costs low on such hard material.

Q4: Why is my vibrating screen making a loud banging noise?

Check the tension of the screen mesh. If it is loose, the mesh will hit the support frame. Also, check the springs and the motor mount bolts for any cracks or loose parts.

ZONEDING is a professional manufacturer of mining and crushing equipment based in China. Since 2004, the company has provided high-performance machines to over 120 countries. The product range includes Mobile Crushers, Ball Mills, and complete Mineral Processing Plants. With a team of 15 specialized engineers, ZONEDING designs custom solutions for mining and aggregate production. The factory direct sales model ensures competitive pricing and reliable after-sales service.

Contact ZONEDING today to get a custom design and a free quote for your next stone crushing project.

Choosing your fluorite processing equipment? Discover critical factors like ore characteristics, capacity needs, and cost-efficiency to select the best machine.

View detailsEquipment choice impacts everything. This guide breaks down the 5 essential factors for selecting lithium ore processing equipment for optimal recovery rates.

View detailsReady to find gold? This guide explains how placer deposits form, how to identify different types, and the essential mining methods from panning to sluicing.

View detailsDiscover the 7 crucial aspects of mobile crushing technology, from its benefits and applications to key operational considerations for peak efficiency.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy