What is a Ball Mill and How Does It Work?

3965Get an understanding of what a ball mill is, its fundamental components, and the detailed mechanism behind its efficient grinding process for various materials.

View detailsSearch the whole station Crushing Equipment

Processing graphite in 2026 is a specialized task. I always tell my clients that it is a battle to save the flakes. The value of your product depends on the size of the crystal flakes. If you grind too much, you lose money. Large flakes are for high-end markets like fire retardants. Fine powder is for batteries. I will show you how to design a line that keeps flakes big and purity high. Success comes from the right balance of crushing, grinding, and flotation stages.

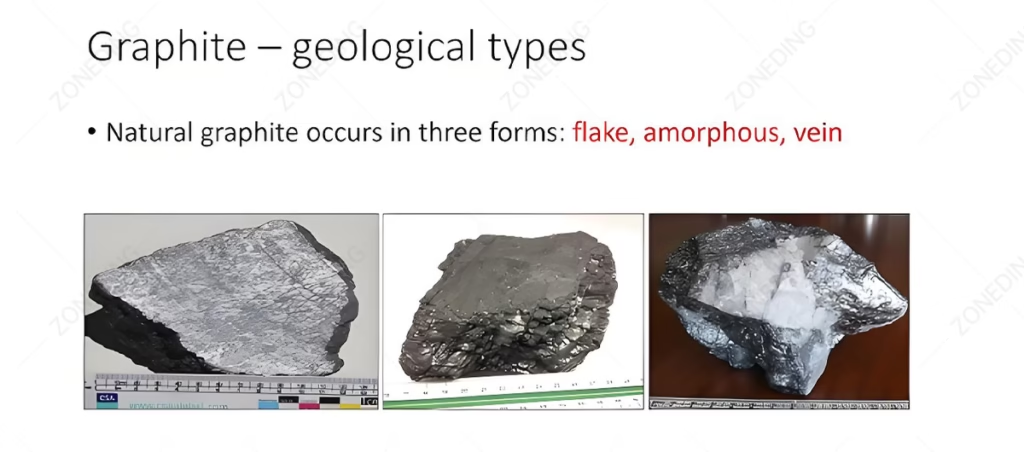

Crystalline graphite and amorphous graphite have different shapes and market values. Crystalline graphite looks like shiny flakes. These flakes are thin and flat. They have a metallic luster. This type is very easy to float. It is naturally greasy and rejects water. I see a huge demand for this type in 2026. It is the main material for lithium-ion battery anodes. Protecting the flake size is the most important part of the Graphite processing equipment setup. If the flakes break, the price drops.

Amorphous graphite is different. It looks like black soot. The crystals are so small you cannot see them with your eyes. It often mixes with clay or coal. It does not feel as slippery as flake graphite. Processing this type is harder. The impurities are tiny and stuck to the graphite. Most mines use this for pencils or lubricants. You must know your ore type before you buy any machines. I recommend a laboratory test first. This test tells us the carbon grade and the flake distribution. It helps us decide the crushing force and the grinding time.

| Property | Crystalline (Flake) | Amorphous (Microcrystalline) | Impact on Your Plant |

|---|---|---|---|

| Visual | Shiny, flat plates | Dull, black powder | Flake needs gentle handling |

| Carbon % | 3% to 15% (Raw) | 60% to 90% (Raw) | Amorphous starts with higher grade |

| Market Use | EV Batteries, Gaskets | Pencils, Steel Casting | Flake has much higher value |

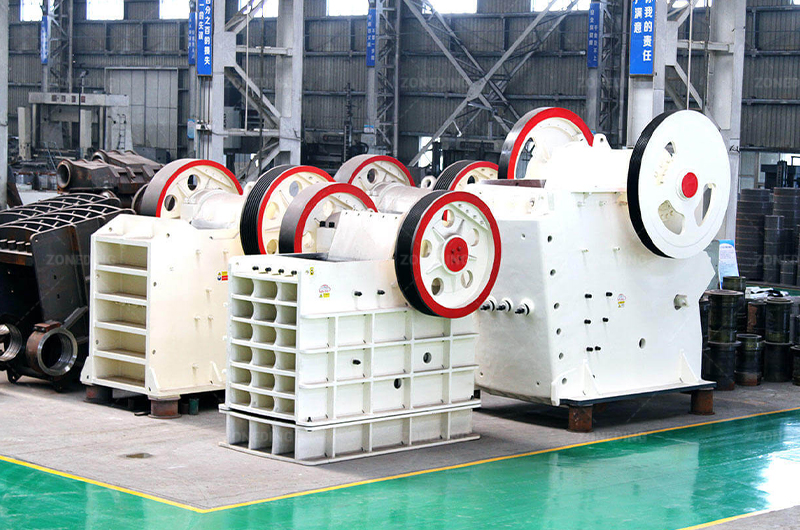

The goal of crushing is to make the rocks small enough for the mill. But you must not crush the graphite flakes inside the rocks. I always suggest a Jaw Crusher for the first stage. This machine uses a simple squeeze. It breaks large rocks into smaller pieces without too much friction. It is a very reliable machine. Modern versions have hydraulic systems. You can change the output size in seconds. This helps keep the production flow steady.

For the second stage, an Impact Crusher is usually the best choice. This machine hits the rocks at high speed. It makes the rocks break along their natural lines. This separates the graphite from the waste rock. It is better than a cone crusher for soft minerals like graphite. Sometimes, a Hammer Crusher is used if the ore is very brittle. I prefer a “short and fast” crushing circuit. You should use a vibrating screen between the stages. This screen removes the small stones early. It prevents the machines from over-processing the material.

Multi-stage grinding is the secret to a successful graphite mine. If you grind everything to a powder at the start, you lose the big flakes. I call this the Graphite multi-stage grinding strategy. In the first stage, the mill only grinds the ore a little bit. It releases about 40% of the graphite. This mixture goes to the first flotation stage. The large flakes that are already free will float to the top. We take them out of the system immediately. This keeps them safe from more grinding.

The stones that still have graphite inside go to a second mill. This mill grinds them a little more. This cycle repeats 4 to 10 times. It is a long process, but it is worth it. I highly recommend using a Rod Mill for the first grind. Steel rods provide line contact. They peel the rock layers apart. This is much better than steel balls. Steel balls hit the flakes and break them. For the later stages, you can use a Ball Mill or a vertical stirred mill. These machines use rubbing to clean the waste off the flakes.

| Stage | Machine Choice | Grinding Action | Benefit |

|---|---|---|---|

| Primary | Rod Mill | Line Peeling | Saves 80% of large flakes |

| Regrind 1 | Ball Mill | Impact / Rubbing | Breaks up mixed particles |

| Regrind 5+ | Stirred Mill | Surface Scrubbing | Increases purity to 95% |

| “Learn more about our Rod Mill solutions for flake protection.” |

Graphite floats very well by itself. It likes air bubbles and hates water. But it is also “sticky.” It often carries mud and sand with it to the surface. To get a 95% grade, you need many stages of cleaning. A standard 2026 Graphite flotation process includes one roughing stage and up to ten cleaning stages. The roughing stage is about “recovery.” We want to catch every bit of graphite. The cleaning stages are about “quality.” We want to wash away the dirt.

I suggest using a Flotation Machine with a gentle impeller. High-speed mixing can tear the flakes. Between the cleaning stages, we often add a small mill. This mill “scrapes” the dirt off the surface of the flakes. I also recommend using Mixer tanks to prepare the chemicals. You need kerosene to catch the graphite and pine oil to make the bubbles. Adding these chemicals in the right amount is very important. Too much oil will make the foam too thick. This will trap mud and lower your grade.

Flotation can usually reach 95% or 96% purity. But battery makers want 99.9%. To reach this, you must use Graphite purification technology. The most common method is acid leaching. We soak the graphite in acids like Hydrofluoric acid or Hydrochloric acid. These chemicals dissolve the silica and iron that flotation could not remove. The graphite itself is not affected by the acid. It stays solid while the impurities turn into liquid.

Another method is the alkaline-acid process. First, we mix the graphite with sodium hydroxide. We heat it to 600 degrees Celsius. This turns the silica into a salt that dissolves in water. Then we use a small amount of acid to clean the rest. This method is very effective. For the highest purity, some use thermal purification. They heat the graphite to 2,500 degrees Celsius in a vacuum. Every other mineral turns into gas and disappears. This leaves only the carbon. This is the most expensive method but gives the best results.

| Method | Carbon Purity | Main Advantage | Best For |

|---|---|---|---|

| Acid Leaching | 99.9% | Very reliable | Battery anodes |

| Alkaline-Acid | 99.9% | Safer than pure HF acid | Industrial use |

| Thermal | 99.999% | Extreme purity | Nuclear / Electronics |

Matching the capacity of your machines is a big job. If the Ball Mill is too big, it will flood the flotation cells. If the flotation cells are too big, the foam will not be deep enough. I always look at the volume of the pulp. Graphite is very light. It takes up more space than gold or copper. This means your Flotation Machine must be 20% larger than a standard machine for the same tonnage.

You also need a way to control the size of the particles. I recommend using a Spiral Classifier or a Hydrocyclone. These machines send the big pieces back to the mill. They only let the small pieces go to the flotation cells. This keeps the process stable. In my experience, a closed-circuit system is always better. It prevents over-grinding and saves energy. At ZONEDING, we can design the whole layout for you. We make sure every machine works perfectly with the next one.

Once the graphite is clean, it is very wet. You must remove the water before you can sell it. The first step is a High Efficiency Concentrator. This is a large tank where the graphite settles to the bottom. The clean water at the top can be reused in the factory. This saves a lot of water. The thick mud at the bottom then goes to a filter press. This machine squeezes out most of the remaining water.

The final step is a Rotary Dryer. You must be careful here. Graphite dust is a conductor of electricity. If it gets into your electric motors, it will cause a short circuit. I always tell my clients to put the dryer in a separate room. You should also use a “baghouse” to catch the dust. This prevents pollution and saves your product. We offer specialized dryers that use indirect heat. This keeps the graphite from burning or changing its structure.

The grade of your graphite tells you who will buy it. Large flakes (+50 mesh) are very valuable. They are used for “expandable graphite.” When you heat this graphite, it grows like popcorn. It is used to stop fires in buildings and planes. It is also used to make high-end gaskets for cars. If you have these big flakes, you will have high profits.

Fine powder (-100 mesh) is the most common product. After it is cleaned and shaped into small balls, it goes into batteries. This is called “spherical graphite.” The 2026 market for this is growing fast because of electric cars. Low-grade graphite (under 80% carbon) is still useful. It is sold to steel mills. They use it as a lubricant or to line the inside of hot furnaces. I always suggest having a plan for every grade your mine produces.

| Grade | Market Name | Use in 2026 |

|---|---|---|

| +50 Mesh | Jumbo Flake | Fire Retardants, Aerospace |

| +80 Mesh | Large Flake | Gaskets, Heat Management |

| -100 Mesh | Fine Powder | EV Batteries, Pencils |

The biggest trend I see is the move toward “Zero-Iron” plants. Battery makers do not want any iron in their graphite. Even a tiny bit can cause a battery to catch fire. This means we are now using Ceramic Ball Mills and ceramic-lined pipes. This prevents the steel from the machines from touching the graphite. It is a more expensive setup, but the product sells for a much higher price.

Another trend is AI control. We now use cameras to look at the flotation foam. The computer can see if the bubbles are the right size. It can change the chemical dosage automatically. This reduces waste and keeps the grade very steady. I believe every new mine should look at these smart technologies. They make the operation much easier and safer for the workers.

Q1: Can I use a standard ball mill for the whole graphite process?

I do not recommend it. A standard mill will break your big flakes. You should use a Rod Mill for the first stage and specialized stirred mills for the later stages.

Q2: Is the acid leaching process dangerous for the environment?

It can be. You must have a good water treatment plant. You must neutralize the acid before you release the water. We can help you design a safe system.

Q3: How much does a complete Graphite processing equipment line cost?

The price depends on the tonnage. A small 10-ton per hour line is much cheaper than a 100-ton line. I suggest sending us your ore report for a custom quote.

Q4: Why is my graphite grade not reaching 95%?

You probably need more cleaning stages. Most plants need 8 to 10 stages. You also need to check your regrinding size. If the particles are too big, the waste stays trapped inside.

ZONEDING is a professional manufacturer of mining machinery in China. We focus on B2B solutions for mining companies and aggregate producers. We offer a full range of products from Jaw Crushers to Flotation Machines. Our factory covers 8,000 square meters and we have 15 professional engineers. We have exported our equipment to 120 countries. We provide full-service support, including design, installation, and training.

Contact us today for a free design and a competitive price on your graphite production line.

Get an understanding of what a ball mill is, its fundamental components, and the detailed mechanism behind its efficient grinding process for various materials.

View detailsCapital expenditure (CapEx) for comminution circuits typically exceeds 50% of a mineral processing plant's total investment, with operational expenditure (OpEx) frequently surpassing 60%. Consequently, the strategic configuration of Crushing...

View detailsLearn exactly how silver mining works with our step-by-step guide. We break down the complete process, from ore exploration and mining to final refining.

View detailsDesign a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy