High-Yield Placer Gold Scheme: A Blueprint for Maximum Profit

3538Unlock maximum gold recovery. Our guide details a high-yield, high-enrichment placer gold processing scheme, from screening to final concentration.

View detailsSearch the whole station Crushing Equipment

The industrial wet ball mill is a critical machine for modern mining. It grinds rocks into a fine powder using water and steel balls. This process consumes a large amount of electricity. Picking the wrong size leads to high costs and low production. A correct choice in 2026 ensures high profit and steady operations. This guide explains how to evaluate different models for various mineral types. Success starts with understanding the machine and the material.

The is the machine where mineral liberation occurs. Most valuable minerals exist inside waste rock as tiny particles. The ball mill breaks these rocks to release the minerals. If the grinding is poor, the minerals stay trapped. Then the next stage of Beneficiation Equipment fails to collect them. This leads to wasted resources and lost money. The mill must achieve the target size for the specific ore.

This machine is the most expensive part of a factory to run. It uses nearly half of the total power in a mining plant. A small error in selection causes a permanent bottleneck. If the mill is too small, the whole factory slows down. If the mill is too large, it wastes power and water. Every ton of rock processed must meet the quality standards of the market. The Ball Mill determines the final output quality. It moves the slurry to the Flotation Machine or magnetic separator.

| Ore Category | Grinding Target | Recovery Impact | Practical Application |

|---|---|---|---|

| Gold Ore | 85% -200 mesh | Very High | Releases tiny gold grains |

| Copper Ore | 70% -200 mesh | High | Prevents coarse losses |

| Iron Ore | 90% -325 mesh | High | Increases concentrate purity |

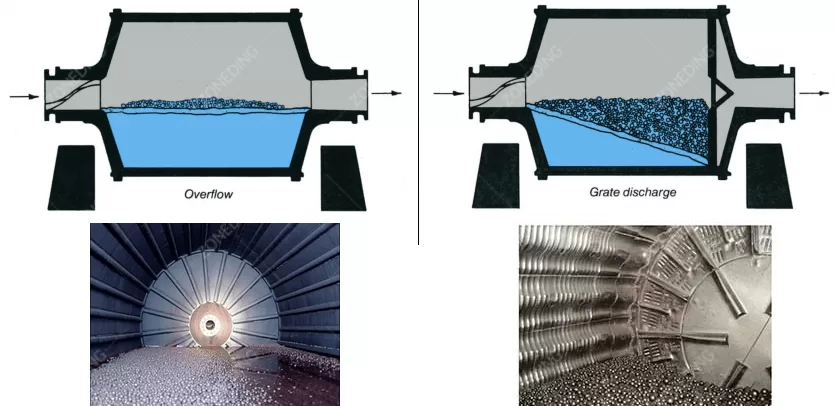

The discharge method defines how the ground mud leaves the machine. An Overflow type ball mill has a simple design. The mud flows out naturally when it reaches the exit level. This means the mud level inside the drum remains high. This design is perfect for fine grinding. The rocks stay inside for a longer time. The steel balls have more time to rub and crush the ore. It is common in the second stage of a Beneficiation Equipment line.

A grate discharge ball mill has a metal screen at the end. A special mechanism forces the mud through the screen. This keeps the mud level inside the drum very low. This type handles larger rocks better than the overflow type. It processes more tons of ore per hour. The fast exit prevents over-grinding of the particles. Over-grinding wastes energy and chemicals. Grate mills are the standard for the first stage of grinding. Regular cleaning of the grate screen is necessary to prevent clogs.

Liners protect the expensive drum from the constant hitting of steel balls. The choice of material depends on the hardness and size of the rocks. High-manganese steel is the classic choice for hard rocks. This metal becomes harder as it receives heavy impacts. It handles rocks larger than 30mm with ease. Steel liners last a long time in primary grinding stages. However, they are heavy and difficult to replace.

Rubber liners are a modern alternative for fine grinding. Rubber is much lighter than steel. This makes the installation process safer and faster. Rubber also reduces the noise level of the factory. It resists acid and chemicals in the mine water. But rubber is not suitable for large or sharp rocks. Sharp edges cut the rubber into pieces. Most successful plants use steel for the first mill and rubber for the second. This strategy balances cost and protection effectively.

| Liner Type | Rock Hardness | Feed Size | Primary Benefit |

|---|---|---|---|

| Manganese Steel | Hard / Abrasive | >25mm | High impact resistance |

| Rubber | Medium / Soft | <10mm | Low noise and light weight |

| Alloy Steel | Medium | 10-25mm | Good wear life for sand |

Grinding efficiency depends on the rotation speed and the ball size. The drum must spin at the correct speed to lift the balls. Most mills operate at 70% to 80% of the critical speed. At this speed, balls fall on the rocks with maximum force. If the speed is too low, balls just roll on the bottom. This wastes electricity. If the speed is too high, centrifugal force keeps balls against the wall. A Variable Frequency Drive (VFD) allows for precise speed control.

The size of the steel balls is another vital factor. Large balls are needed to break large rocks. Small balls are needed to grind small particles into powder. A mix of different sizes is usually the best approach. This fills the gaps inside the drum and increases contact area. More contact means more grinding in less time. Water content also plays a role. Too much water makes the mud too thin to stick to the balls. Proper water control keeps the efficiency high.

Energy is the largest operating cost for an industrial wet ball mill. The motor must pull the heavy weight of the balls and the rock. Many operators put too many balls in the drum. They think more balls mean more production. This is often false. If the drum is more than 45% full, the balls hit each other. This wastes power and destroys the balls. Keeping the filling rate between 35% and 40% is the most efficient choice for 2026.

The quality of the balls also affects the energy bill. Broken or flat balls stay at the bottom of the drum. They take up space and use power but do not grind any rock. A monthly “screening” of the balls is a good practice. Remove all the small fragments and scrap metal. Only add round, high-quality steel balls. This reduces the dead weight. The motor works less to achieve the same grinding results. This is the simplest way to lower the monthly power bill.

| Filling Rate | Grinding Ability | Power Cost | Best Use Case |

|---|---|---|---|

| 30% | Low | Low | Soft materials / Small scale |

| 40% | Optimum | Medium | Standard mining operations |

| 50% | High | Very High | Heavy duty / Hardest ores |

Density control is the secret to high throughput. The mud inside the mill must have the right thickness. If the mud is too thin, the balls hit the liners directly. This breaks the machine and makes a lot of noise. If the mud is too thick, it forms a cushion. This cushion stops the balls from hitting the rock. The goal is to have the mud stick to the balls in a thin layer. This ensures that every hit from a ball crushes a piece of rock.

Frequent sampling is the only way to maintain density. A technician should weigh a liter of mud every hour. If the weight is too low, add more rock or less water. If the weight is too high, add more water. Automatic systems can do this using sensors. A steady mud density also helps the next stage of processing. The Hydrocyclone works better when the feed is consistent. This improves the overall recovery of the plant.

The industry is moving toward larger machines and smart technology in 2026. Many new mines now use mills with a diameter over 4 meters. Large mills are more efficient because they process more rock with one motor. This simplifies the maintenance and reduced the total number of spare parts. However, these giant machines require very strong foundations. Deep concrete work is essential before installation.

Smart sensors are the biggest change for 2026. Modern mills have vibration and sound sensors. These sensors tell the operator if the mill is too full or too empty. A computer can adjust the feed speed automatically. This “Smart Grinding” prevents human error and saves money. Remote monitoring is also popular. A manager can check the mill performance on a smartphone from any location. ZONEDING focuses on these digital solutions to help mines stay competitive.

Gears and bearings carry the entire weight of the rotating mill. These parts must be lubricated at all times. Modern mills use a “Static Oil” system. This system pumps oil into the bearings before the motor starts. This creates a thin film of oil that protects the metal surfaces. It prevents damage during the most difficult part of the operation. Without this system, the bearings would wear out in a few months.

Dust and dirt are the enemies of the large gears. A small amount of sand in the gear grease acts like sandpaper. It will eat through the metal in a short time. A sealed gear cover is necessary to keep the area clean. The grease should be checked for metal flakes every week. If flakes are found, the gears are not aligned correctly. Fix the alignment immediately to avoid a very expensive repair. Proper care allows gears to last for twenty years or more.

Calculating the right size requires the Bond Work Index (BWI). This index measures how much energy is needed to grind a specific rock. A lab test provides this number. After finding the BWI, the daily tonnage target must be set. A formula then determines the total kilowatt power required. The drum dimensions must match this power level. It is a mistake to guess the size based on other mines. Every rock is different.

Buying a slightly larger mill is usually a smart move. A machine running at 80% capacity lasts much longer than one at 100%. It also allows for future expansion of the mine. If the production needs to increase, the mill is already ready. ZONEDING engineers help with these calculations. They ensure the motor and the drum work together perfectly. This prevents a mismatch that could lead to motor failure or low production.

| Daily Target (Tons) | Recommended Size | Motor Power (kW) | Application |

|---|---|---|---|

| 200 | 1.5m x 3.0m | 95 | Small Gold Mine |

| 1000 | 2.7m x 4.0m | 400 | Medium Copper Mine |

| 5000 | 4.5m x 6.4m | 2500 | Large Iron Mine |

Question 1: Can a wet ball mill operate without water in 2026?

No. A wet mill is designed for slurry. Operating it dry will cause extreme heat. The liners and the drum may warp or crack. A dedicated dry ball mill is required for dry grinding.

Question 2: How often should new steel balls be added?

New balls should be added daily. Calculate the consumption rate based on the tons of ore processed. Adding a small amount every day keeps the grinding power consistent.

Question 3: What is the average lifespan of a rubber liner?

In a fine grinding stage, rubber liners can last 12 to 18 months. This depends on the abrasiveness of the ore. They last much longer than steel in soft rock applications.

Question 4: Why is my mill making a high-pitched ringing sound?

This sound usually means the mill is empty. The steel balls are hitting the steel liners with nothing in between. Increase the ore feed or decrease the water immediately to protect the machine.

Question 5: Does the motor need a cooling system?

Yes. Large motors generate significant heat. A cooling fan or a water-cooling jacket is necessary to prevent the motor from burning out during long shifts.

ZONEDING is a professional manufacturer of mining machinery in China. The company specializes in B2B sales of Ball Mill products and complete production lines. With a large factory and 15 expert engineers, ZONEDING offers custom solutions for mining and aggregates. The products have reached customers in over 120 countries. Services include design, manufacturing, installation, and after-sales support. ZONEDING provides direct factory prices and high-quality equipment for global projects.

Unlock maximum gold recovery. Our guide details a high-yield, high-enrichment placer gold processing scheme, from screening to final concentration.

View detailsCapital expenditure (CapEx) for comminution circuits typically exceeds 50% of a mineral processing plant's total investment, with operational expenditure (OpEx) frequently surpassing 60%. Consequently, the strategic configuration of Crushing...

View detailsTungsten is a strategic metal characterized by its extreme density and brittleness, often described in mineral processing as "heavy as iron but fragile as glass." The successful extraction of this metal depends entirely on correctly identifying t...

View detailsHard rock crushing presents significant operational challenges. It demands efficient and cost-effective solutions. Traditional crushing methods often struggle with energy consumption and wear. Modern offers better alternatives. High-Pressure Grin...

View detailsWe use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy