Limestone Crushing Plant Blueprint: Design a Profitable Line

3552Design a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsSearch the whole station Crushing Equipment

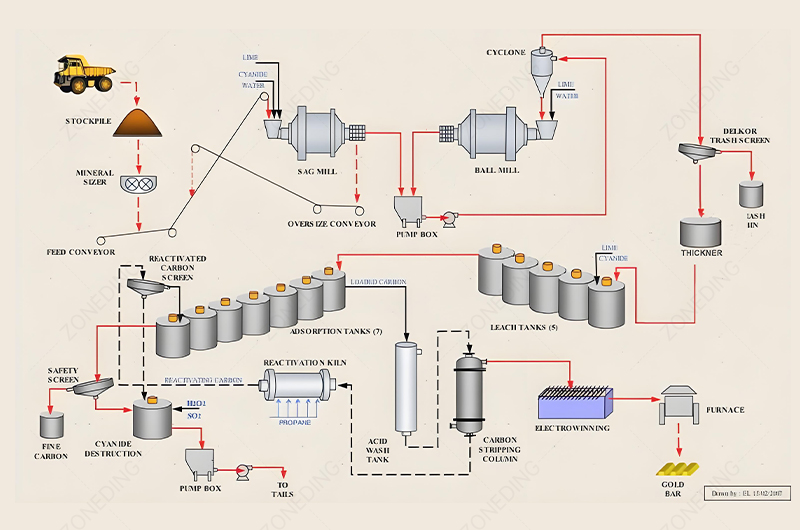

With extensive experience in the field of gold metallurgy and mineral processing engineering, ZONEDING often observes mining operations lose gold not because of poor chemistry, but due to poor carbon management. The Carbon-In-Pulp (CIP) process appears simple, but the physical handling of carbon and slurry determines profitability. This article explains the technical details of the CIP process and discusses how ZONEDING designs these systems to prevent the loss of gold-loaded carbon fines and maximize recovery rates.

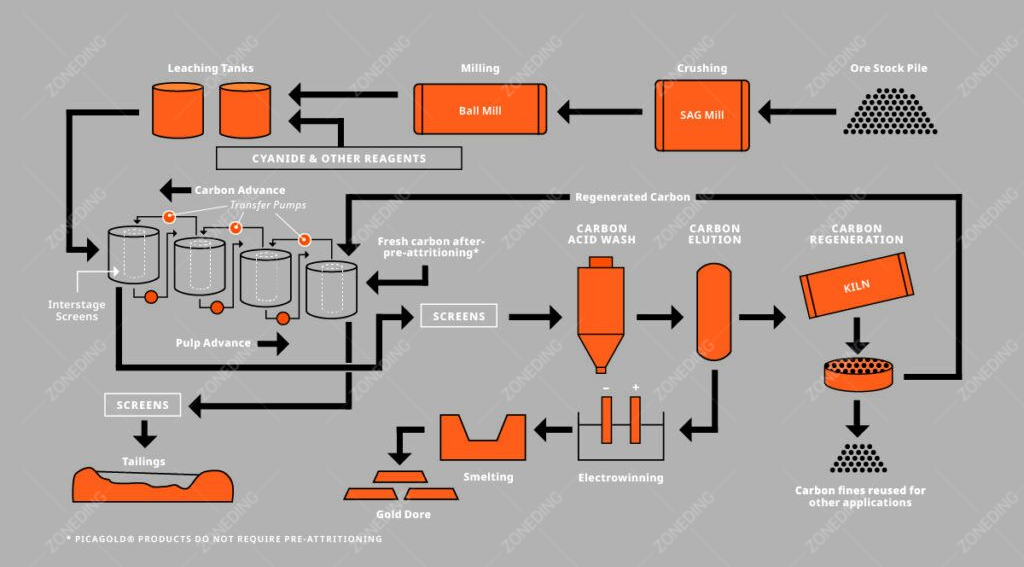

The Carbon-In-Pulp (CIP) process is a gold extraction technique where activated carbon adsorbs dissolved gold from the ore pulp after the leaching stage is complete. This distinguishes it from the Carbon-In-Leach (CIL) process, where leaching and adsorption occur simultaneously. In CIP, the gold first dissolves into the solution in a series of leaching tanks. The slurry then flows into a separate adsorption circuit where activated carbon recovers the gold.

The CIP process relies on the high affinity of activated carbon for gold cyanide complexes. The system operates on a counter-current principle. The ore slurry flows by gravity from the first tank to the last tank. The activated carbon moves in the opposite direction, from the last tank to the first tank. This arrangement ensures that the freshest carbon encounters the lowest concentration of gold in the tail end of the circuit. This maximizes the adsorption driving force and reduces the gold content in the final tailings to the lowest possible level. This physical separation of leaching and adsorption allows operators to optimize the conditions for each stage independently.

To achieve high recovery rates, you must manage the flow of materials and chemicals precisely. The CIP process consists of six specific operational stages.

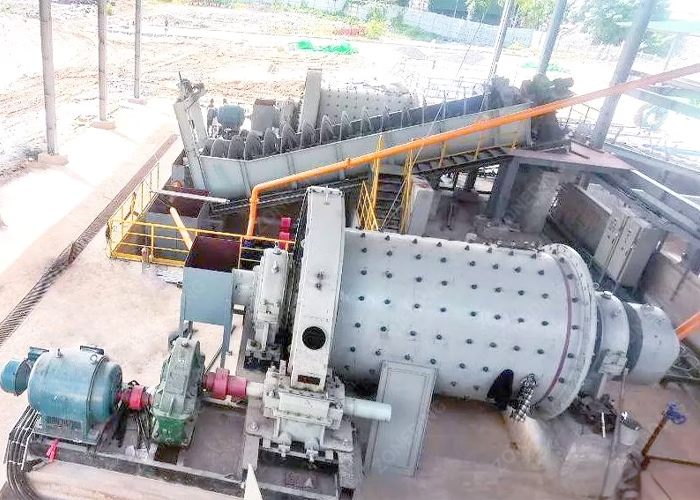

The first step is reducing the ore size to liberate the gold particles. The chemical reaction cannot occur if the cyanide cannot contact the gold. We typically grind the ore until 80% of the particles pass through a 200-mesh screen (74 microns). The process begins with crushing and moves to a two-stage grinding circuit. The ore passes through a primary mill and then a classification system. We use a Hydrocyclone to separate fine particles from coarse particles. The coarse particles return to the Ball Mill for regrinding.

You must remove trash materials before the slurry enters the leaching tanks. Wood chips, plastic, and plant roots enter the mill with the ore. These organic materials absorb gold and block the inter-stage screens in the adsorption tanks. If you do not remove this trash, it causes mechanical blockages and gold loss. We install high-frequency linear vibrating screens to remove this debris. The clean, thickened slurry then moves to the leaching circuit. This preparation ensures the downstream equipment operates without physical obstruction.

The prepared slurry enters a series of agitation tanks. We add sodium cyanide (NaCN) and lime to the slurry. The lime maintains the pH level above 10.5 to prevent the formation of toxic hydrogen cyanide gas. The cyanide dissolves the solid gold particles into a gold-cyanide complex in the liquid phase. The efficiency of this stage depends heavily on the dissolved oxygen levels.

Many operations fail to maintain sufficient dissolved oxygen. Standard air blowers often only achieve 8 ppm of dissolved oxygen. If the ore contains oxygen-consuming minerals like pyrrhotite, this level is insufficient. This results in slow leaching rates and high cyanide consumption. I recommend the use of high-shear reactors or pure oxygen injection systems. Increasing the dissolved oxygen to 20 ppm accelerates the reaction kinetics. This reduces the required residence time in the tanks. It also reduces cyanide consumption by up to 30%. This adjustment significantly lowers the operating cost per ton.

The leached slurry flows into the adsorption tanks. Here, we add coconut shell activated carbon to adsorb the gold from the solution. The management of carbon hardness is the most critical factor in this stage. New carbon is brittle and has sharp edges. If you add fresh carbon directly to the CIP tanks, the agitators will grind these edges off. This creates fine carbon dust loaded with gold. These fines are too small for the retention screens to catch, and they exit with the tailings.

You must perform “pre-attrition” on all new carbon. This involves agitating the new carbon in water for 24 hours in a separate tank. You then screen out the generated fines before adding the carbon to the main circuit. This step prevents significant invisible gold loss. Furthermore, the choice of inter-stage screens determines operational continuity. I advise against vibrating screens as they cause high carbon wear. Air-swept cylindrical screens are superior. They use air pulses to keep the screen surface clean. This prevents blinding and reduces the mechanical stress on the carbon particles.

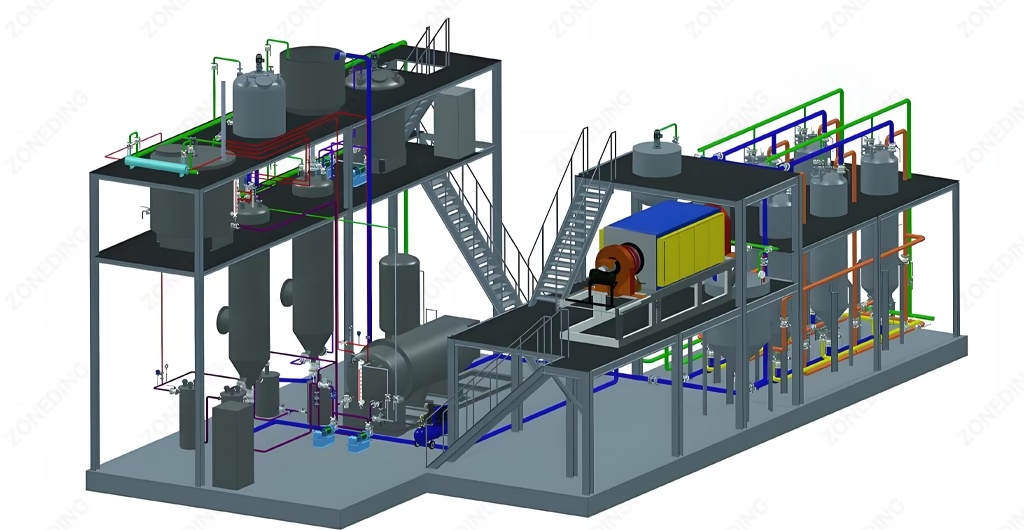

When the carbon reaches the first adsorption tank, it is loaded with gold (typically 3,000 to 8,000 g/t). You must remove the carbon from the slurry and wash the gold off into a concentrated solution. This process is called desorption or elution. Traditional atmospheric desorption methods take up to 72 hours to complete. This slow turnover requires a large inventory of carbon and large equipment.

We recommend a high-temperature, high-pressure desorption system. This system operates at 150°C and 0.5 MPa pressure. These conditions reduce the desorption time to approximately 12 hours. This rapid cycle time allows you to process more carbon with smaller equipment. The high temperature also provides a secondary benefit. It cleans the carbon pores more effectively than lower temperatures. This results in cleaner carbon returning to the circuit. A Gold CIL Plant or CIP plant’s efficiency relies on how quickly you can recycle the carbon.

| Desorption Method | Temperature | Time Required | Efficiency |

|---|---|---|---|

| Atmospheric Zadra | 95°C | 48-72 Hours | Low |

| High-Pressure Zadra | 140°C-150°C | 12-14 Hours | High |

| AARL Process | 110°C-130°C | 8-12 Hours | High |

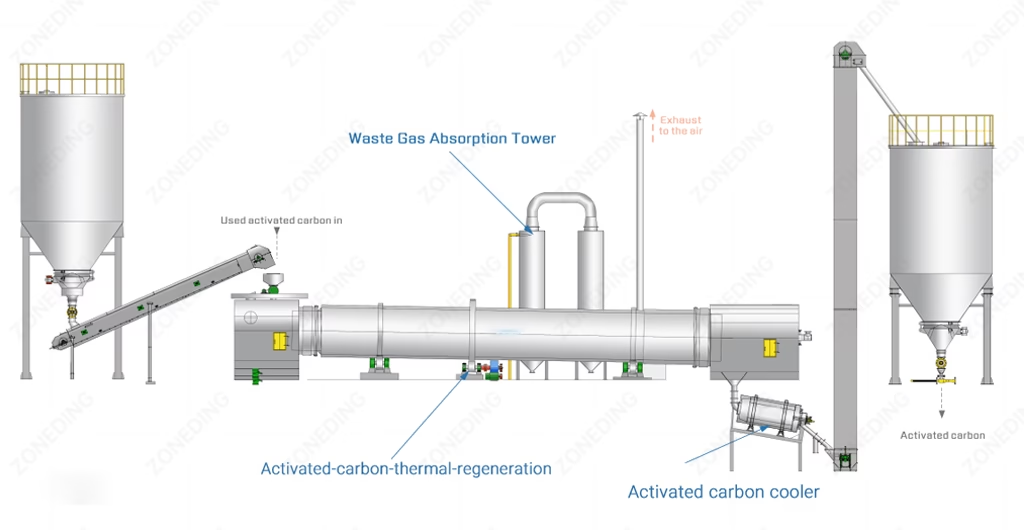

Activated carbon loses its activity over time due to fouling. Calcium carbonate, magnesium, and organic oils clog the micropores of the carbon. You cannot simply reuse the carbon without treatment. The regeneration process consists of two steps: acid washing and thermal regeneration. You must perform acid washing with dilute hydrochloric acid or nitric acid. This removes the inorganic calcium scale. If you skip this, the calcium will fuse to the carbon during the heating stage.

The second step is thermal regeneration in a rotary kiln. You must heat the carbon to 650°C-750°C. It is essential to inject steam during this process. The steam activates the carbon by gasifying the organic impurities trapped in the pores. If you only heat the carbon without steam, you are drying it, not regenerating it. Proper regeneration restores the carbon to over 95% of its original activity. This maintains the adsorption kinetics in the CIP circuit and prevents high tailing grades.

The pregnant solution from the desorption column contains a high concentration of dissolved gold. We pump this solution through an electrowinning cell. The cell contains cathodes made of stainless steel wool. We apply a direct current, which causes the gold to plate out onto the steel wool. This produces a gold sludge.

Operators periodically wash the gold sludge from the cathodes. We filter this sludge and dry it. The final step takes place in a smelting furnace. We melt the sludge with fluxes like borax and silica to remove impurities. The molten gold is poured into molds to form bullion bars. This final product is ready for sale to refineries. The entire Precious Minerals recovery section must be secure to prevent theft.

You should choose the CIP process when dealing with ore that has high leaching kinetics and contains low levels of interfering contaminants like carbonaceous matter or silver. CIP is the standard choice for simple, non-refractory gold ores where the leaching time and adsorption time differ significantly.

The primary advantage of CIP is the ability to optimize tank sizes. Leaching often requires a longer residence time than adsorption. In a CIP plant, the leaching tanks can be large to accommodate the slow dissolution rate. The adsorption tanks can be smaller because the carbon adsorption reaction is fast. This reduces the capital investment in activated carbon inventory and equipment size.

Another advantage is the efficiency of the screens. In CIP, the screens are only located in the adsorption tanks. In CIL, screens are in every tank. CIP reduces the number of screens you need to maintain. It also reduces the amount of carbon that suffers from mechanical abrasion, as the carbon resides in fewer tanks for a shorter duration compared to CIL.

The decision between CIP and Carbon-In-Leach (CIL) depends on the mineralogy of the ore. While the equipment looks similar, the chemical environment dictates the choice. The main factor is the presence of “preg-robbing” materials in the ore.

1. Preg-Robbing Ores:

Some gold ores contain natural organic carbon (like graphite or carbonaceous shale). This natural carbon acts like activated carbon. It adsorbs the gold as soon as it dissolves. If you use CIP, the natural carbon will steal the gold during the leaching stage before the slurry reaches your activated carbon tanks. This gold ends up in the tailings. In this scenario, you must use CIL. In CIL, you add activated carbon to the leaching tanks. The activated carbon competes aggressively with the natural carbon to adsorb the gold.

2. Silver Content:

If the ore contains a high ratio of silver to gold, CIL is often preferred. Silver loads onto carbon and takes up space. High silver content requires a very high carbon advancement rate. Managing this high flow rate is often easier in a CIL circuit where the carbon inventory is distributed throughout the entire tank farm.

3. Merrill-Crowe Process:

For ores with very high silver content or very high gold grades, the Gold Processing Plant might use the Merrill-Crowe process instead of carbon. Merrill-Crowe uses zinc dust to precipitate gold. It is more efficient than carbon when the dissolved metal concentration is extremely high, as carbon has a maximum loading capacity.

The mining industry is moving towards fully automated CIP circuits in 2025. Manual control of carbon movement often leads to inefficiency. Operators may move carbon too early or too late, affecting recovery. New plants use online carbon concentration meters and gold analyzers.

Question 1: What is the typical gold recovery rate for a CIP plant?

A well-designed CIP plant typically achieves recovery rates between 90% and 95% for non-refractory ores. Factors lowering this include poor grinding size, insufficient leaching time, or carbon fouling.

Question 2: How often does activated carbon need regeneration?

You should regenerate carbon after every desorption cycle. Skipping thermal regeneration leads to a cumulative loss of activity, known as the “heel,” which reduces the plant’s ability to recover gold in subsequent cycles.

Question 3: Can CIP be used for hard rock gold mining?

Yes, CIP is a primary method for Hard Rock Gold Processing Plant operations. The ore must be crushed and ground fine enough to expose the gold particles to the cyanide solution.

The CIP process separates leaching and adsorption to maximize efficiency for clean gold ores. Success depends on rigorous carbon management. You must pre-attrit new carbon to prevent physical loss. You must maintain high oxygen levels to speed up leaching and save cyanide. Finally, you must use high-temperature desorption and thermal regeneration to keep the carbon active. Controlling these variables prevents the invisible loss of gold.

If you are planning a new gold plant or upgrading an existing one, verify your ore mineralogy first. Determine if you have preg-robbing elements. Contact ZONEDING for a detailed mineral processing test. We can design a customized CIP solution that balances tank sizing, oxygenation, and carbon handling to maximize your profitability.

ZONEDING is a professional mineral processing equipment manufacturer in China. Since 2004, we have provided crushing, grinding, and beneficiation solutions to the global mining industry. We manufacture the complete range of equipment for CIP plants, from Jaw Crusher units to elution columns. We focus on providing robust equipment that withstands the harsh conditions of mining sites.

Do not let your gold flow into the tailings dam. Contact us today to discuss your gold recovery requirements and get a technical proposal.

Design a cost-effective limestone crushing plant. Our guide focuses on optimizing equipment configuration and flowcharts to boost yield and lower costs.

View detailsA detailed explanation of a lead-zinc ore processing line. Understand the science of preferential flotation to separate lead (galena) and zinc concentrates.

View detailsUnlock maximum gold recovery. Our guide details a high-yield, high-enrichment placer gold processing scheme, from screening to final concentration.

View detailsThis expert guide covers all mineral grinding mill types (Ball, Raymond, Vertical). Get tips on capacity, fineness, and cost to choose the perfect mill.

View details