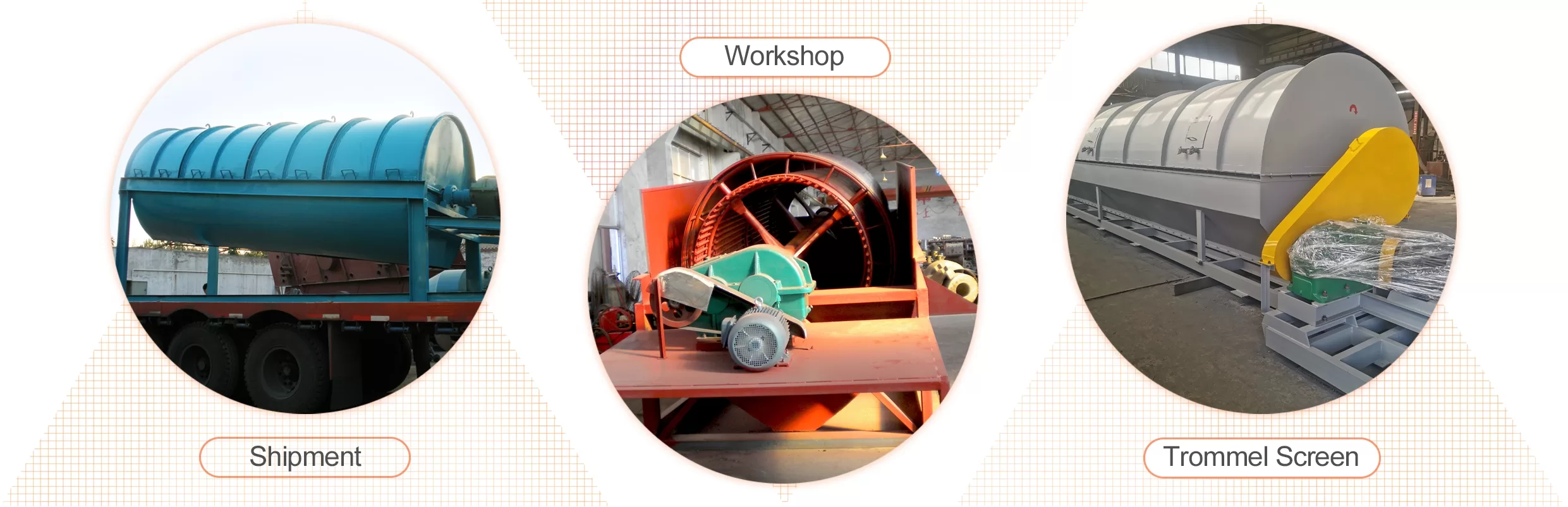

Trommel Screen

Applied Material:nscreening and grading of coal, refractory materials, river sand, sandstone block, heavy soda ash, light soda ash, activated carbon, metal ore powder, etc.- Feed Size: 50–150mm

- Capacity:12–150TPH

Introduction to Trommel Screen

How to Select a Suitable Trommel Screen?

The screen

Converter

The screening effect of the trommel screen

Applications of Trommel Screen

Performance Benefits

Working Principle

Common Faults of Trommel Screen and According Solutions

| Faults | Causes | Solutions |

| Poor-quality finished product from trommel screen | Screen hole is blocked. | Clean the screen hole regularly |

| Low screen efficiency | The material is of high moisture. | Dewater the material ahead of time or increase the mesh of the screen hole. |

| Low rotating speed of the trommel screen | The conveyor belt is loose. | Adjust the equipment transmission belt tightness timely to avoid harm to the machine service life. |

| Hot bearing | The bearing needs to be oiled or cleaned. | Regularly clean and oil the bearing, replace the seal and check if the oil to the bearing meets the standards or not; replace the bearing if it is worn out seriously. |

| Locked trommel screen roller | The seal sleeve maybe blocked. | Clean the shaft sleeve |

| Irregular noise of the rotating trommel screen | Tightness degree of screen tightness, wearing degree of bearing, bolts to hold the parts, etc. | Pay regular check to screen, the bearings, bolts and other parts and timely adjust them according to standards. |

Classic Case

Customer Feedback

Trommel Screen Manufacturer

General Specification

| Model | Yield(m³/h) | Power (kw) | |

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 12 | 100 | 5.5 |

| YTS1240 | 14 | 120 | 5.5 |

| YTS1250 | 15 | 140 | 5.5 |

| YTS1530 | 18 | 150 | 5.5 |

| YTS1540 | 18 | 150 | 7.5 |

| YTS1550 | 20 | 180 | 11 |

| YTS1560 | 22 | 200 | 11 |

| YTS2040 | 25 | 250 | 15 |

| YTS2050 | 30 | 300 | 15 |

| YTS2060 | 35 | 350 | 18.5 |

Related Products

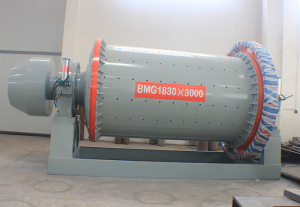

Ball Mill

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Rod Mill

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

Ceramic Ball Mill

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Flotation Machine

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

Magnetic Separator

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Jigging Separator Machine

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet Pan Mill

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking Table

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Hydrocyclone

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine