Conveyor Belt

Applied Material: River Gravel, Granite, Basalt, Quartz, Iron ore, Diabase, Limestone, Coal Gangue etc. in Aggregate Field, Concrete Mixing Plant, Dry Mortar Plant Desulfurization, Quartz Sand Making Plant, etc.- Conveying Speed:1.3-2.0 m/s

- Capacity:30-3000TPH

What is Belt Conveyor?

ZDM Belt Conveyor

Functional Advantages of Belt Conveyor

The working principle of a conveyor belt is as follows:

What Shall Be Paid Attention to When Using Belt Conveyor?

General Specification

| Belt width(mm) | Conveying length(m) Power(kw) | Conveying speed(m/s) | Conveying amount(t/h) | ||

| 400 | ≤10 3 | 12-15 3-4 | 15-30 4-7.5 | 1.25-2.0 | 30-60 |

| 500 | ≤10 3 | 12-15 4-5.5 | 15-30 5.5-7.5 | 1.25-2.0 | 40-80 |

| 650 | ≤10 4 | 12-15 7.5 | 15-30 7.5-11 | 1.25-2.0 | 80-120 |

| 800 | ≤10 4 | 12-15 7.5 | 15-30 7.5-15 | 1.25-2.0 | 120-200 |

| 1000 | ≤10 5.5 | 10-20 7.5-11 | 20-40 11-22 | 1.25-2.0 | 200-320 |

| 1200 | ≤10 7.5 | 10-20 7.5-15 | 20-40 15-30 | 1.25-2.0 | 290-480 |

| 1400 | ≤10 11 | 10-20 15-22 | 20-40 22-45 | 1.25-2.0 | 400-680 |

| 1600 | ≤10 15 | 10-20 22-30 | 20-50 30-75 | 1.25-2.0 | 600-1080 |

| 1800 | ≤10 18.5 | 10-20 30-45 | 20-50 45-110 | 1.0-2.0 | 800-1500 |

| 2000 | ≤10 22 | 10-20 45-55 | 20-50 55-132 | 1.0-2.0 | 1000-2000 |

| 2400 | ≤10 30 | 10-20 55-75 | 20-50 75-185 | 1.0-2.0 | 1500-3000 |

Related Products

Jaw Crusher

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

Sand Making Machine

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

Impact Crusher

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Vibrating Feeder

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machine

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

Vibrating Screen

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

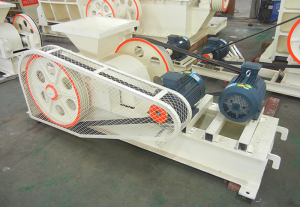

Roll Crusher

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

Fine Crusher

Looking for a high-efficiency fine crusher? Explore our industrial fine crushing machines for sale. Factory-direct pricing and large capacity.

Compound Crusher

Compound Crushers (Vertical Shaft) for efficient fine crushing of medium-hard materials like limestone & clinker. Simple structure, high ratio, ideal for sand making & aggregate. Get Quote!

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine