Tailings Processing

After the mineral processing of the ore, the valuable components are enriched into concentrates, while the remaining substances are referred to as tailings.

To effectively utilize and recover these tailings, concentrators employ a tailings recovery process. This involves reprocessing the various ore tailings. Zoneding Machine specializes in designing tailings processing plants and equipment that are tailored to the specific properties of mineral tailings. They ensure that the tailings are processed in an efficient and environmentally friendly manner, maximizing the extraction of valuable minerals and minimizing waste.

If you are interested in our products, please email us at zd-machine@kssb.cn

Related notes

To improve the gold ore grinding, the customer purchased a fine jaw crusher

How to choose magnesium ore ball mill? The role and advantages of magnesium ore ball mill

Iron Fine Powder Ball Mill Application Scope

Phosphate ball mill working principle, structure, phosphate ball mill steel ball loading capacity

Should I use a ball mill or a rod mill to grind limestone?

Diatomaceous earth ball mill

loading…

已经是到最后一篇内容了!

Related Products

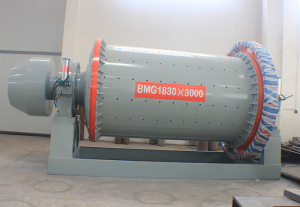

Ball Mill

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Rod Mill

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

Ceramic Ball Mill

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Flotation Machine

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

Magnetic Separator

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Jigging Separator Machine

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet Pan Mill

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Shaking Table

Shaking tables for gold recovery, mineral processing at great prices. Learn more about our gold shaking table, prices, and processing today.

Hydrocyclone

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!

1Scan the codeHello 👋

Can we help you?Open chat

Zoneding Machine

Zoneding Machine