3000 TPD Copper Ore Processing Plant

- Raw Ore: Sulfide Type Copper Ore

- Capacity: 3000 tons per day

- Work Scope: Equipment Supply and Installation

This user is our old customer of ZONEDING, who has been using mineral processing equipment in the main flotation production line for many years. Flotation separation is a widely used method for processing copper ore in copper ore beneficiation plant.

Material Introduction

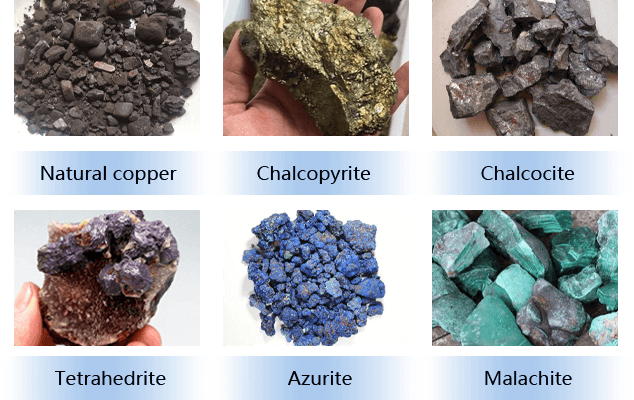

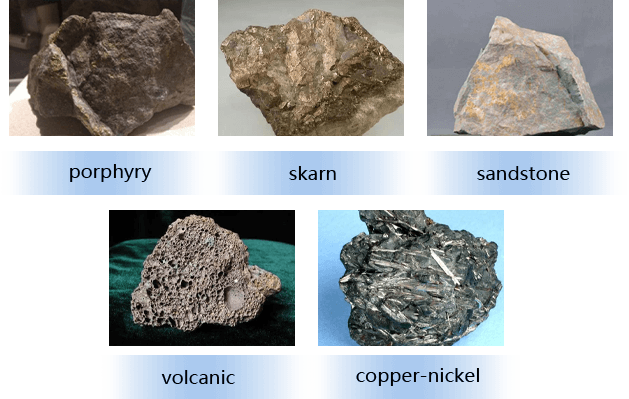

Copper ore is generally a collection of copper sulfides or oxides and other minerals. Industrial copper minerals include: natural copper, chalcopyrite, chalcopyrite, tetrahedrite, azurite, malachite, etc. The main types of copper resources are porphyry, skarn, sandstone, volcanic, copper-nickel, etc.

Chile is currently the country with the richest copper mines, with its reserves accounting for 29% of the world’s total; its output and export volume also rank first in the world; other countries with large reserves include Peru, the United States, Mexico, Indonesia, China, Poland, and Zambia , Russia, Canada, Australia, Kazakhstan, Congo, Philippines, etc.

Industrial copper minerals include

Types of copper resources

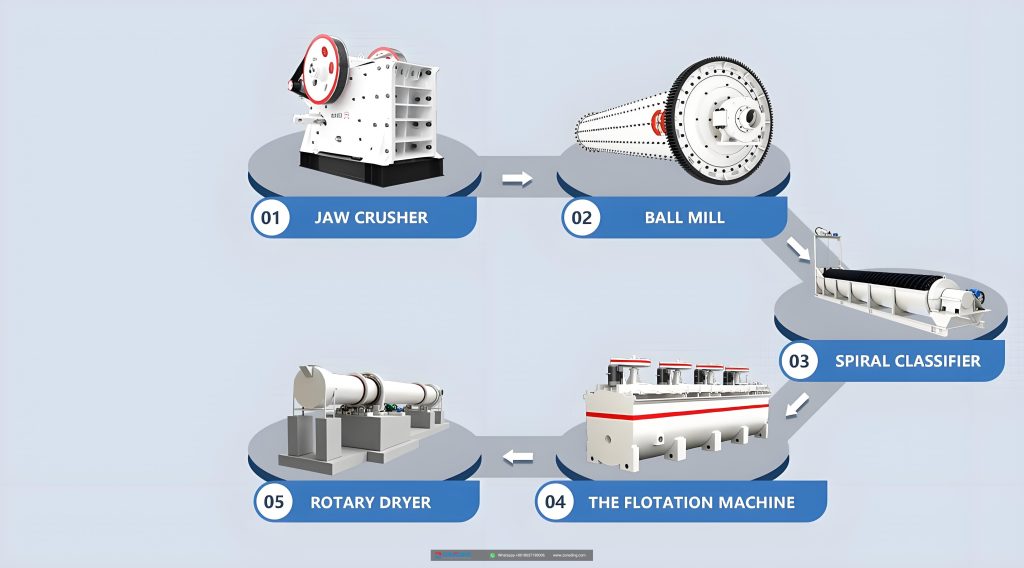

Solution Process

Technical Requirements

1.The flowchart is just for reference.

2.The process is adjustable according to the site requirements, but part placement cannot be changed.

3.Foundation dimensions of equipment are subject to our drawing.

4.Any question please contact us online.

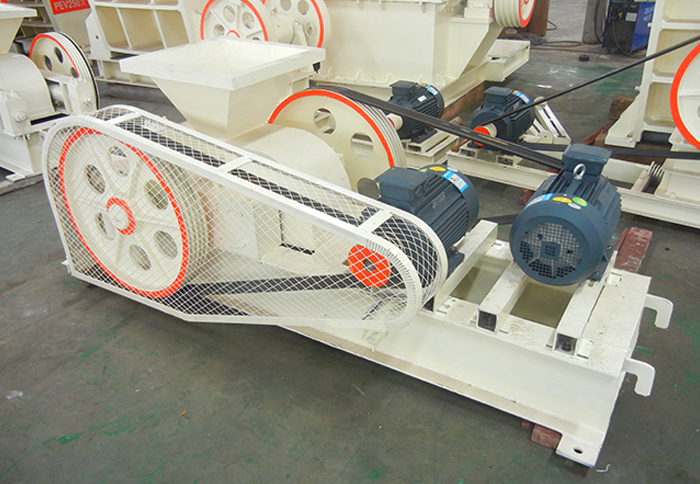

- 1. Crushing: The purpose is to crush the copper ore to an appropriate size, and then proceed to the next part of grinding. The beneficiation equipment used to crush copper ore is mainly a jaw crusher, which is used for primary crushing.

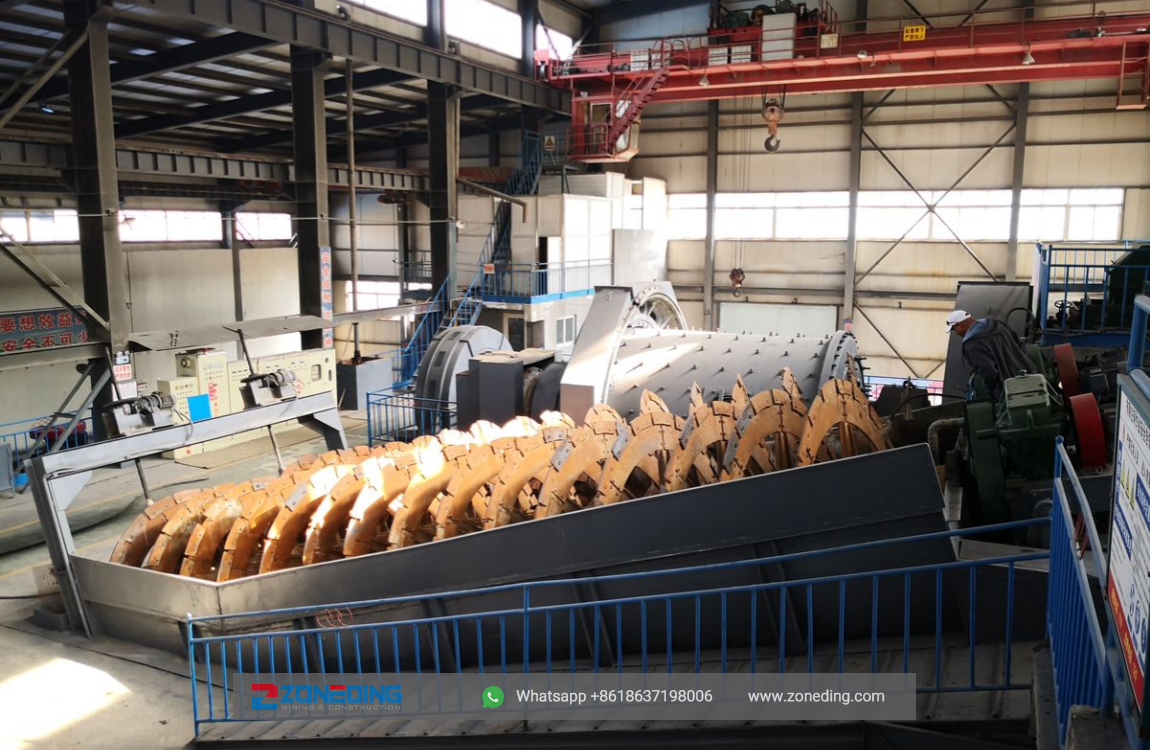

- 2. Grinding: Grinding the crushed part to further process the ore to obtain a smaller size and prepare for the next part of flotation. After the preliminary crushing, the copper ore is uniformly sent to the ball mill by the bucket elevator and belt conveyor, and the ore is crushed and ground by the ball mill; and reasonably classified by the spiral classifier, the slurry that does not meet the flotation requirements is returned re-grind in the ball mill.

- 3. Flotation: The flotation process is an important process of copper ore dressing. The graded pulp material that meets the conditions is sent to the mixing tank, fully mixed and stirred with the reagent, and then sent to the flotation machine for separation and processing to obtain a higher purity copper concentrate slurry.

- 4. Drying: At last, it is preliminarily concentrated and precipitated by a concentrator, and dried by a rotary dryer to obtain copper concentrate powder.

Customer’s Feedback

The production line designed by ZONEDING for our company has obtained high indexes of ore dressing, the grade of concentrate has been increased by more than 50%, the cost of ore dressing has been greatly reduced, and the price of the whole production line is not too expensive, so the economic benefits obtained are very considerable.

Related Products

Jaw Crusher

Reliable Jaw Crushers for efficient primary crushing in mining, quarrying & aggregate production. Heavy-duty design, high throughput.

Cone Crusher

Cone Crusher For Sale: Highly efficient, stable and durable, ideal for all ore crushing needs. It can improve production efficiency and reduce operating costs.

Sand Making Machine

High-efficiency VSI sand making machines for producing premium artificial sand from rock & gravel. Excellent particle shape, low wear cost.

Impact Crusher

PF Series Impact Crusher for secondary crushing of limestone, rock, and efficient recycling of concrete & asphalt. High throughput, excellent shape. Get Specs!

Vibrating Feeder

Looking for a high-performance Vibrating Feeder? Explore our durable industrial feeding machines for mining & aggregate plants.

Sand Washing Machine

Sand Washing Machines (Wheel & Spiral types) to remove impurities & improve sand quality for construction & industry. High cleanliness, reliable performance. Get Your Quote!

Vibrating Screen

The YK series circular vibrating screens are high-performance and suitable for heavy-duty quarrying and aggregate screening operations. Multi-layer screen options are available for precise grading.

Roll Crusher

Smooth Roll Crushers for finer sizing or Toothed Roll Crushers for better grip on materials like coal & shale. Reliable, low maintenance crushers for various industries.

loading…

已经是到最后一篇内容了!

Related Cases

250 t/h Granite Crushing Production Line in Zambia

The processing plant is a good engaged in the construction of special stone processing, production and sales of stone factory, the main products are granite, basalt, river pebbles, etc., has a scientific and reasonable quality mana…

Kazakhstan 150 t/h Copper Ore Crushing Production Project

The company examined the crushing equipment in China for nearly half a year, but was still attracted by the powerful processing capacity and excellent technology of Zoneding, and purchased a 150T/H sand and gravel aggregate produ…

Pakistan 300t/h River Pebble Sand Making Production Line

The customer mainly provides stone and mechanism sand for mixing station, the production line is set up close to the river, and the main reason for purchasing the equipment is that he wants to utilize the river pebbles to produce cru…

Oman 100t/h Complete Limestone Crushing Production Line

The customer learned that 2 years ago a friend from the company purchased a stone crushing line, the model is small, but the operation is very stable, this time introduced to buy a limestone crushing line. Main equipment: PE1200X15…

Malaysia 250 t/h basalt crushing line

The customer is a mining boss in a certain place, already has an iron ore production line, which is a large basalt crushing production line, introduced by peers after inspection or choose to cooperate with our company. Main equipment…

South Africa 300t/h iron ore crushing line

The customer enterprise is a well-known local mining group to participate in the investment and construction of iron ore production line, the company has strong strength and rich experience. The customer has purchased a jaw crusher f…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine